Electric appliance room of water heater and water heater

A technology for electrical equipment room and water heater, which is applied in the direction of fluid heater, lighting and heating equipment, etc. It can solve the problems of the decline of the inner tank’s thermal insulation performance, and achieve thinner and smaller size, smaller overall length, and avoid the change of internal space. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to enable those skilled in the art to better understand the technical solution of the present invention, the technical solution of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

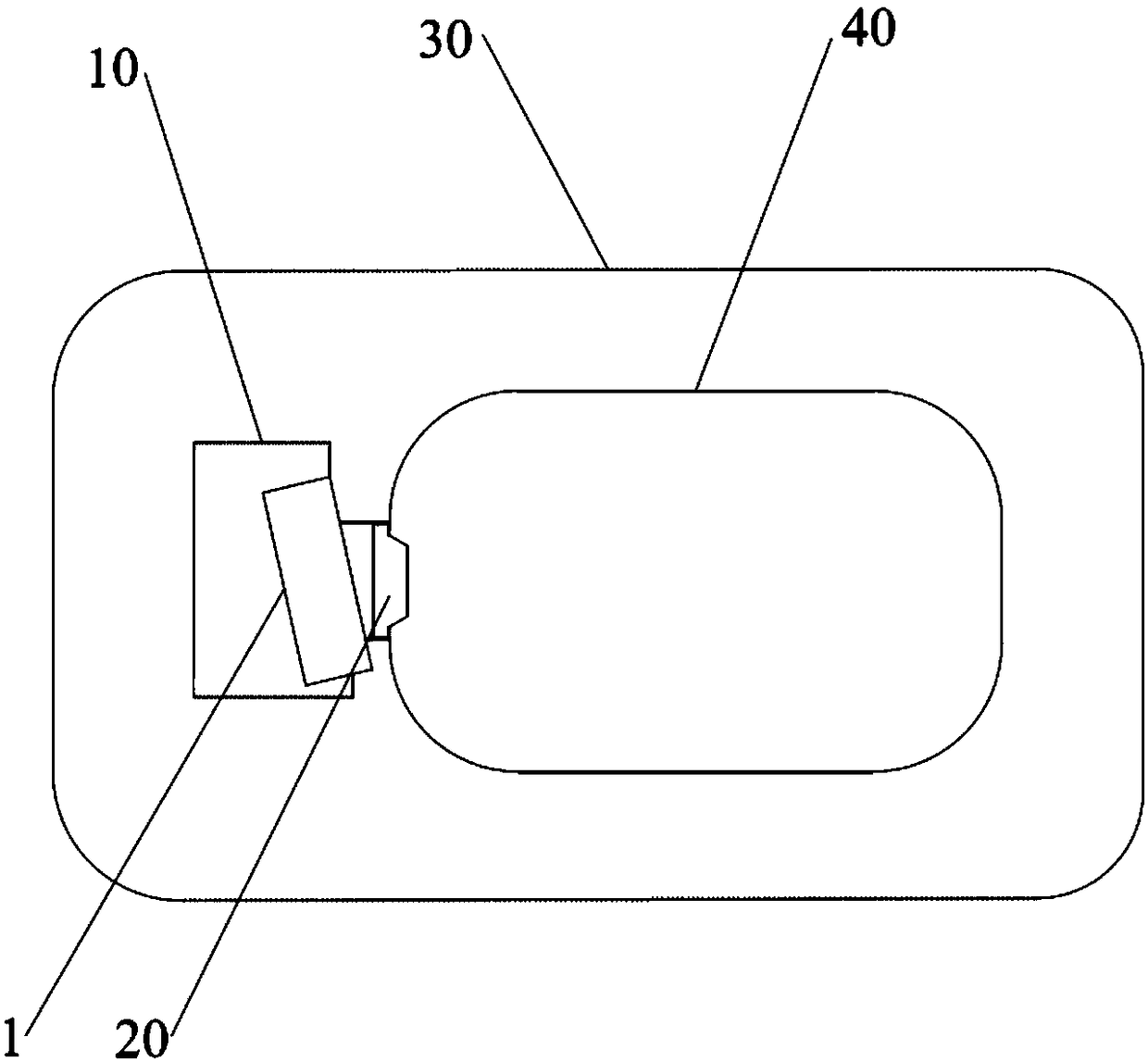

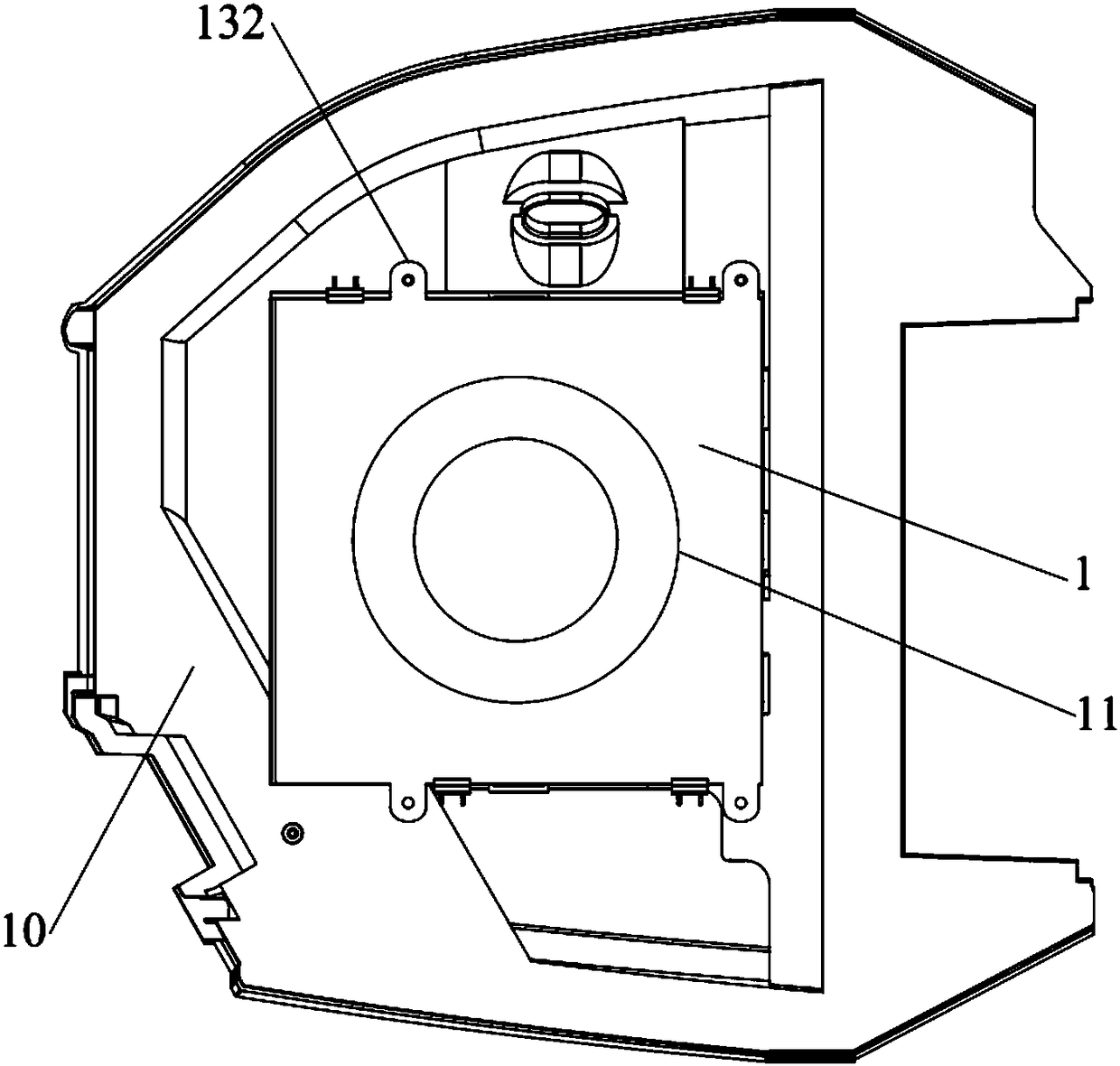

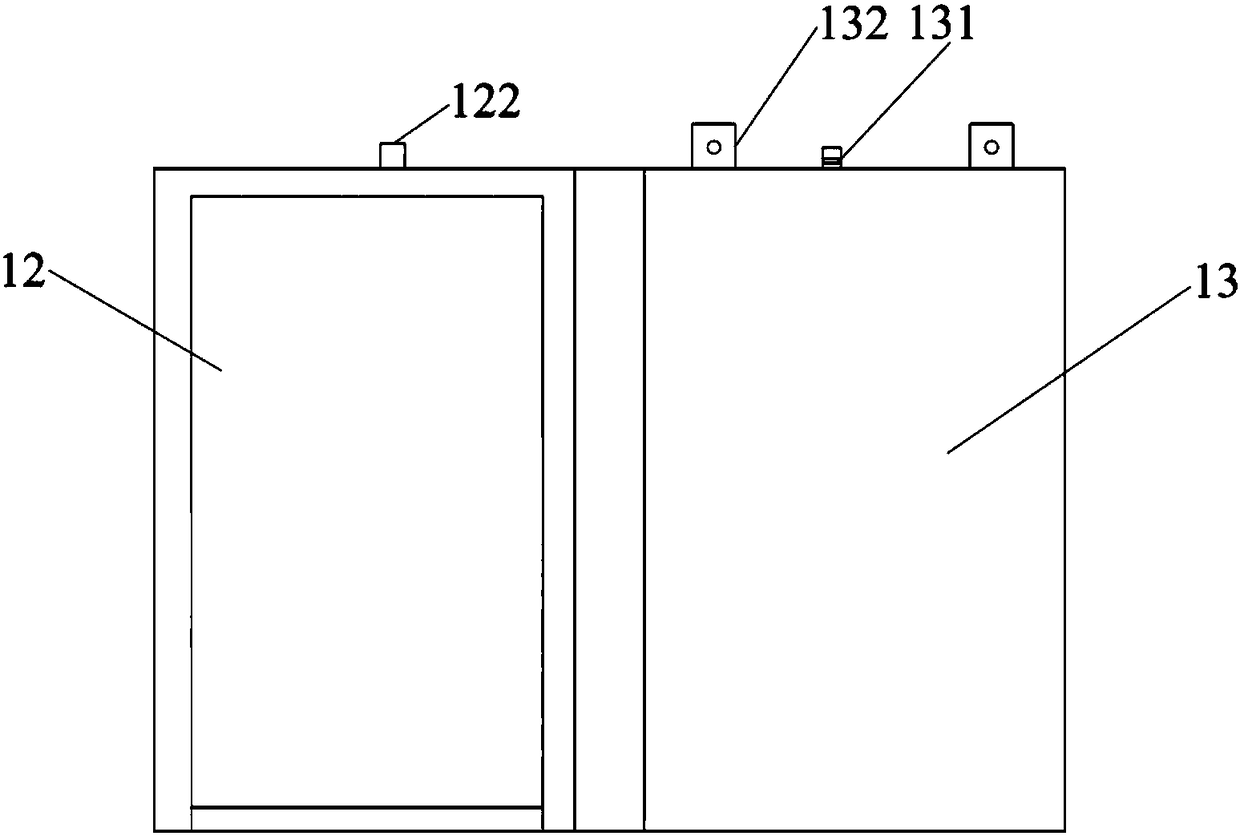

[0028] This embodiment provides a water heater electrical room, such as Figure 1-Figure 4 As shown, the electrical appliance room 10 is installed with a thermal insulation box 1 clamped on the outside of the inner tank flange 20, and the thermal insulation box 1 is provided with a vacuum insulation panel (not shown in the figure). Wherein, the heat preservation box 1 is used for connecting the flange 20 of the inner tank. In addition, the heat preservation box 1 also has a protection function to prevent the vacuum insulation panel from being damaged due to collision. In this embodiment, the heat preservation box 1 is set on the outside of the inner tank flange 20, so that the inner tank fla

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap