Blast furnace soft water leakage detecting device

A blast furnace and soft water technology, applied in the direction of cooling devices, etc., can solve the problems of hidden dangers of system stability, invisibility, and a large number of coolers connected in series, and achieve the effects of simple process, elimination of damage, and centralized maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

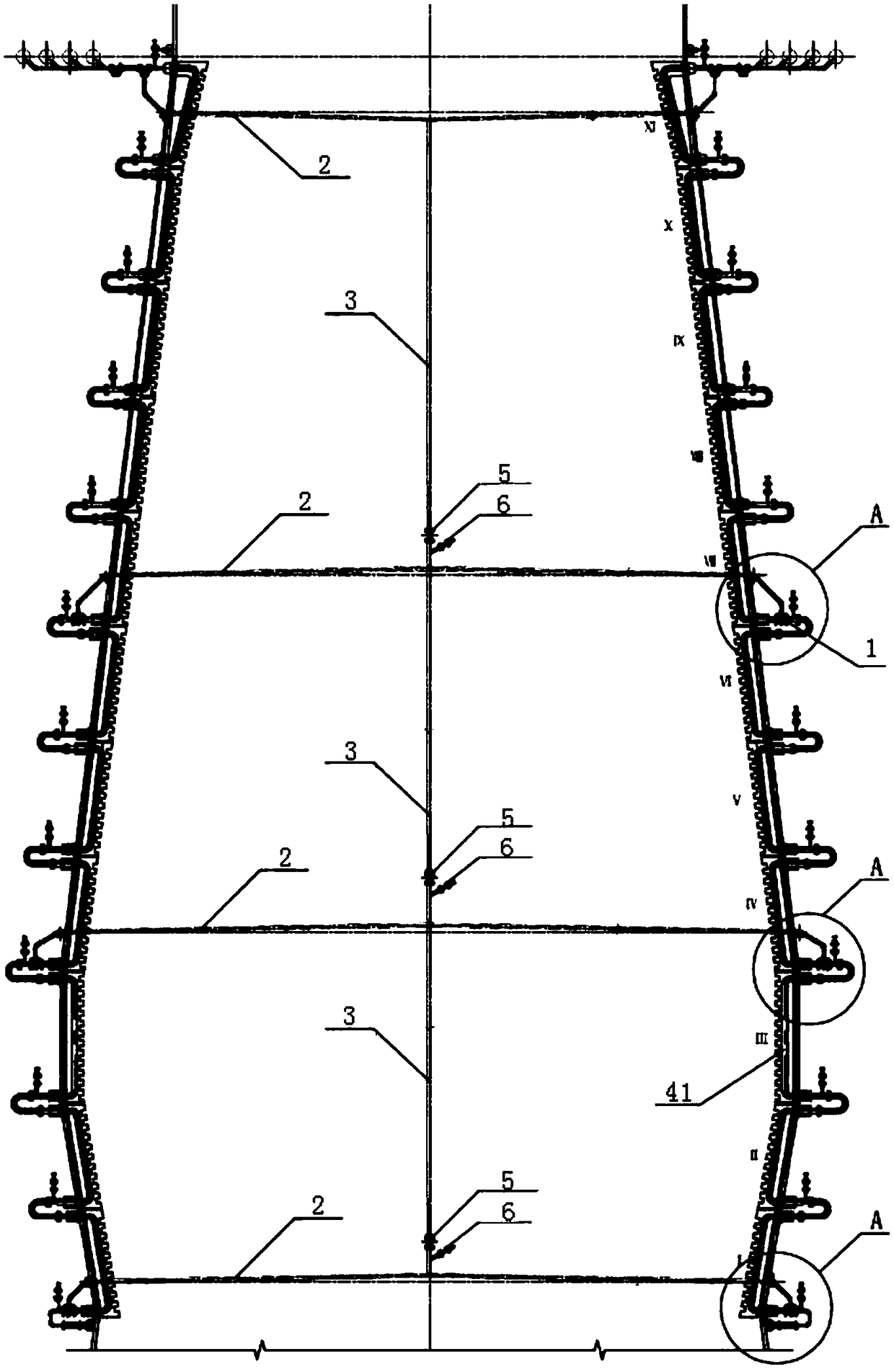

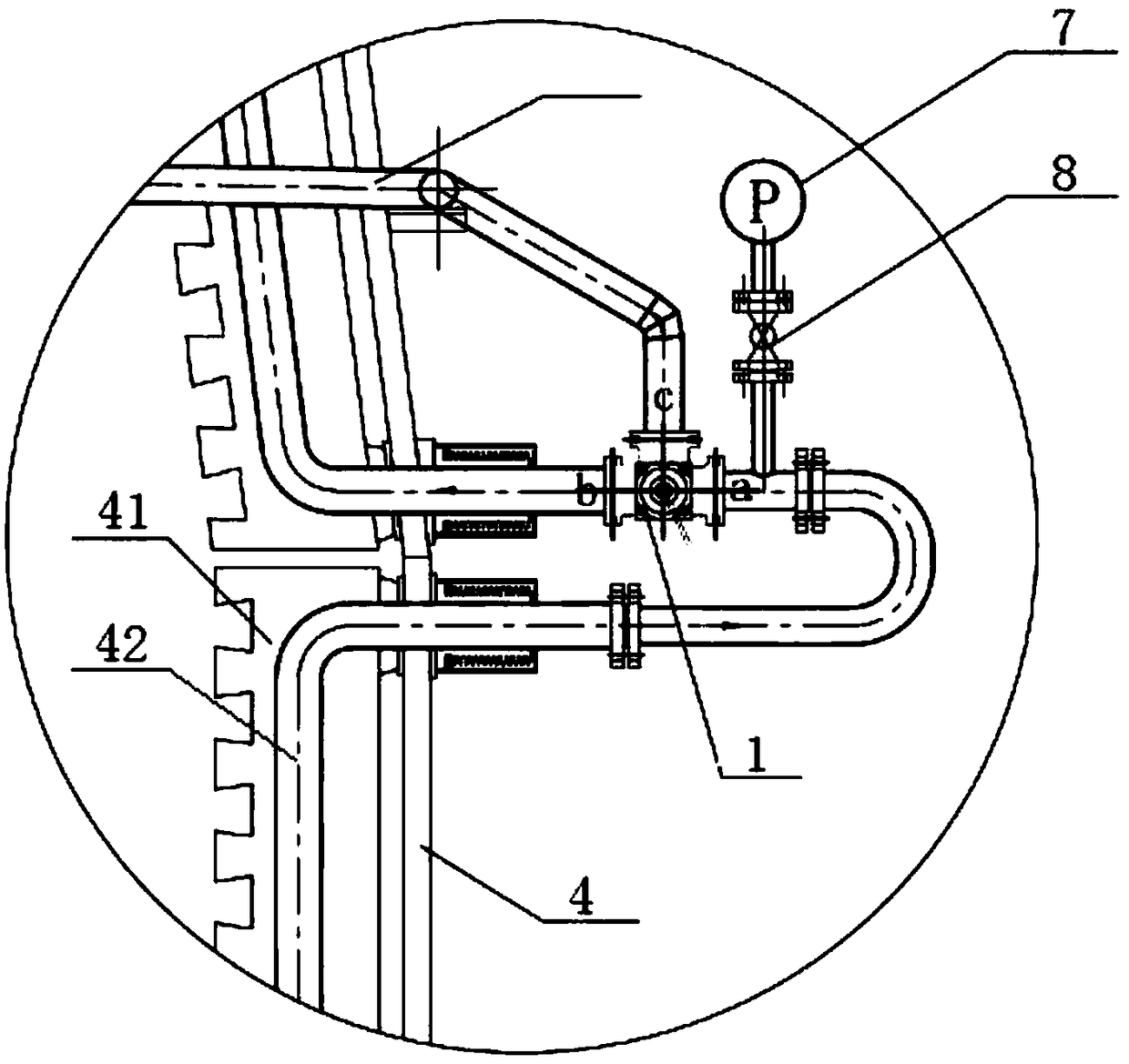

[0021] from Figure 1-2 It can be seen that a blast furnace soft water leak detection device in this embodiment includes a blast furnace body 4, an inner interval of the blast furnace body 4 is provided with a ring pipe 2, and an outer interval of the blast furnace body 4 is provided with a three-way valve piping 1 and an outer ring pipe 2. One end passes through the blast furnace body 4 and communicates with the three-way valve piping 1. The other end of the ring pipe 2 is connected with a communication pipe 3. The adjacent ring pipe 2 is connected through the communication pipe 3. The outer surface of the communication pipe 3 is equipped with a shut-off valve 5 and an exhaust valve 6. The flow of cooling water can be blocked by closing the shut-off valve 5, and the water vapor can be discharged by opening the exhaust valve 6. The bottom end of the ring pipe 2 is connected to the three The pipe 1 is connected to the valve, and the bottom end of the ring pipe 2 is inclined to fac

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap