Special equipment with deburring function for yoke machining

A special equipment and deburring technology, which is applied in the direction of metal processing equipment, manufacturing tools, metal processing, etc., can solve the problems of inability to clamp the shape of the horn joint, low integration, and weak clamping, etc., to achieve adjustment and Easy and fast effect of positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

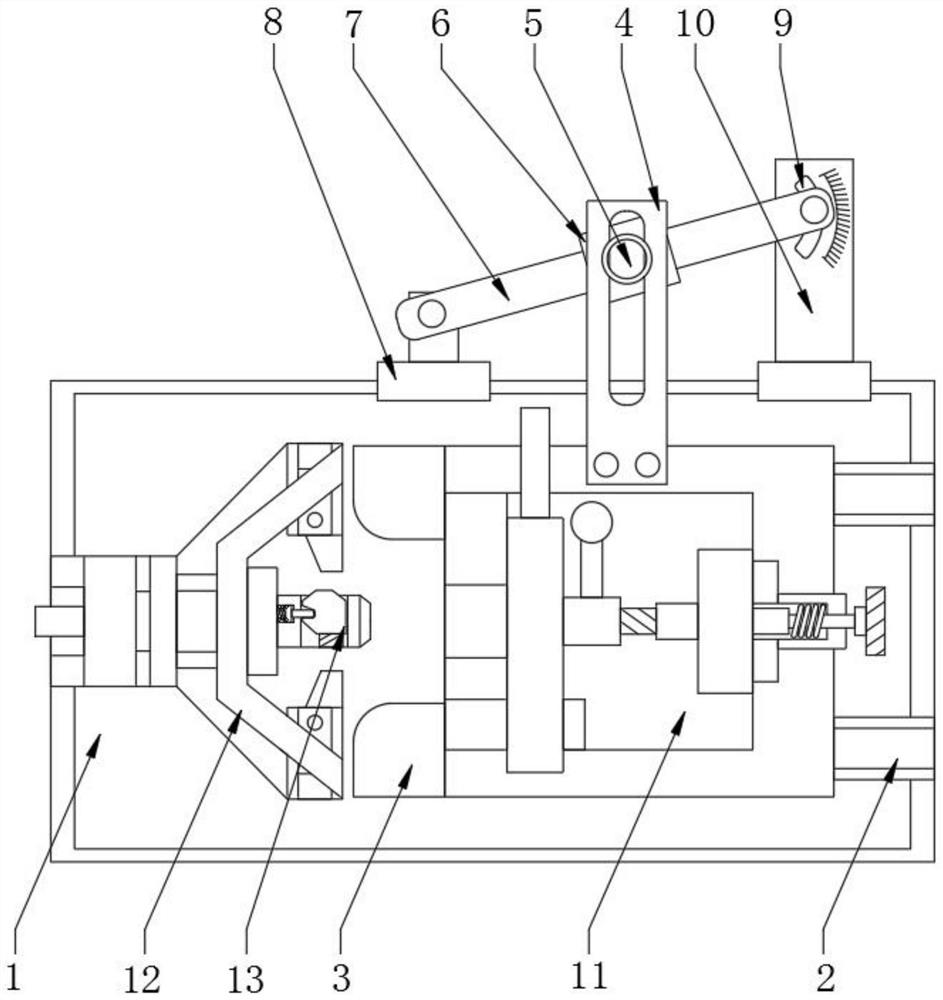

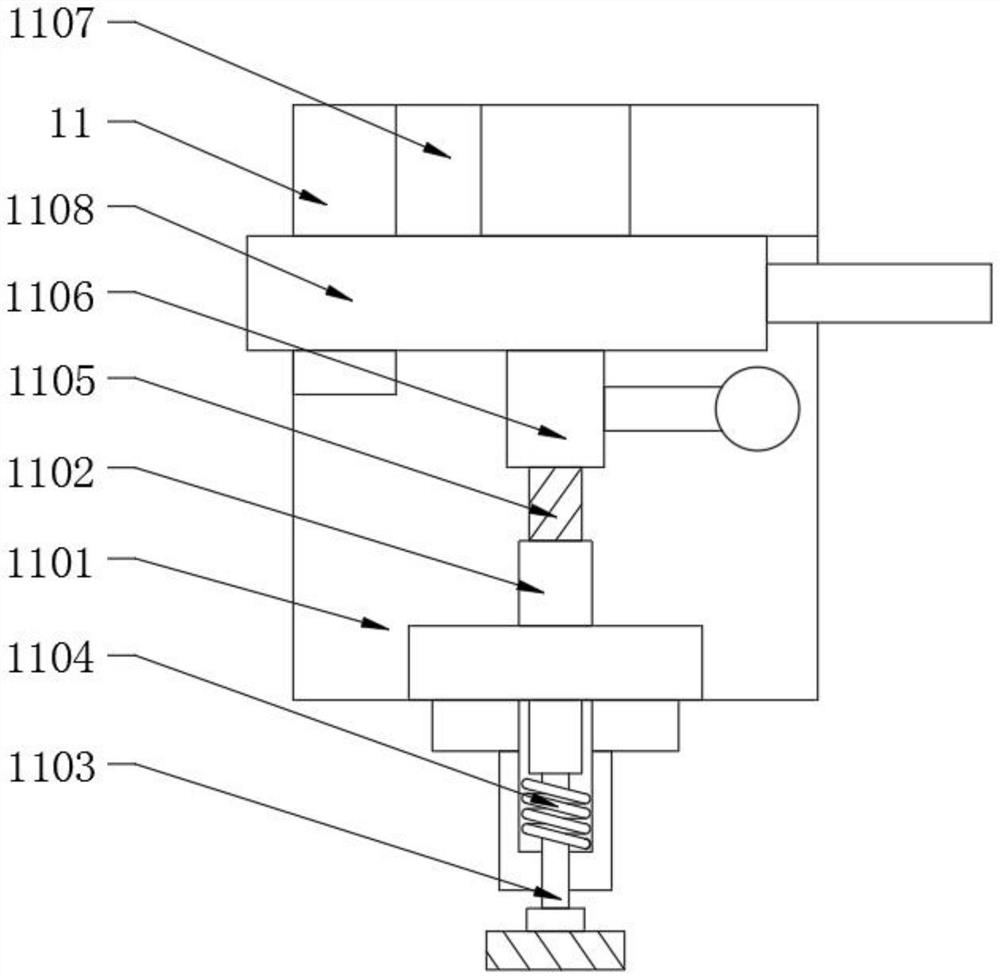

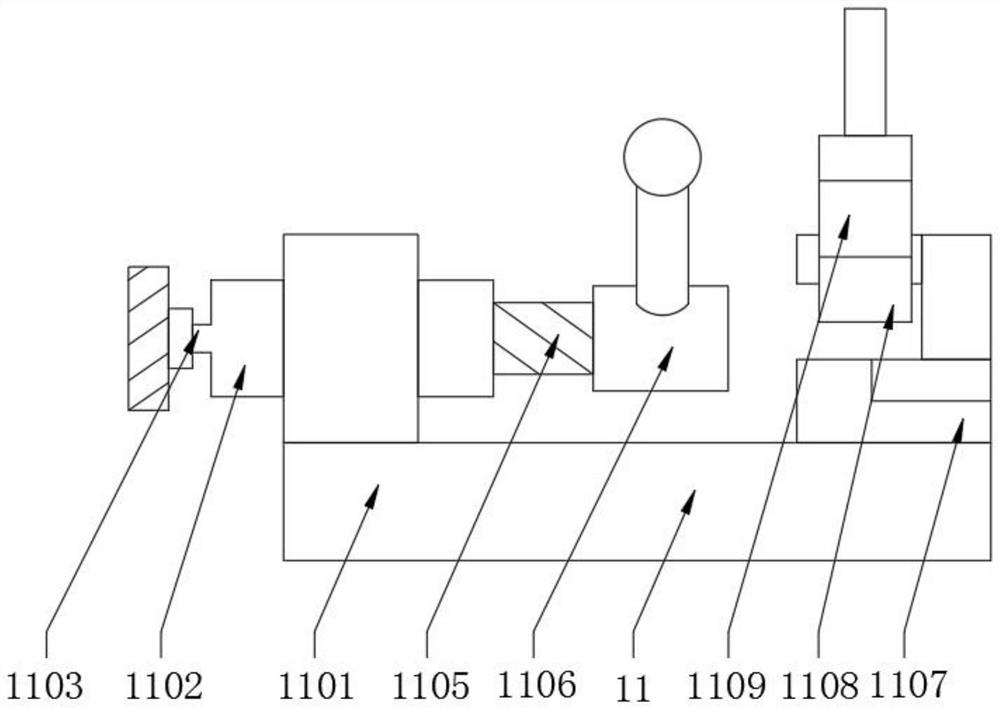

[0027] see figure 1 , The present invention provides a technical solution: a special equipment with deburring for yoke processing, a slide rail 2 is provided on the right side of the top of the bottom plate 1, and a slide table 3 is slidably installed on the top of the slide rail 2, and the top of the slide table 3 is provided with There is a wing plate 4, and a straight groove 5 is formed through the middle of the front of the wing plate 4. The back of the straight groove 5 is rotatably installed with a slider 6, and the base 1101 is connected to the slider 6 through the wing plate 4, and the slider 6 A rocker 7 is provided through sliding inside, the left input end of the rocker 7 is rotated and provided with a left end plate 8, and the right back of the rocker 7 is provided with a scale groove 9, the outside of the scale groove 9 is provided with a right end plate 10, and the left end plate 8 The right end plate 10 is symmetrically and fixedly installed on both sides of the to

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap