Antistatic device and substrate machining apparatus comprising the antistatic device

A processing device and anti-static technology, applied in the direction of stone processing equipment, fine working devices, circuits, etc., can solve the problems such as the increase of small scars, reduce the yield and influence, and achieve the effect of high-efficiency removal of static electricity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Hereinafter, an embodiment of an antistatic device and a substrate processing apparatus incorporating the antistatic device according to the present invention will be described in detail with reference to the accompanying drawings.

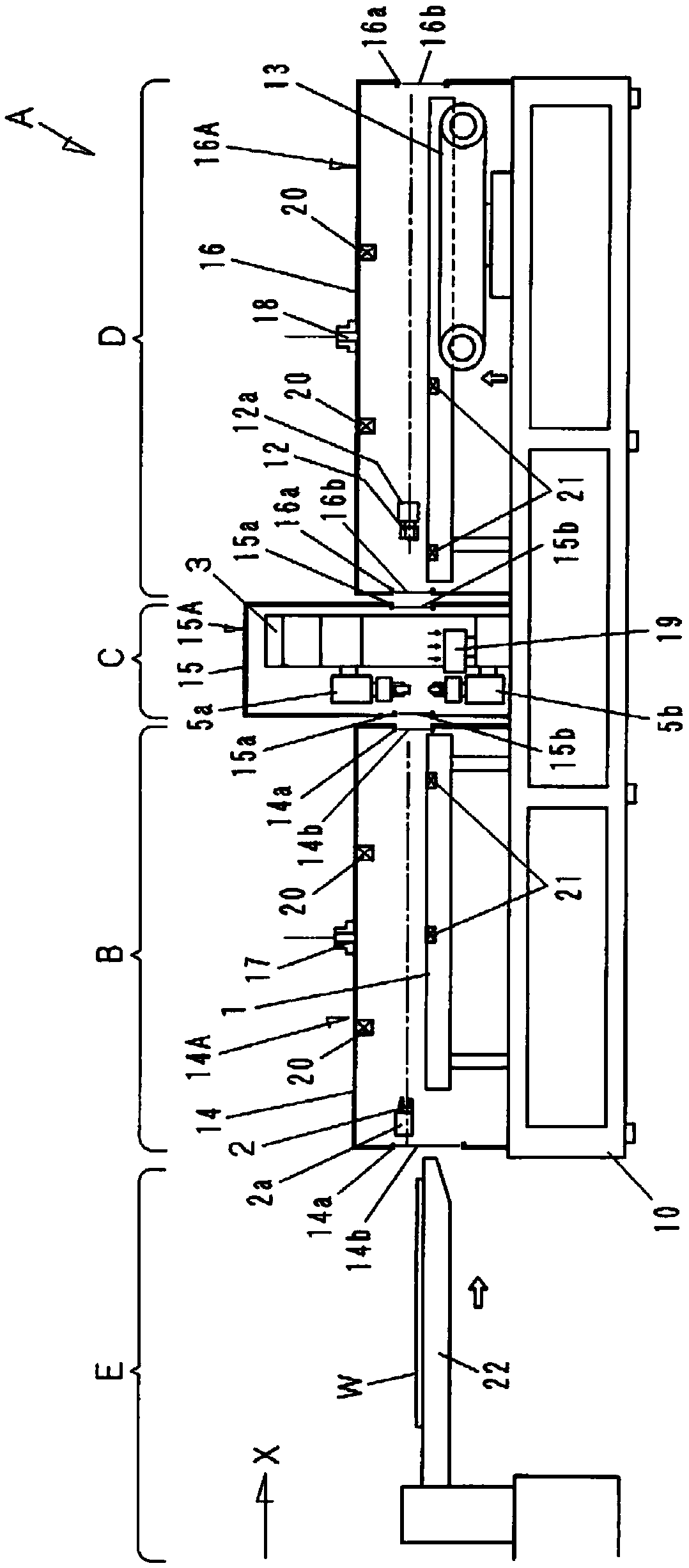

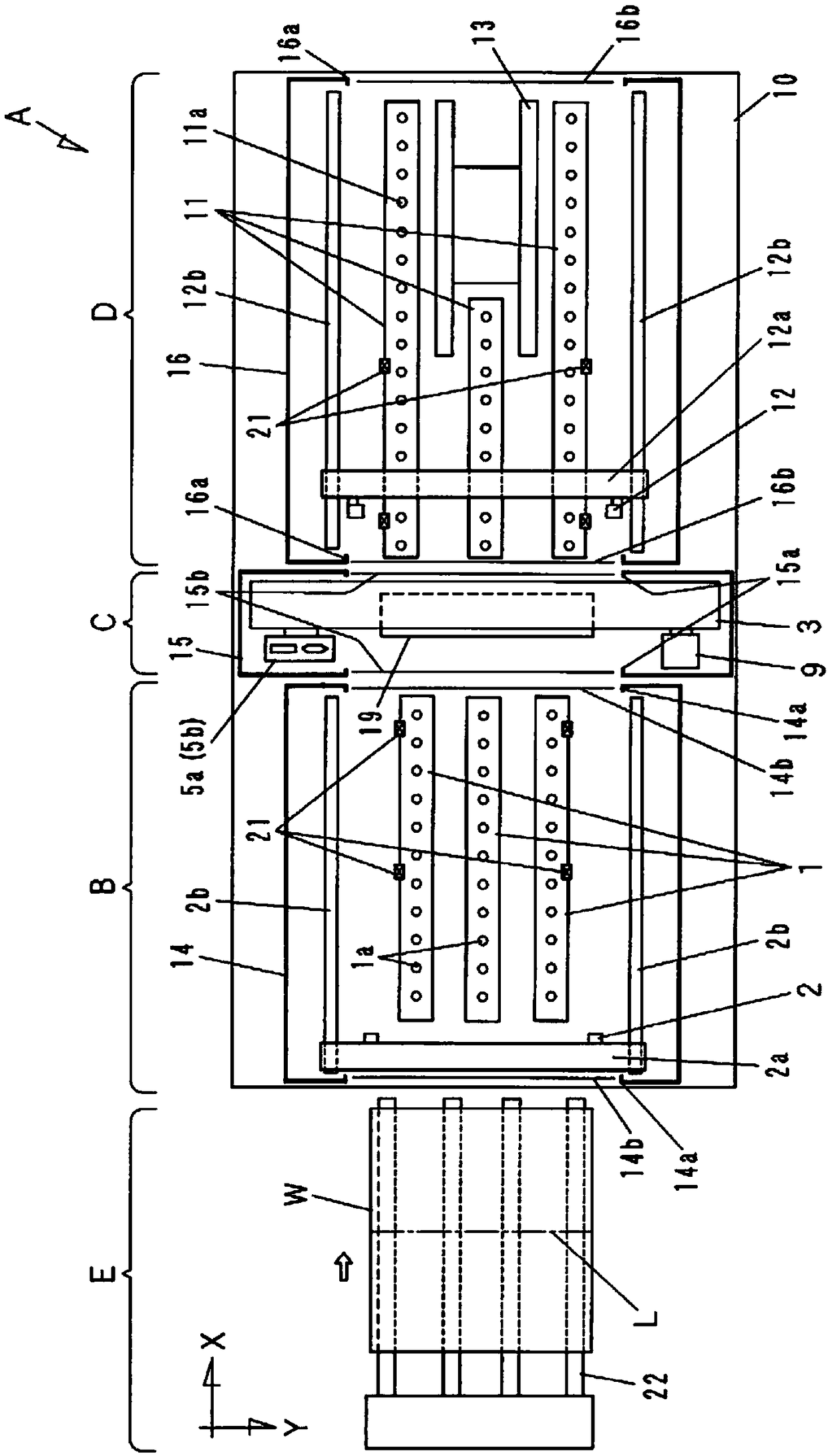

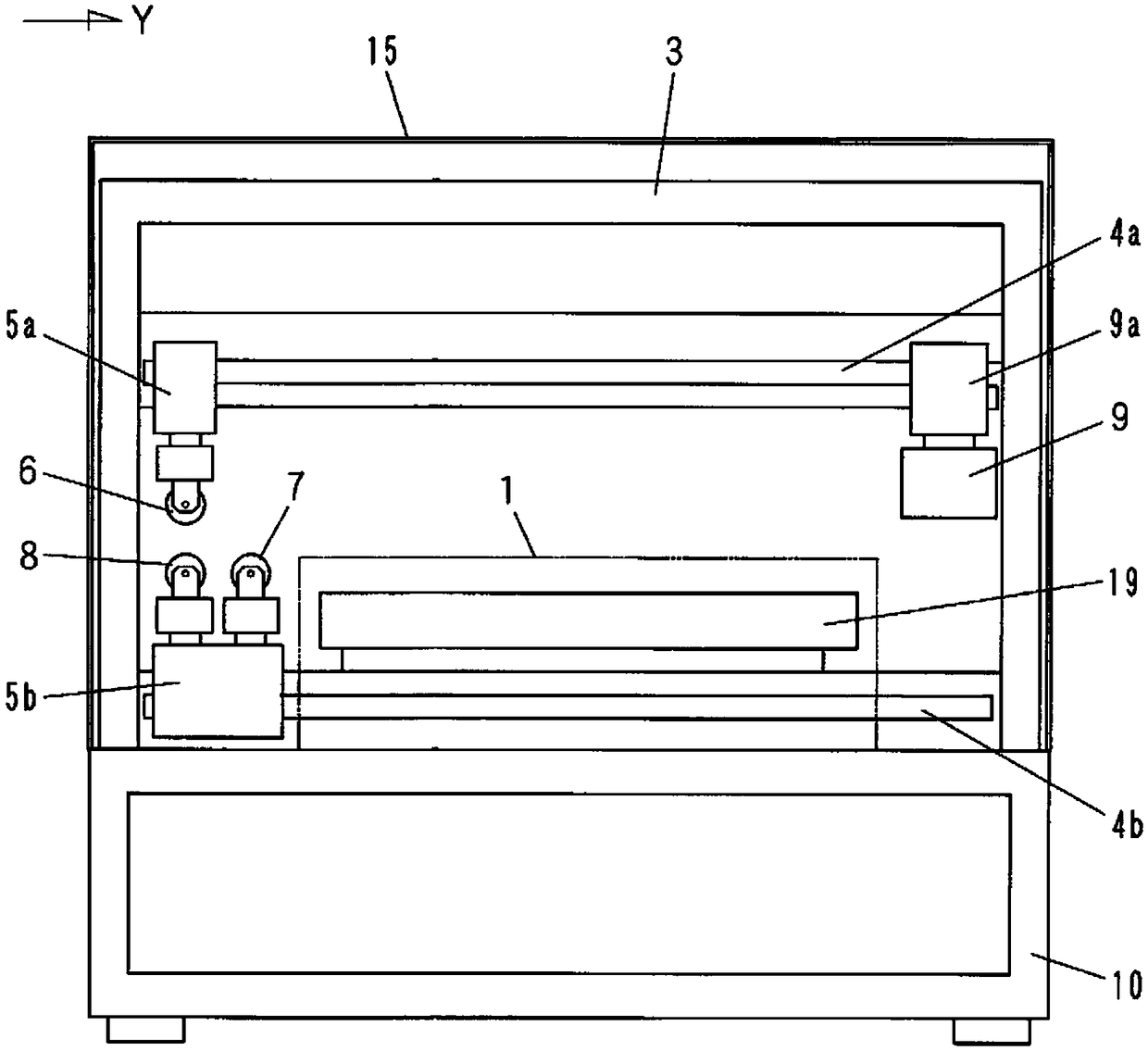

[0040] figure 1 It is an overall schematic side view showing a substrate processing apparatus A including an antistatic device according to the present invention, figure 2 for its top view.

[0041] The substrate processing apparatus A has an upstream conveying part B, a scoring mechanism part and / or a cutting mechanism part C, and a downstream conveying part D. The upstream conveying part B linearly conveys the substrate W to be processed from upstream to downstream in a horizontal posture, and the The scribing mechanism part and / or the cutting mechanism part C processes a scribe line on the back surface of the conveyed substrate W in a direction perpendicular to the conveyance direction, and serves as a substrate processing part that d

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap