Lead-free solder paste with mixed solder powders for high temperature applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

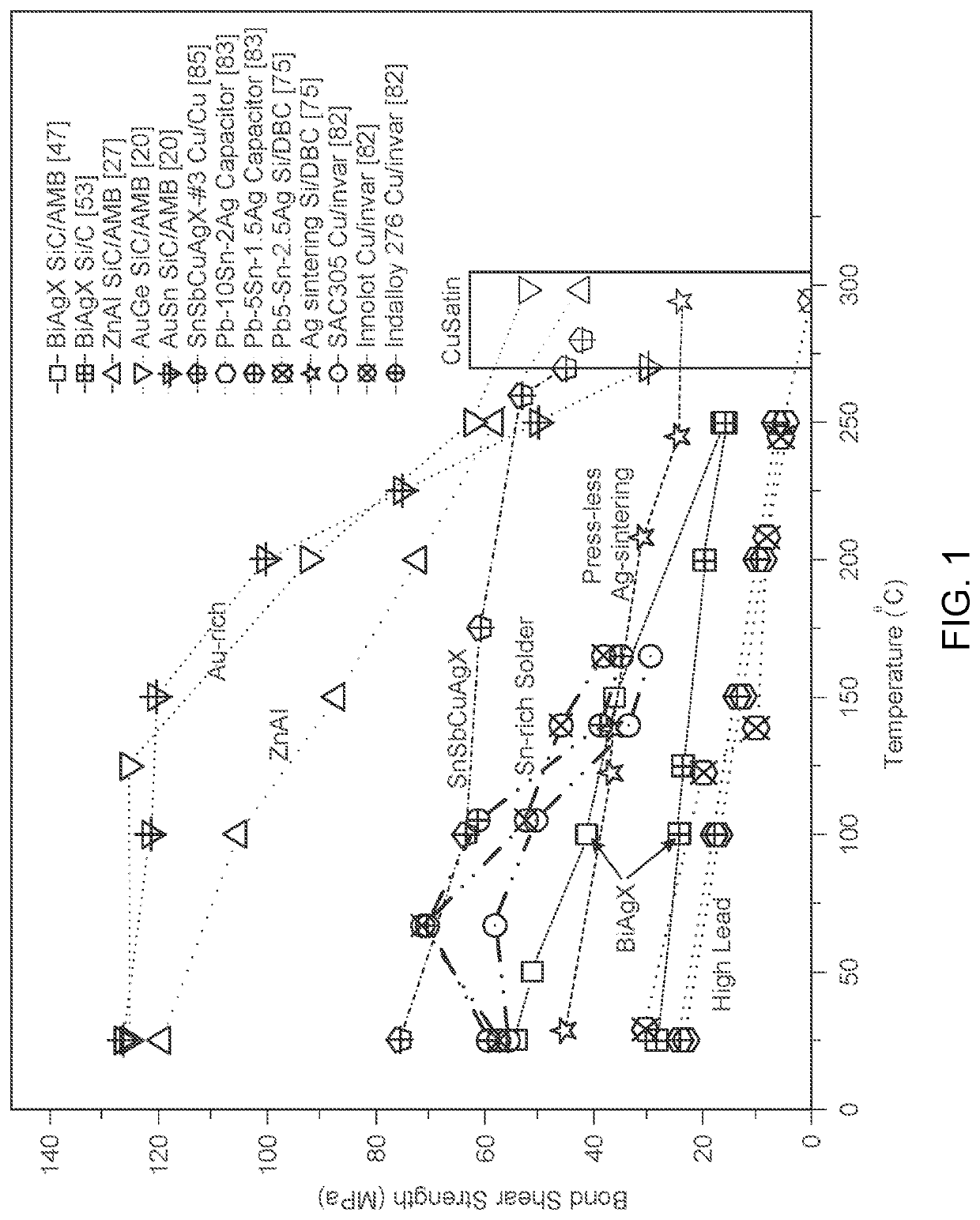

[0025]In order to be compatible with solder reflow profiles used in the electronics industry, some important characteristics of high temperature solders may include: (i) a solidus temperature of around 260° C. and above (in accordance with typical SMT solder reflow profiles), (ii) good thermal fatigue resistance, (iii) high thermal / electric conductivity, and / or (iv) low cost. To date, solders with a high lead content still dominate die-attachment applications in the power discrete market.

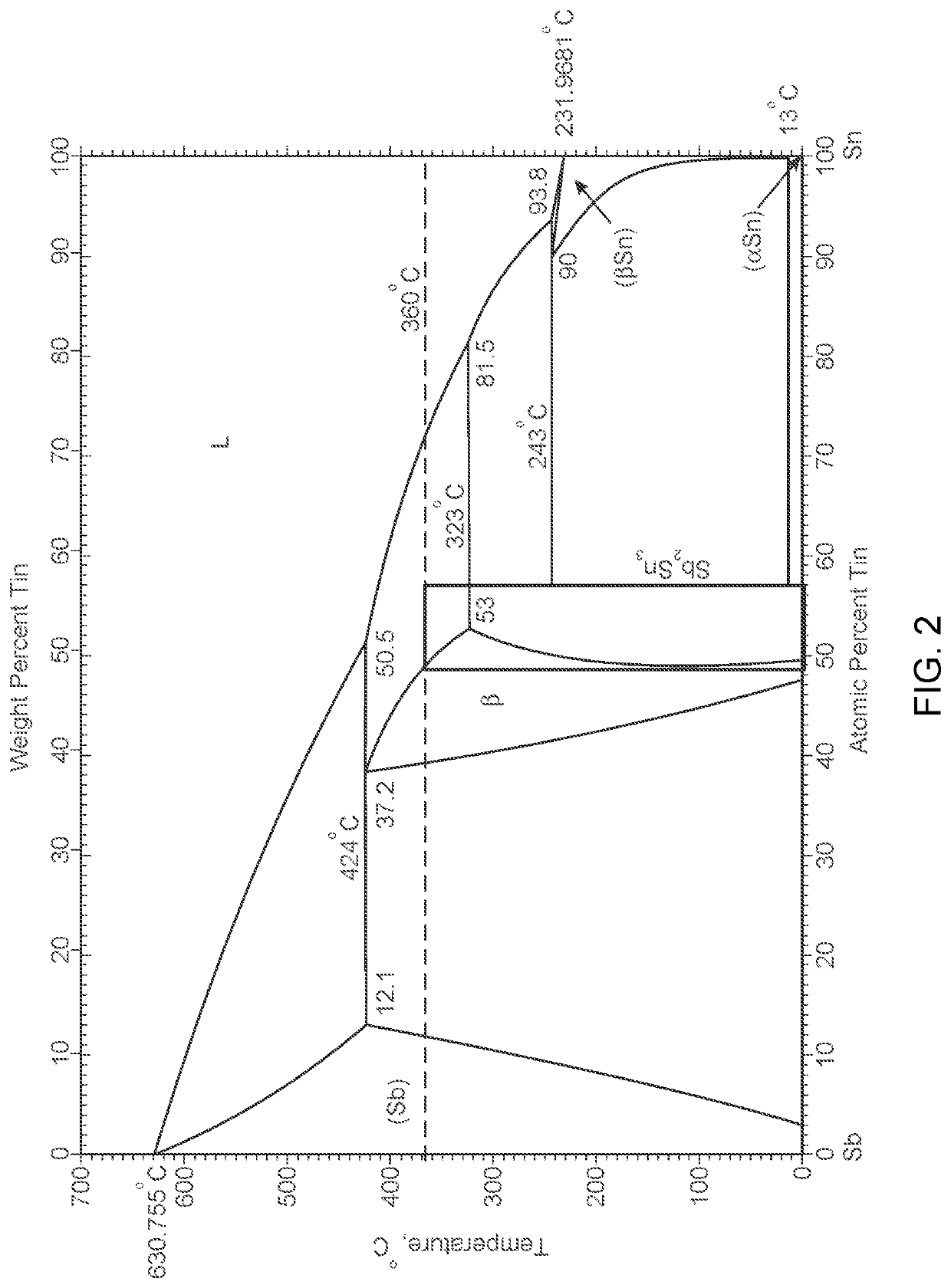

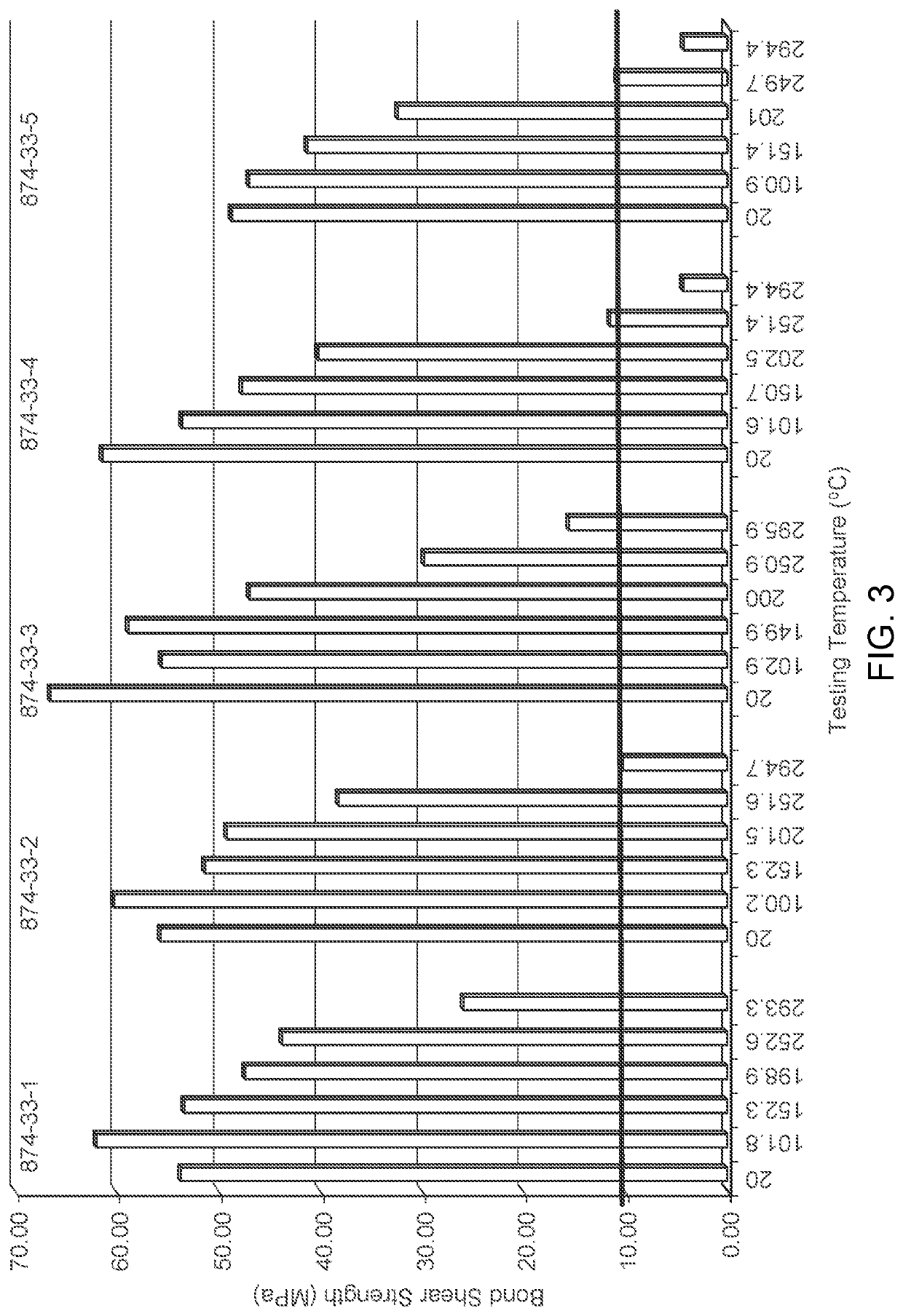

[0026]Implementations of the disclosure are directed to a lead-free solder paste with mixed solder powders that is particularly suitable for high temperature soldering applications involving multiple board-level reflow operations. The solder paste comprises two solder powders and flux. One of the solder powders has a substantially higher melting temperature than the other solder powder. For example, one of the solder powders may have a solidus temperature of a first solder alloy that is from 300 to

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap