Planetary gear train of automatic transmission for vehicles

A technology of automatic transmission and planetary gear system, which is applied in vehicle gearboxes, vehicle components, gear transmissions, etc., can solve the problems of linearity deterioration of eight-speed automatic transmissions, and achieve reduced torque load, minimized operation, and reduced resistance The effect of loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example

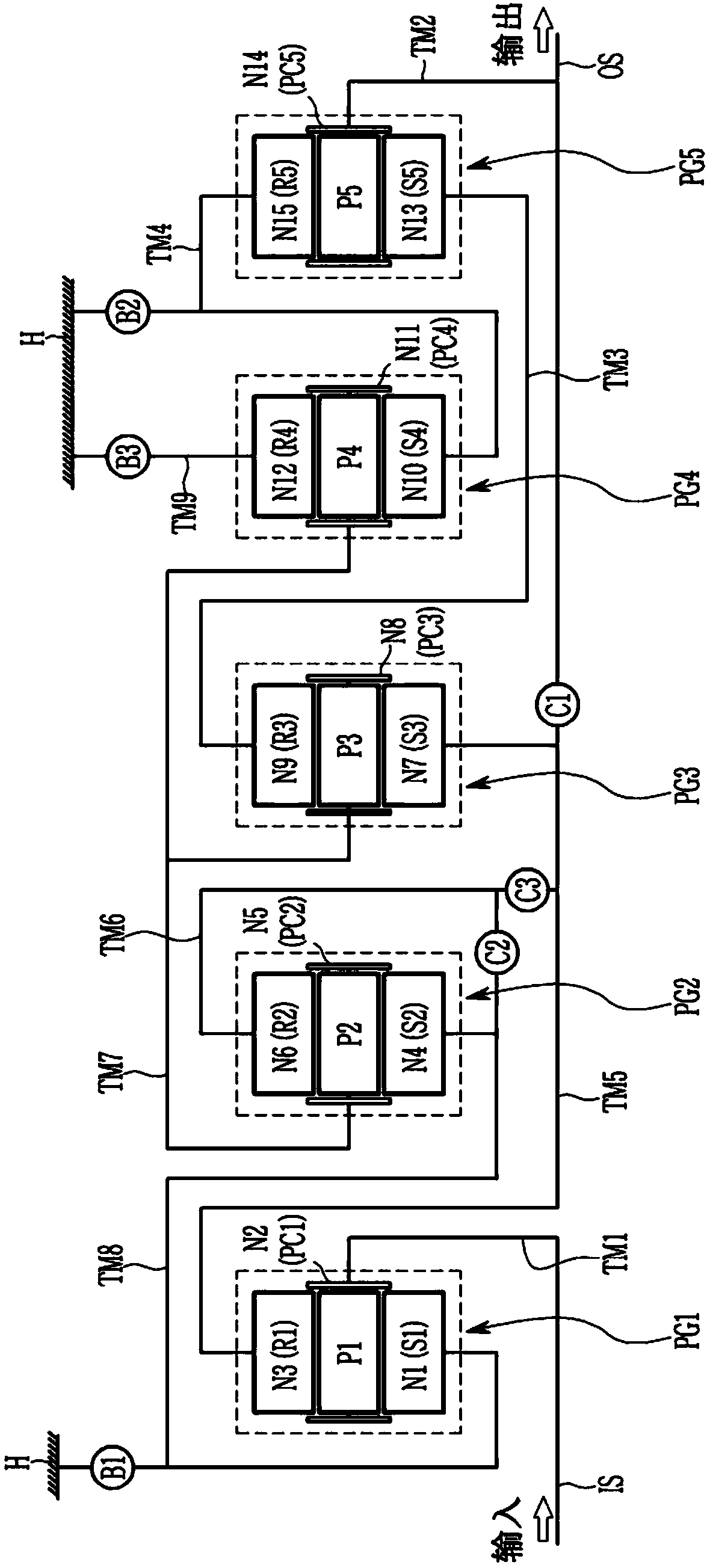

[0132] In the third embodiment, as in the first embodiment, when the second clutch C2 is operated, the second planetary gear set PG2 is integrally rotated.

[0133] Such a second embodiment differs from the first embodiment only in the arrangement of the second clutch C2, and shows the same connection relationship between the nine shafts TM1 to TM9, retaining the two clutches C1 and C3, and the three Brakes B1 to B3 thus provide the same operation.

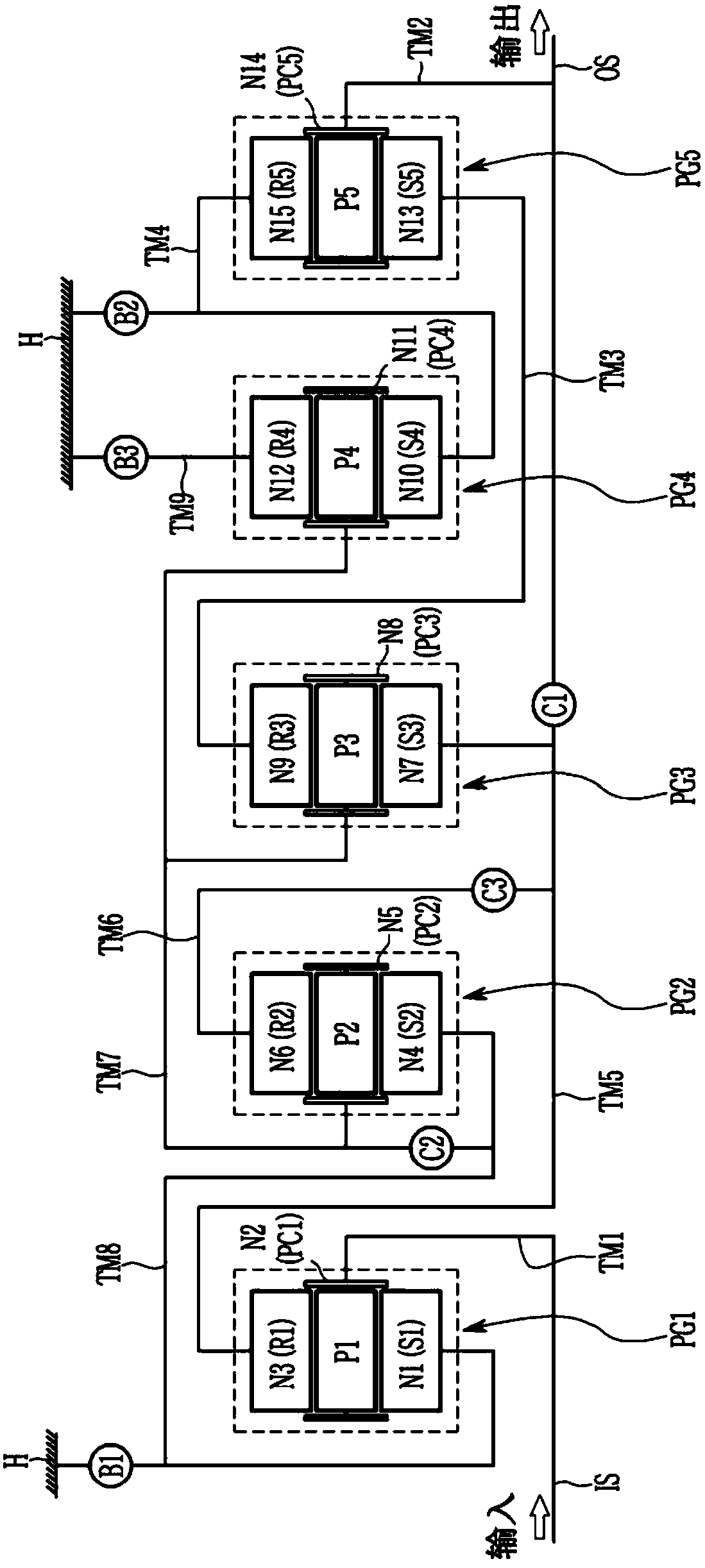

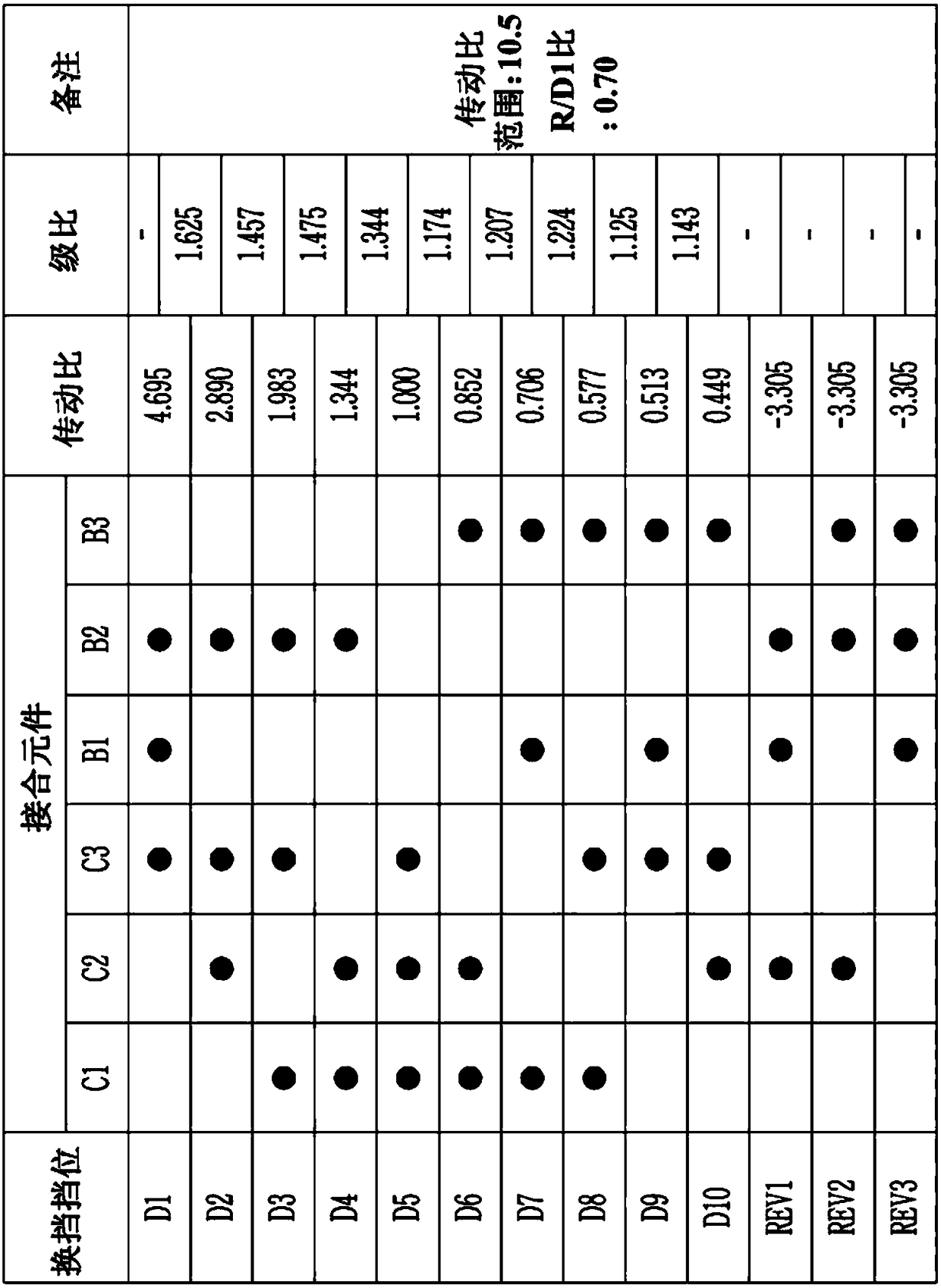

[0134] As described above, the planetary gear trains of the first to third exemplary embodiments of the present invention utilize five planetary gear sets PG1 , PG2 , PG3 , PG4 and PG5 composed of three clutches C1 , C2 and C3 and the six engagement elements of the three brakes B1, B2 and B3, and thereby achieve ten forward speeds and at least one reverse speed.

[0135] In addition, a gear ratio range of at least 10.5 can be achieved to enhance the engine driving efficiency, and the linearity of the gear ratio of the shifting gears

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap