Pulper oven

A technology for ovens and cabinets, applied in drying, dryers, progressive dryers, etc., can solve the problems of heating temperature not reaching the required temperature, loss of energy, etc., achieve low cost, reduce production cost, dry uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

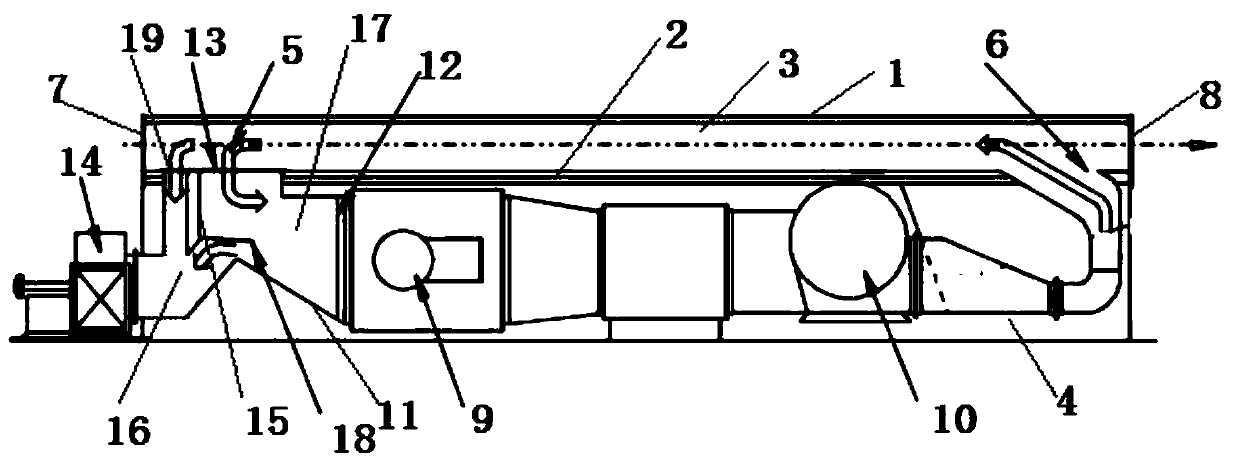

[0011] refer to figure 1 , the present invention proposes a pulper oven, including a box body 1 and an exhaust fan 14 installed outside the box body 1, wherein:

[0012] The inside of the cabinet 1 is provided with a partition 2 arranged horizontally. The partition 2 divides the interior of the cabinet 1 into a drying chamber 3 and a heating chamber 4 arranged up and down. Suction port 5, blower port 6 of chamber 4, steel wire mesh 13 is installed in the suction port 5. The box body 1 is provided with a yarn inlet 7 and a yarn outlet 8 communicating with the drying chamber 3 .

[0013] The heating chamber 4 is provided with a gas burner 9 and a blower 10, the air inlet of the gas burner 9 is connected with the suction port 5, the air outlet of the gas burner 9 is connected with the air inlet of the blower 10, and the air outlet pipeline of the blower 10 Connect with the air outlet 6.

[0014] A side cover 11 is provided near the suction port 5 in the heating chamber 4 , one en

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap