Gas filling device for wafer box and gas filling system

A filling system and filling device technology, applied in gas treatment, electrical components, transportation and packaging, etc., can solve the problems of reduced production efficiency, poor product yield, short longest waiting time, etc., to reduce wafer defects Probability of generation, effect of improving manufacturing yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

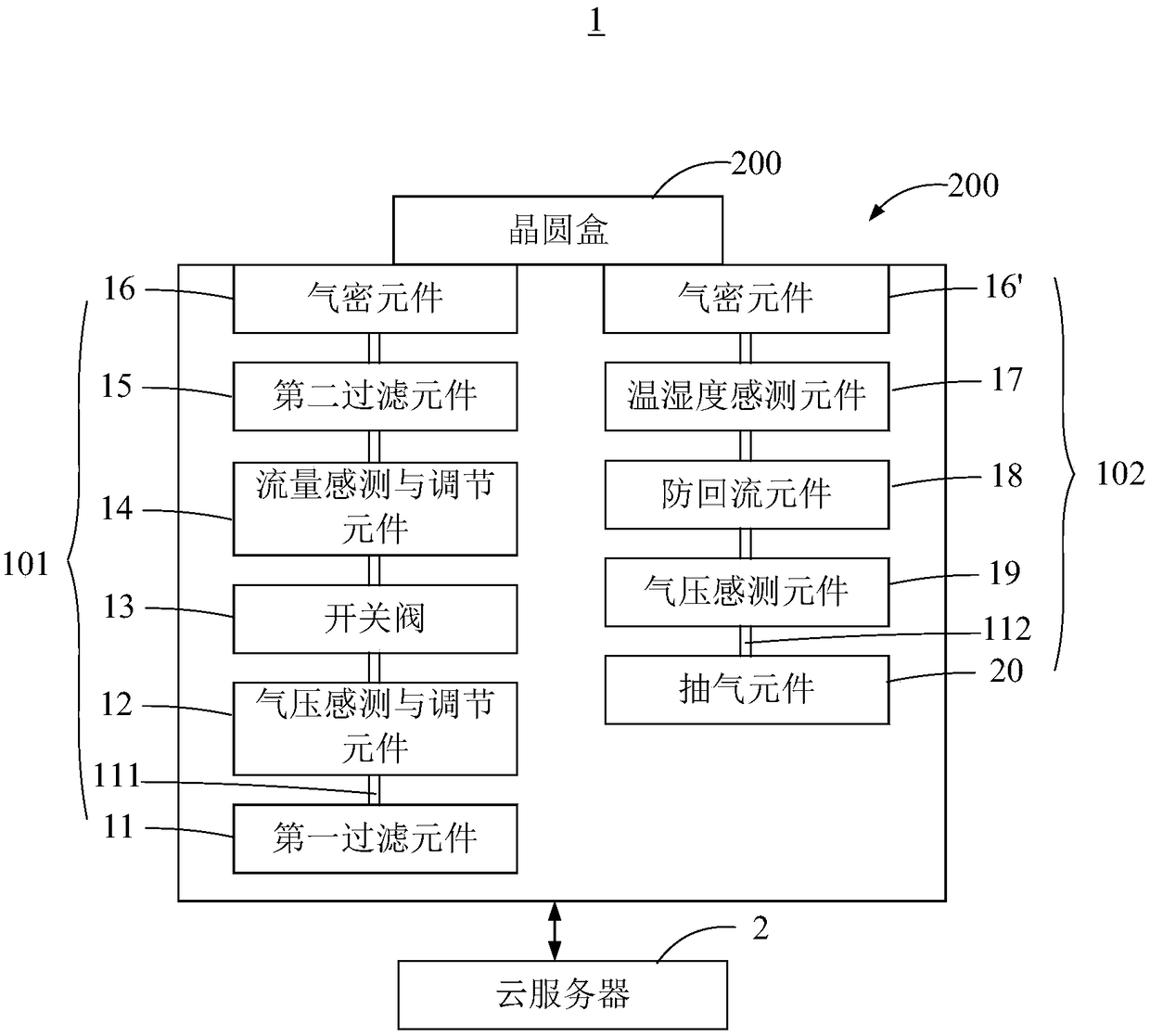

[0015] see figure 1 , a gas filling system 1 according to a preferred embodiment of the present invention includes a gas filling device 100 and a wafer cassette 200 connected to the gas filling device 100 .

[0016] The gas filling device 100 includes an inflatable component 101 and an exhaust component 102 . The inflatable component 101 is used for inflating the gas meeting the requirements of humidity and air pressure into the wafer cassette 200 when a trigger command is received. The gas pumping component 102 is used for pumping out the gas in the wafer box 200 when the gas filling component 101 starts filling the gas into the wafer box 200 , and detecting the humidity and temperature of the extracted gas.

[0017] In this embodiment, the gas filling device 100 communicates with a cloud server 2 via wire or wirelessly. The cloud server 2 is used to send the trigger command to the inflatable assembly 101 and the air extraction assembly 102 at the same time, thereby informing

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap