Diode rectifier production system

A diode rectification and production system technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as low production efficiency and quality, labor, consumption of more human resources, etc., to achieve high production efficiency and savings. Human resources, the effect of improving product yield and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solution of the present invention will be described in further non-limiting detail below in combination with preferred embodiments and accompanying drawings.

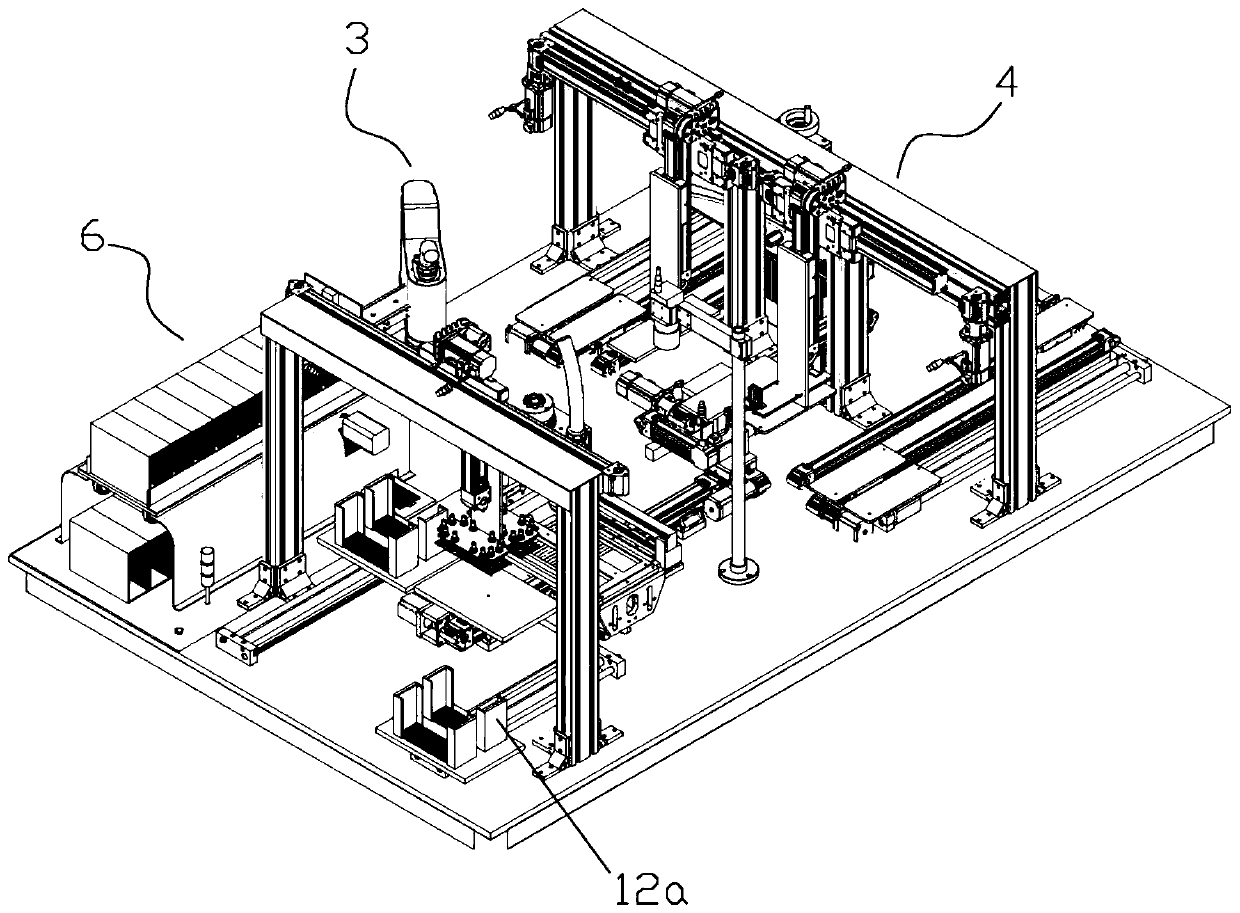

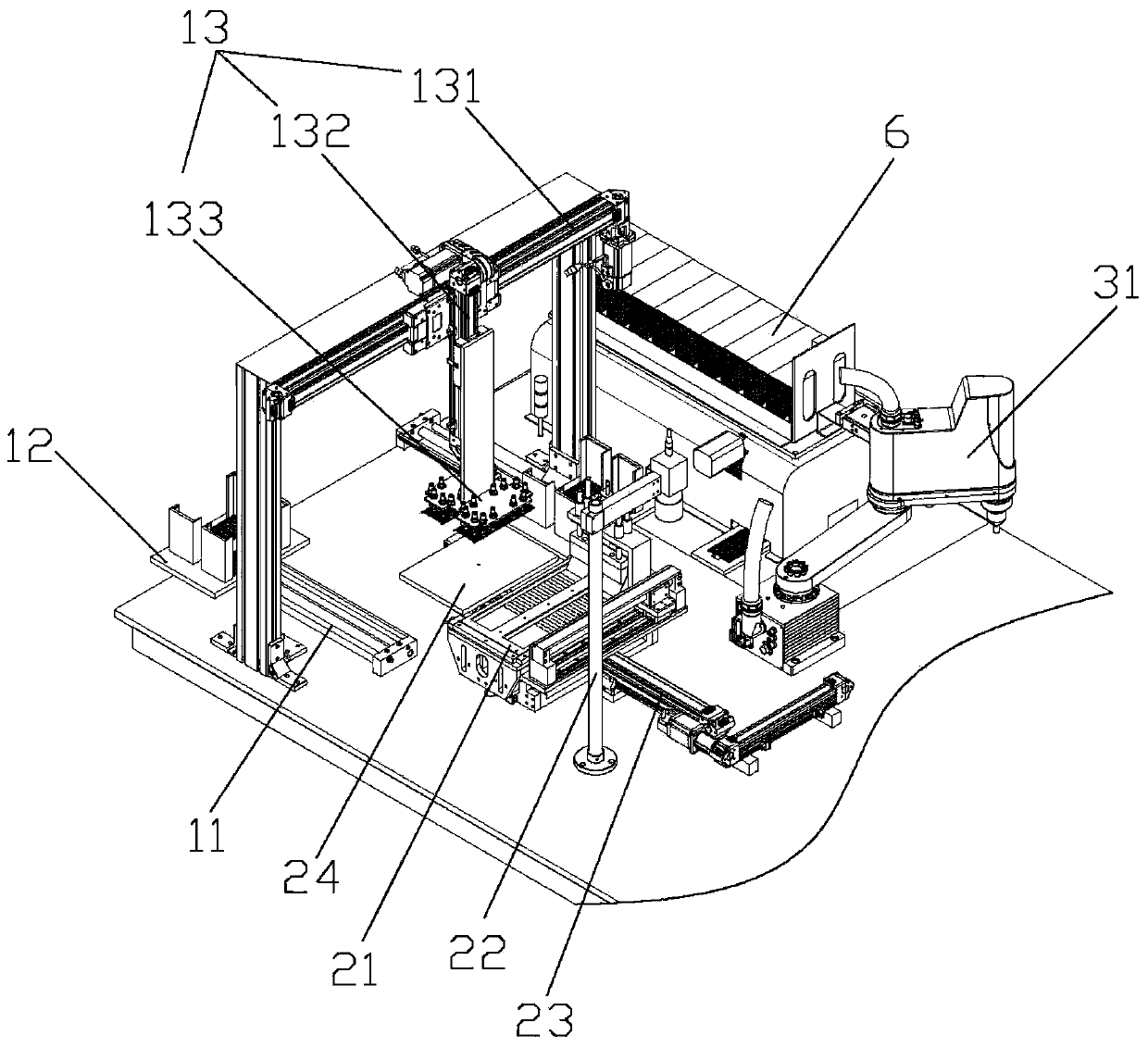

[0026] A kind of diode rectifier device production system, diode rectifier device comprises frame and is welded on frame and is crystal grain, and frame comprises upper frame 71 and lower frame 72 (such as Figure 6 and Figure 7 shown), before the production of the diode rectifier device starts, the upper frame 71 and the lower frame 72 are stored in the placing frame 12a (as figure 2 shown), the crystal grains are stored in the grain shaking plate 73 (as Figure 8 shown).

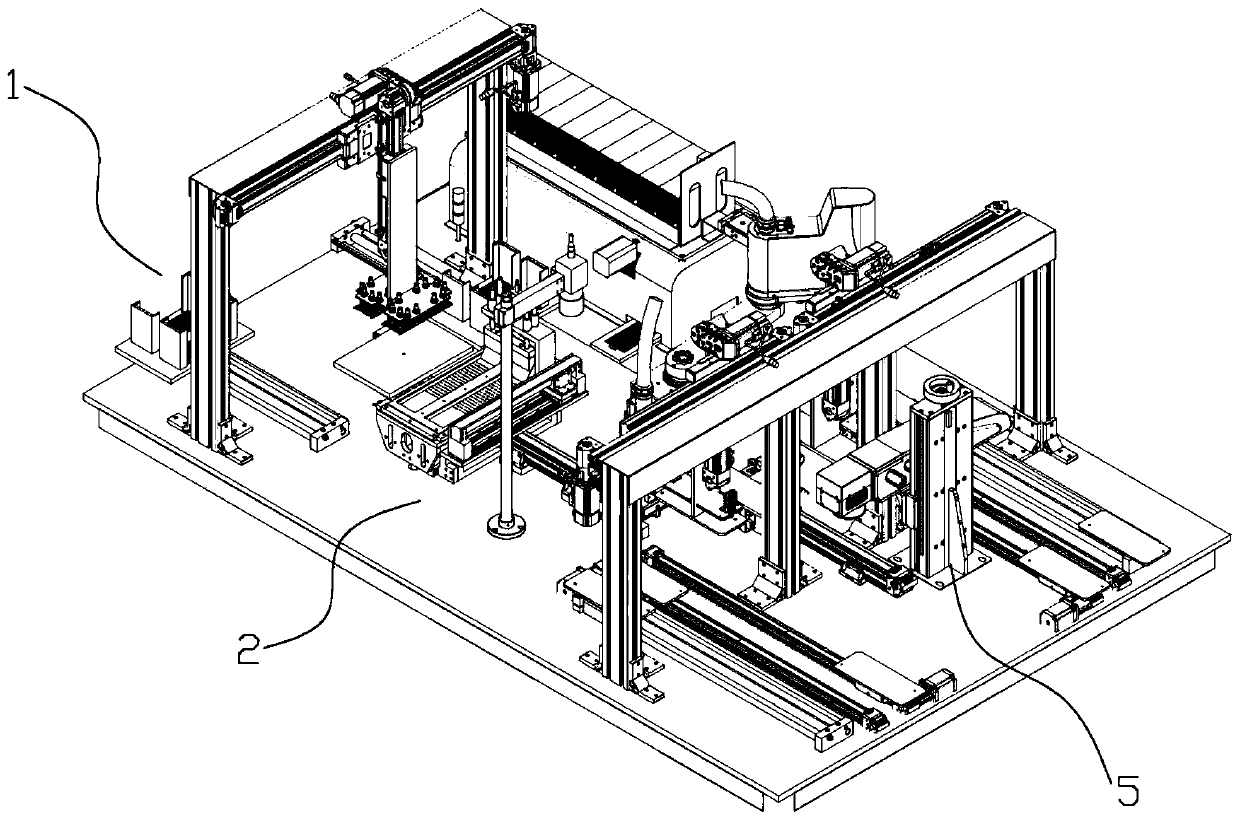

[0027] like figure 1 and figure 2 As shown, the diode rectifier device production system includes a feeding unit 1 for feeding the frame, a welding unit 5 for welding the frame, a printing unit 2 connected to the feeding unit 1 for printing solder paste on the frame, A fixing unit 4 connected to the soldering unit 5 for fix

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap