Perovskite solar cell and a preparation method

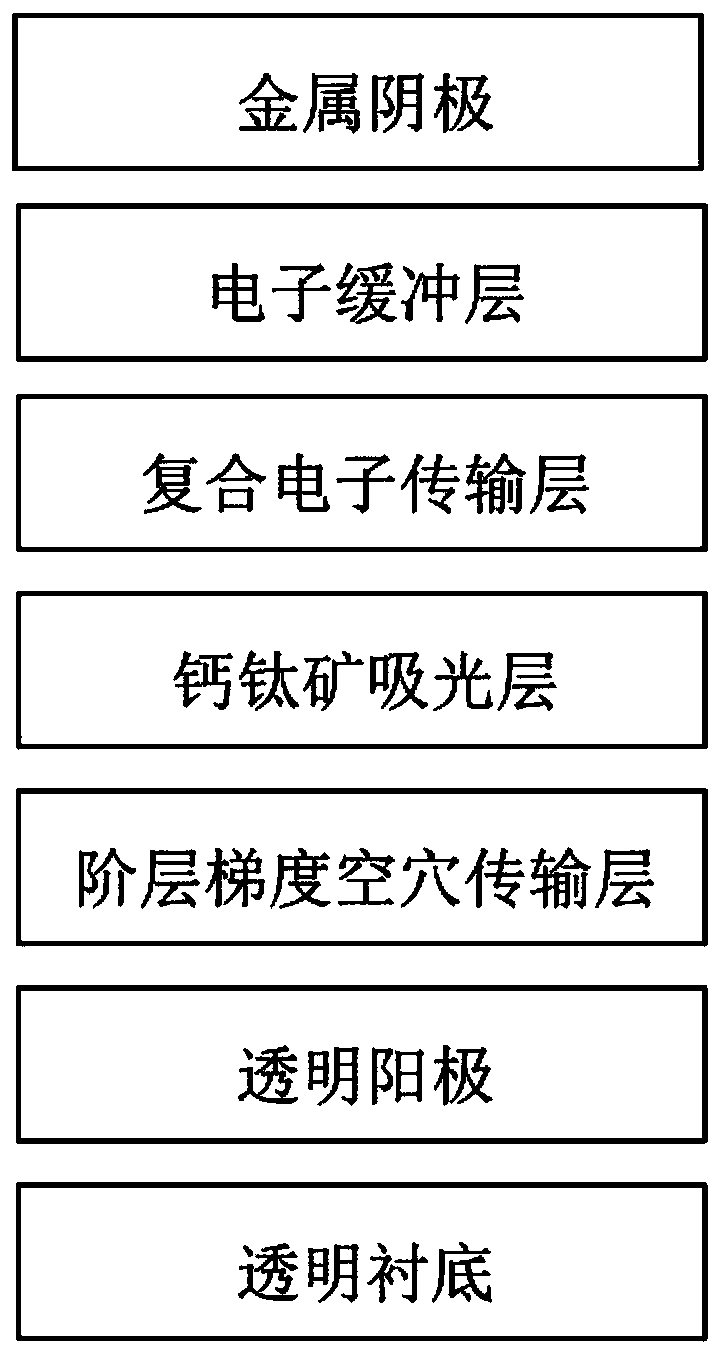

A solar cell and perovskite technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of perovskite active layer energy level mismatch, device open circuit voltage and low photoelectric conversion efficiency, etc., to improve the open circuit voltage. VOC and photoelectric conversion efficiency, solve poor stability, improve the effect of energy level matching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

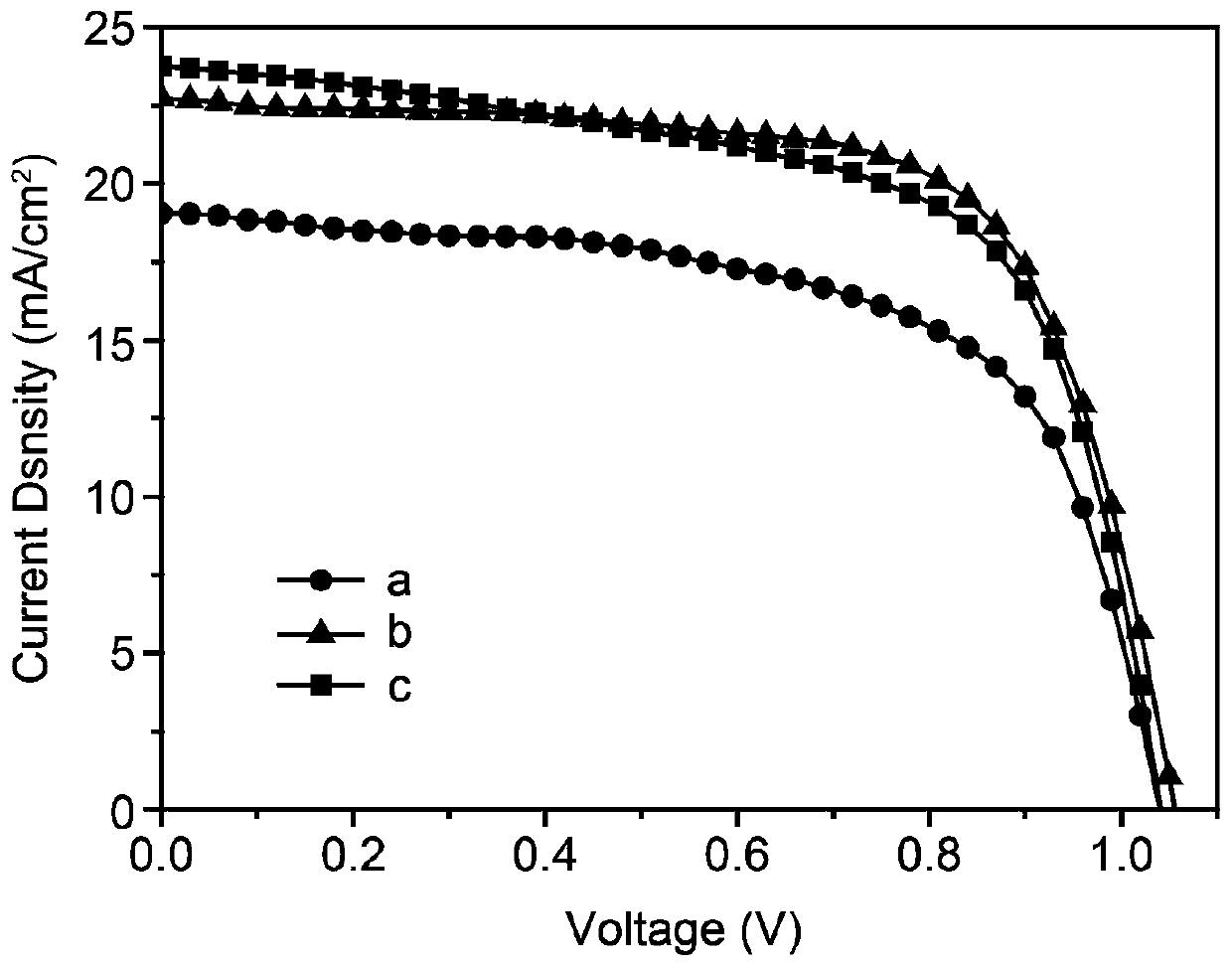

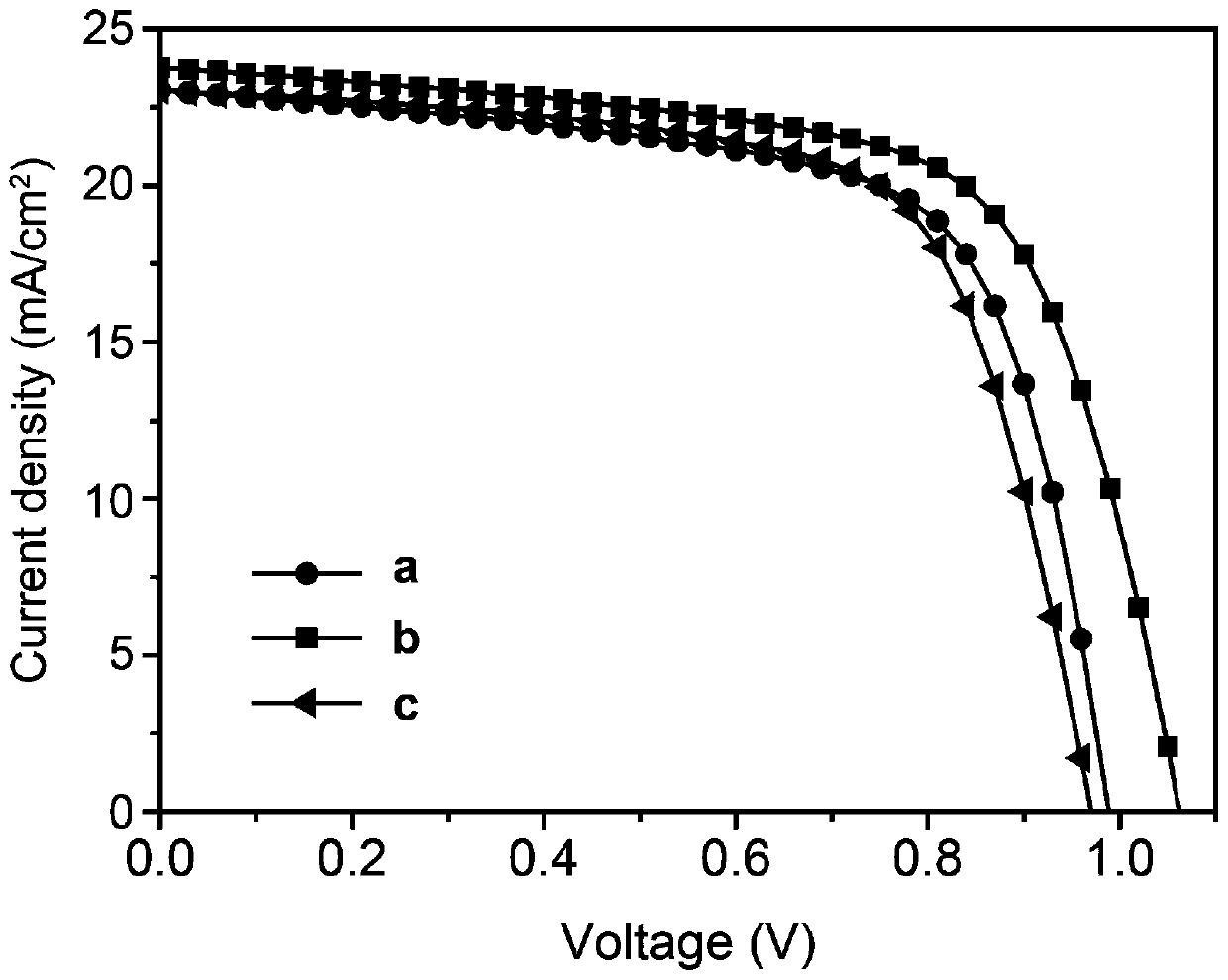

Embodiment 1

[0030] PbI 2 and CH 3 NH 3 I is dissolved in N,N-dimethylformamide (DMF) and dimethyl sulfoxide (DMSO) solution in a molar ratio of 1:1, the volume ratio of the two solvents is 10:1, and the mixed solution is heated at 60°C Stir evenly at high temperature for 2 hours to produce CH with a concentration of 1.25mol / L 3 NH 3 PB 3 solution, ready to use. Vanadium triisopropoxide (C 9 h 21 o 4 V) Dissolve in isopropanol (IPA) at a volume ratio of 1:300, stir the mixed solution at room temperature for 30 min, then mix it with PEDOT:PSS at a volume ratio of 1:2, and stir the mixed solution at room temperature 30min, prepared PEDOT:PSS and C 9 h 21 o 4 V-IPA blended solution, ready to use. Disperse PCBM in chlorobenzene to a concentration of 6 mg / mL and 20 mg / mL, and stir at room temperature for 24 hours to obtain a PCBM solution for use.

[0031] Sonicate the etched ITO conductive glass twice for 15 minutes with the lotion solution, deionized water, acetone, and ethano

Embodiment 2

[0034] PbI 2 and CH 3 NH 3 I is dissolved in N,N-dimethylformamide (DMF) and dimethyl sulfoxide (DMSO) solution in a molar ratio of 1:1, the volume ratio of the two solvents is 10:1, and the mixed solution is heated at 60°C Stir evenly at high temperature for 2 hours to produce CH with a concentration of 1.25mol / L 3 NH 3 PB 3 solution, ready to use. Vanadium triisopropoxide (C 9 h 21 o 4 V) Dissolve in isopropanol (IPA) at a volume ratio of 1:300, and stir the mixed solution at room temperature for 30 minutes, then mix it with PEDOT:PSS at a volume ratio of 1:2, and stir the mixed solution at room temperature 30min, prepared PEDOT:PSS and C 9 h 21 o 4 V-IPA blended solution, ready to use. Disperse PCBM in chlorobenzene to a concentration of 6 mg / mL and 20 mg / mL, and stir at room temperature for 24 hours to obtain a PCBM solution for use.

[0035] Sonicate the etched ITO conductive glass twice for 15 minutes with the lotion solution, deionized water, acetone, an

Embodiment 3

[0038] PbI 2 and CH 3 NH 3 I is dissolved in N,N-dimethylformamide (DMF) and dimethyl sulfoxide (DMSO) solution in a molar ratio of 1:1, the volume ratio of the two solvents is 10:1, and the mixed solution is heated at 60°C Stir evenly at high temperature for 2 hours to produce CH with a concentration of 1.25mol / L 3 NH 3 PB 3 solution, ready to use. Vanadium triisopropoxide (C 9 h 21 o 4 V) Dissolve in isopropanol (IPA) at a volume ratio of 1:300, stir the mixed solution at room temperature for 30 min, then mix it with PEDOT:PSS at a volume ratio of 1:2, and stir the mixed solution at room temperature 30min, prepared PEDOT:PSS and C 9 h 21 o 4 V-IPA blended solution, ready to use. Disperse PCBM in chlorobenzene to a concentration of 6 mg / mL and 20 mg / mL, and stir at room temperature for 24 hours to obtain a PCBM solution for use.

[0039] Sonicate the etched ITO conductive glass twice for 15 minutes with the lotion solution, deionized water, acetone, and ethano

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap