Adjustable abnormal-shaped hard connecting hydraulic pipeline suitable for narrow space

A technology for hydraulic pipelines and narrow spaces, which is applied in the field of adjustable special-shaped hard-connected hydraulic pipelines. It can solve the problems of high oil leakage, poor heat dissipation, poor sealing, etc., and achieves reduced pipeline pressure loss, convenient production and assembly, and Effect of pipe length reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with accompanying drawing:

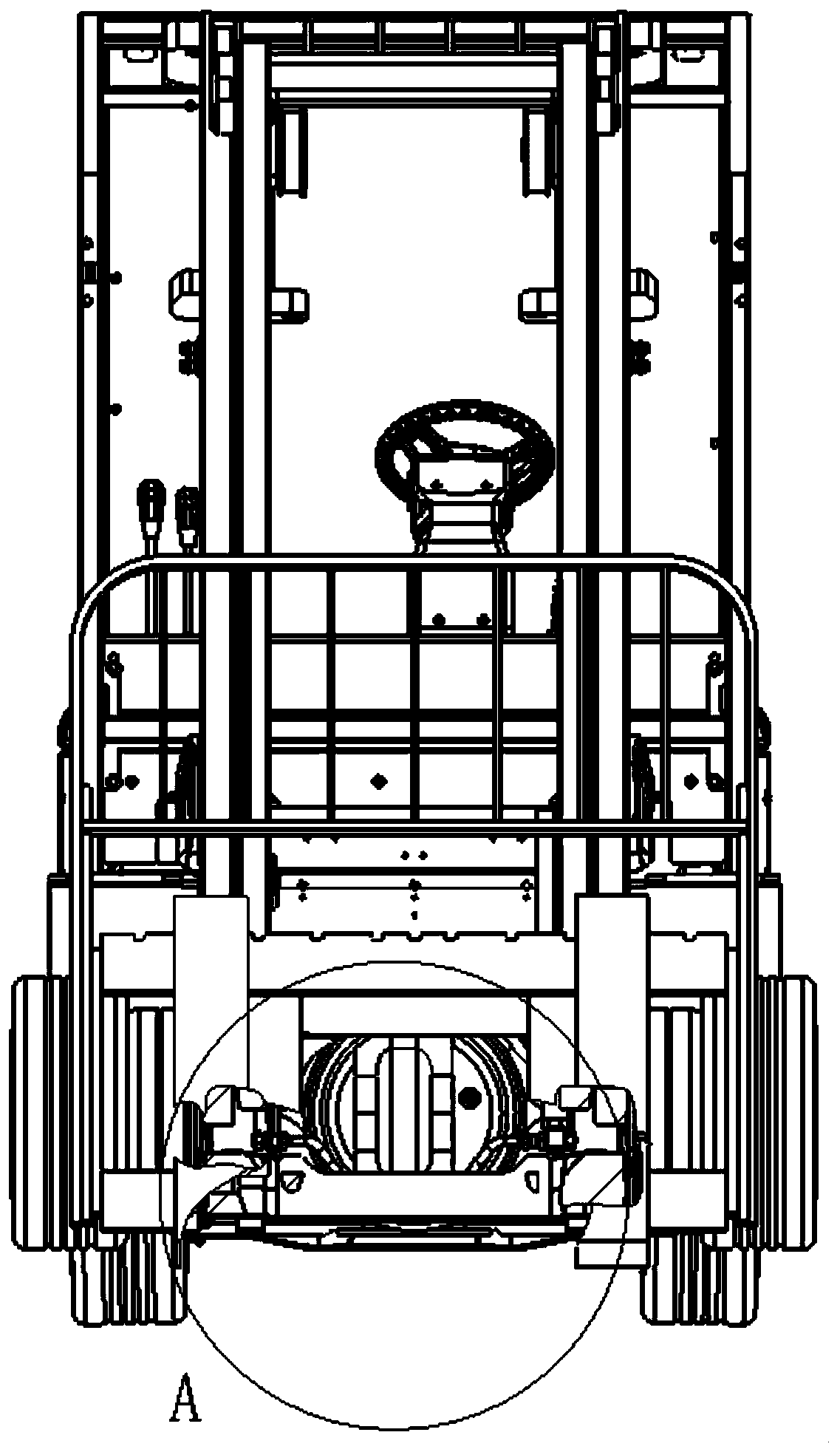

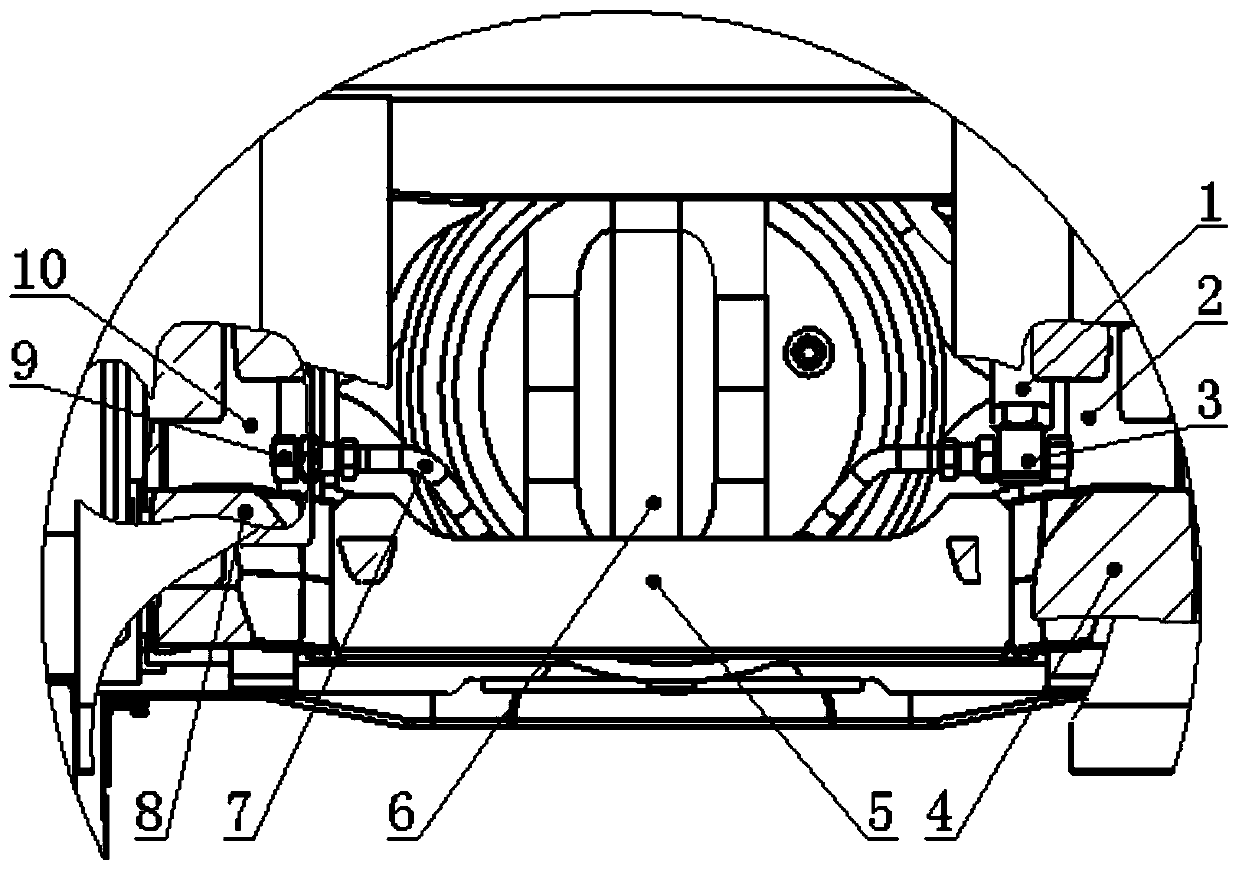

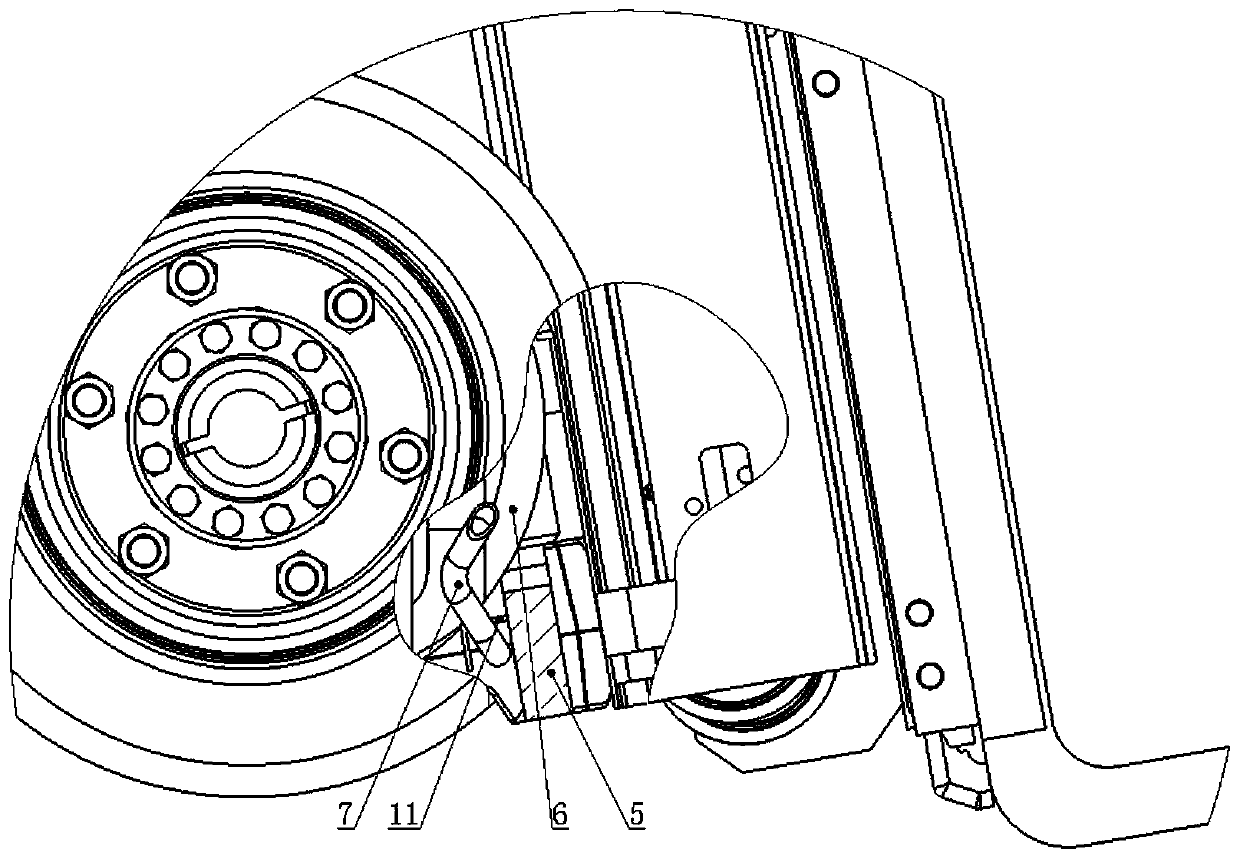

[0019] like Figure 1-7 The shown adjustable special-shaped hard-connected hydraulic pipeline suitable for narrow spaces includes a special-shaped high-pressure steel pipe assembly 7 arranged in the space formed between the outer mast beam 5 and the bottom of the axle housing bulge 6. The special-shaped high-pressure The steel pipe assembly 7 is bent and arranged along the outer contour of the axle housing bulge 6, and is close to the inside of the outer mast beam 5. The two ends of the special-shaped high-pressure steel pipe assembly 7 are horizontally bent and arranged, and the special-shaped high-pressure steel pipe assembly 7 is about The vertical central axis of the pipe body is symmetrically arranged, and the middle part of the special-shaped high-pressure steel pipe assembly 7 is concave-convex and bent along the outer contour of the axle housing bulge 6 to avoid the co

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap