Damp agglomerated feed crushing and drying equipment for animal husbandry

A drying equipment and animal husbandry technology, applied in drying, drying machine, lighting and heating equipment and other directions, can solve the problems of broken feed that cannot be shaken, short processing time for crushing, and long processing time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

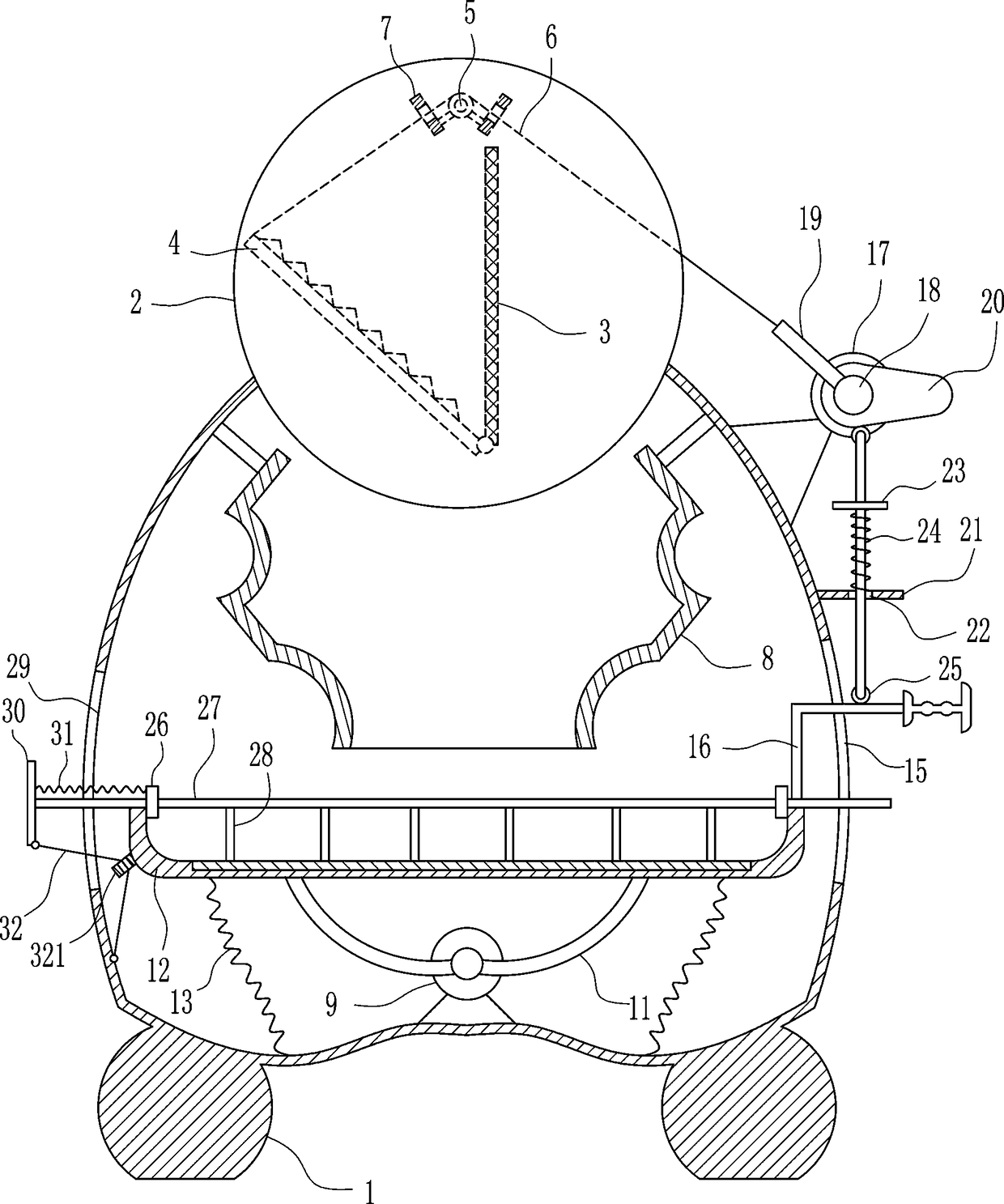

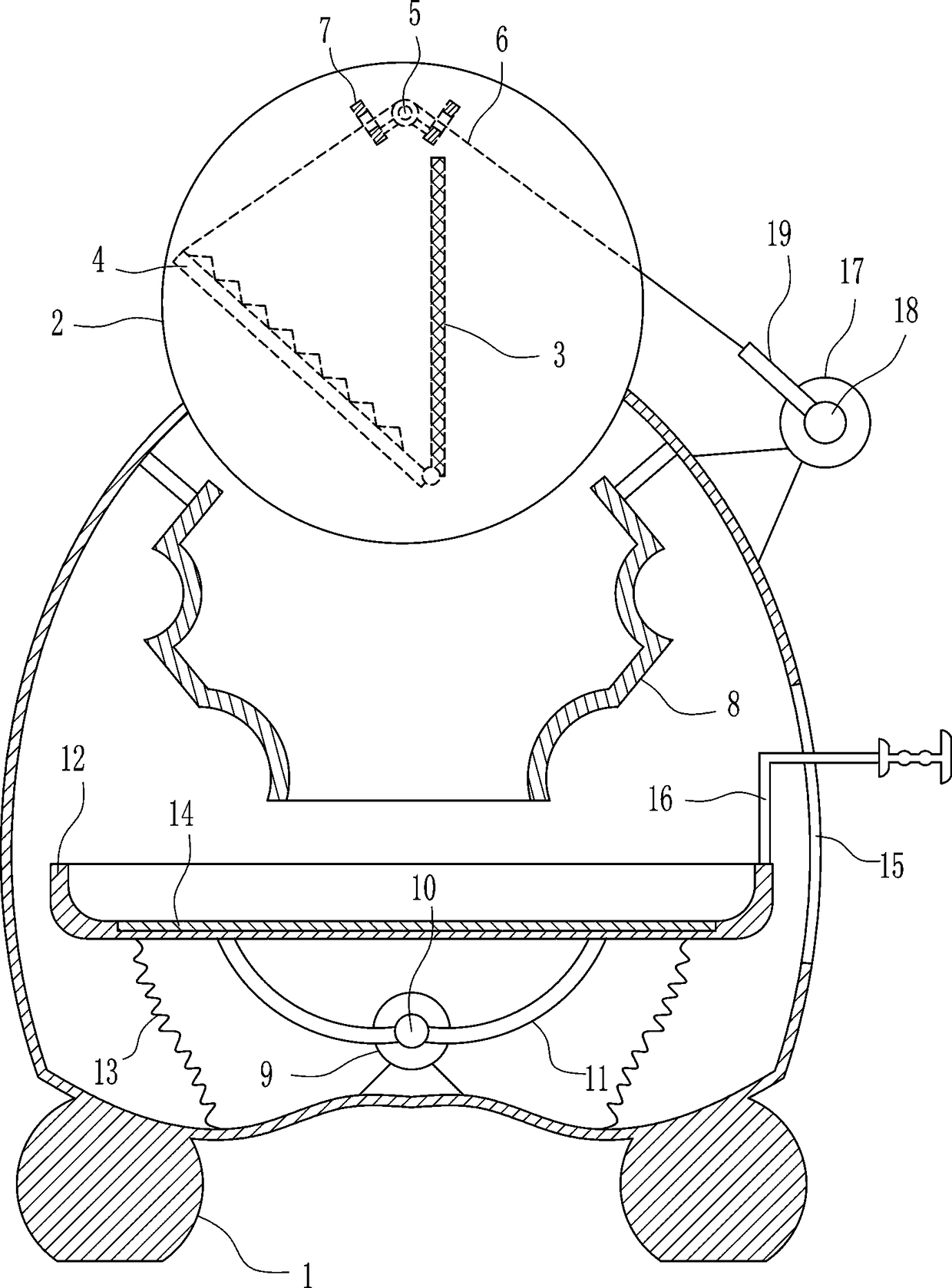

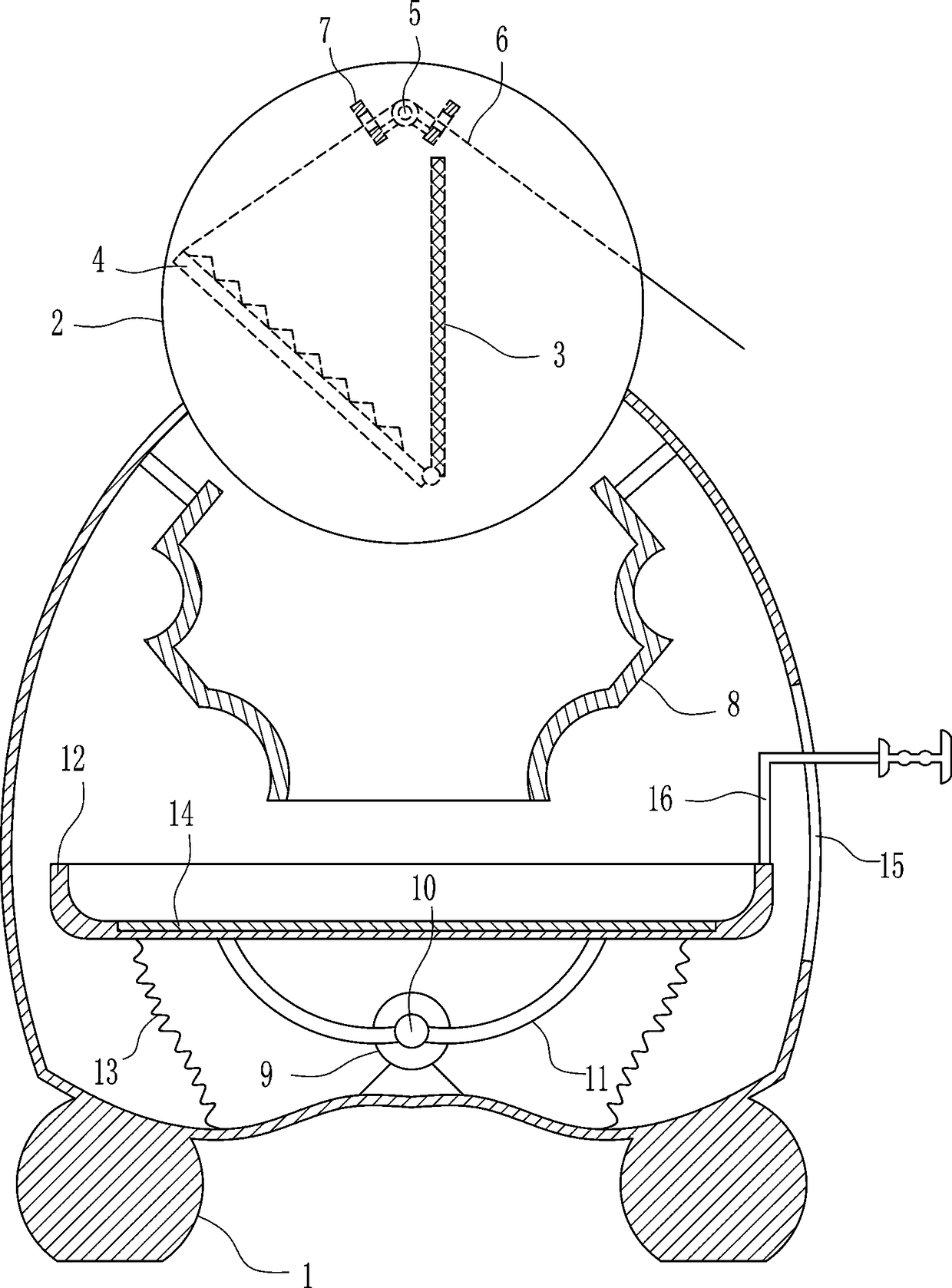

[0023] A damp caking feed crushing and drying equipment for animal husbandry, such as Figure 1-5 As shown, it includes a mounting frame 1, a mounting plate 2, a first mesh plate 3, a swinging mesh plate 4, a guide wheel 5, a first steel wire rope 6, a first guide sleeve 7, a discharge frame 8, a bearing seat 9, a first Rotating bar 10, connecting rod 11, swing frame 12, first spring 13, heating plate 14 and swing bar 16, between the left and right two wall tops of mounting frame 1, front and rear symmetry is connected with mounting plate 2, and the mounting plate 2 of front and rear sides The middle of the right part of the inner side is connected with the first net plate 3, and the bottom end of the first net plate 3 is connected with the swing net plate 4 in a rotational manner. 2 The left and right sides of the upper part of the inner side are obliquely connected with the first guide sleeve 7, and the inner side of the installation plate 2 between the two first guide sleeves

Embodiment 2

[0025] A damp caking feed crushing and drying equipment for animal husbandry, such as Figure 1-5As shown, it includes a mounting frame 1, a mounting plate 2, a first mesh plate 3, a swinging mesh plate 4, a guide wheel 5, a first steel wire rope 6, a first guide sleeve 7, a discharge frame 8, a bearing seat 9, a first Rotating bar 10, connecting rod 11, swing frame 12, first spring 13, heating plate 14 and swing bar 16, between the left and right two wall tops of mounting frame 1, front and rear symmetry is connected with mounting plate 2, and the mounting plate 2 of front and rear sides The middle of the right part of the inner side is connected with the first net plate 3, and the bottom end of the first net plate 3 is connected with the swing net plate 4 in a rotational manner. 2 The left and right sides of the upper part of the inner side are obliquely connected with the first guide sleeve 7, and the inner side of the installation plate 2 between the two first guide sleeves 7

Embodiment 3

[0028] A damp caking feed crushing and drying equipment for animal husbandry, such as Figure 1-5 As shown, it includes a mounting frame 1, a mounting plate 2, a first mesh plate 3, a swinging mesh plate 4, a guide wheel 5, a first steel wire rope 6, a first guide sleeve 7, a discharge frame 8, a bearing seat 9, a first Rotating bar 10, connecting rod 11, swing frame 12, first spring 13, heating plate 14 and swing bar 16, between the left and right two wall tops of mounting frame 1, front and rear symmetry is connected with mounting plate 2, and the mounting plate 2 of front and rear sides The middle of the right part of the inner side is connected with the first net plate 3, and the bottom end of the first net plate 3 is connected with the swing net plate 4 in a rotational manner. 2 The left and right sides of the upper part of the inner side are obliquely connected with the first guide sleeve 7, and the inner side of the installation plate 2 between the two first guide sleeves

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap