Three-coordinate measuring device for measuring wall thickness of vertex of wave crest of thin-wall special-shaped tube and measuring method of measuring device

A technology of three-coordinate measurement and special-shaped tubes, which is applied in the field of mechanical processing, can solve the problems of difficult measurement of the wall thickness of the peak and apex, and achieve the effects of easy industrialization and application, simple manufacturing process, and reduced operation difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

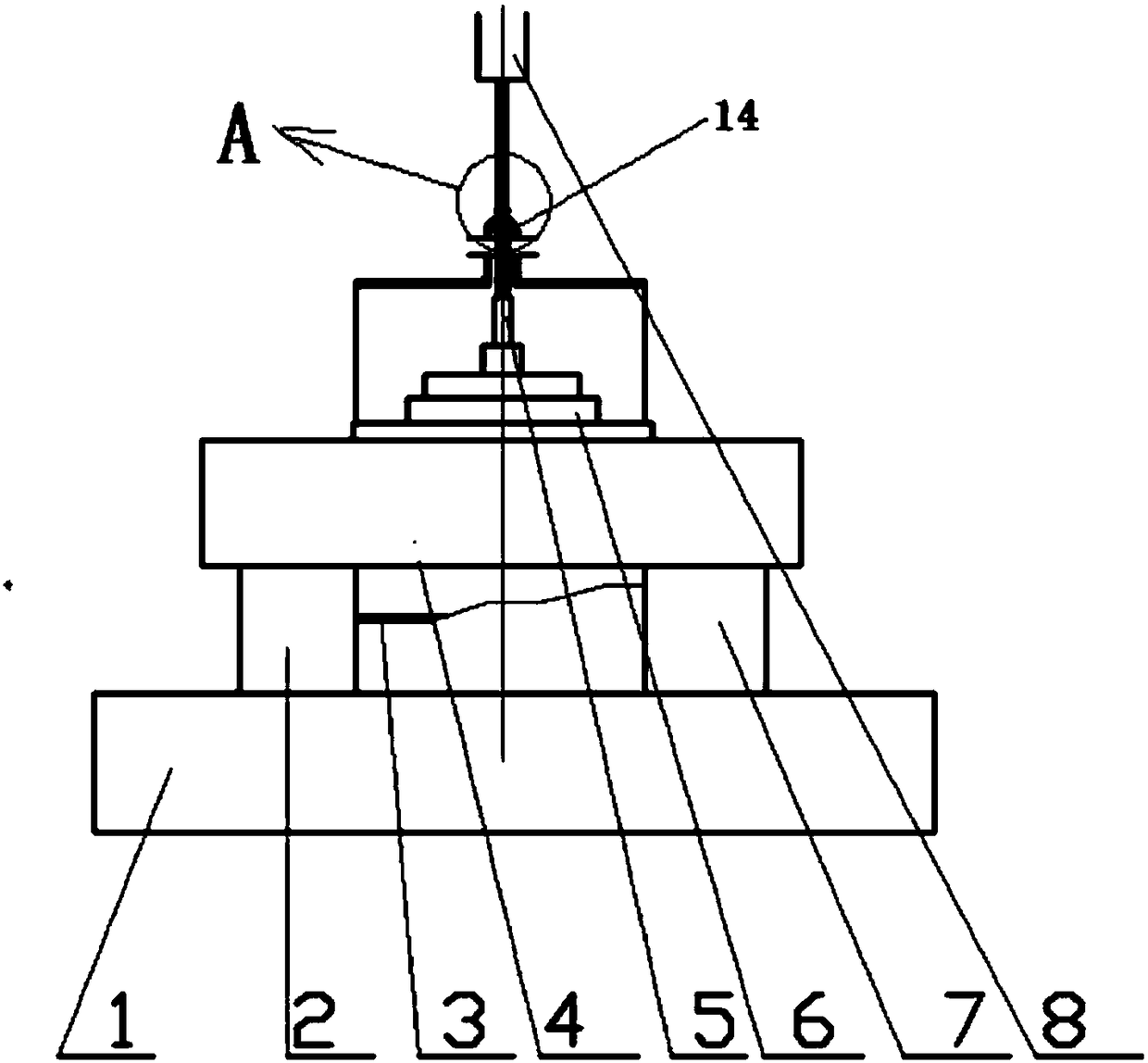

[0047] A three-coordinate measuring device for measuring the wall thickness of the crest apex of a thin-wall special-shaped pipe, comprising:

[0048] Three-coordinate measuring workbench 1, the top is fixedly provided with the first equal-height block 2 and the second equal-height block 7 with the same height; three-coordinate measuring head 8, which is used to measure the object to be measured; moving mechanism, which makes the above-mentioned three-coordinate movement of the measuring head; a control device which controls the above-mentioned movement mechanism;

[0049] Thin-wall special-shaped tube positioning mechanism, including,

[0050] The support beam body 4 is used to pass through the lumen of the thin-walled special-shaped tube 3;

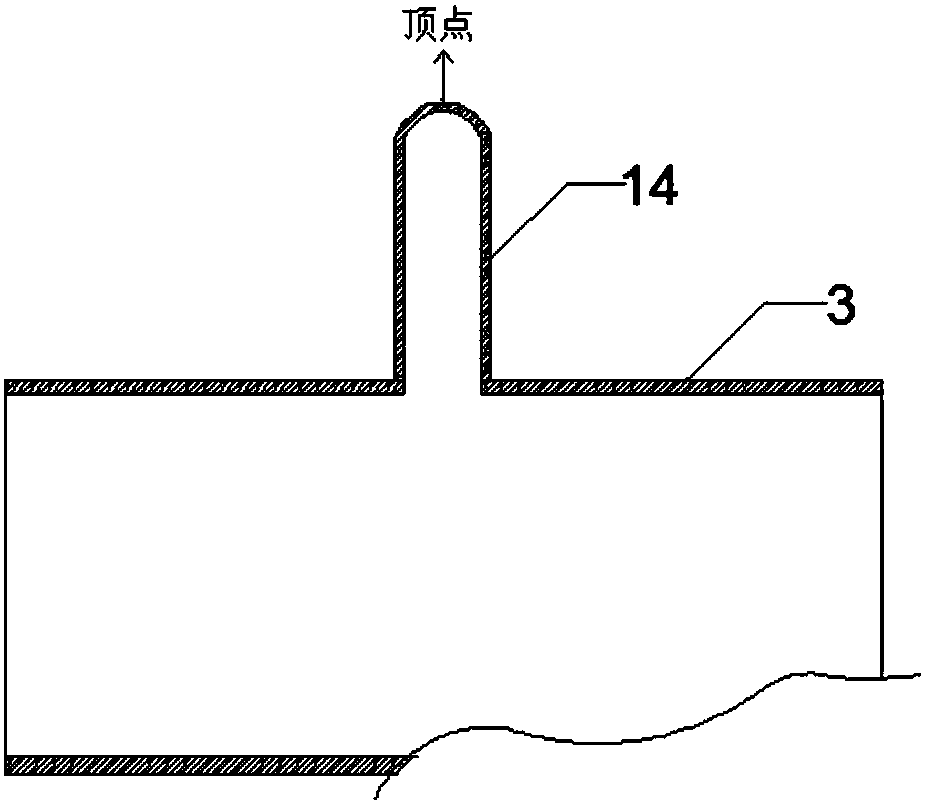

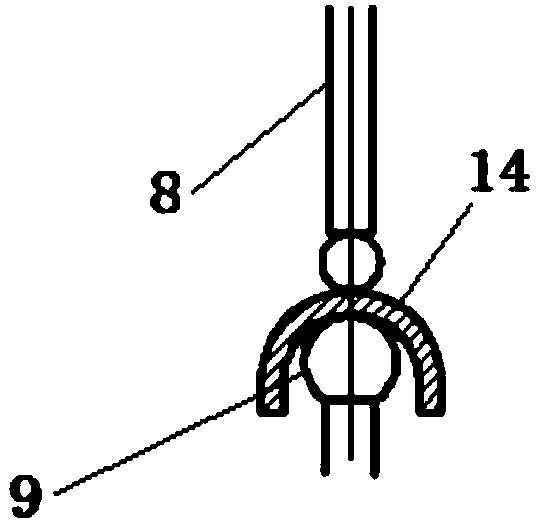

[0051] Inner support positioning rod 5: the bottom end is positioned on the support beam body 4 through the fixing seat 6, and the outer diameter of the inner support positioning rod 5 is smaller than the inner diameter of the crest 14 in

Embodiment 2

[0064] This embodiment is further optimized on the basis of Embodiment 1. The first equal-height block 2 and the second equal-height block 7 are both V-shaped blocks 15, and the upper and lower sides of the V-shaped block are all provided with V surfaces. 16.

[0065] As a preferred mode, the parallelism of the upper and lower surfaces of the V-shaped block is 0.005mm, the flatness is 0.005mm, the parallelism of the left and right surfaces is 0.005mm, and the flatness is 0.005mm. The first equal-height block 2 and the second equal-height block 7 can be standard V-shaped blocks, and the standard V-shaped blocks should meet the JB / T8047-95 standard.

Embodiment 3

[0067] The measuring method of the three-coordinate measuring device for measuring the wall thickness of the crest apex of the thin-walled special-shaped pipe comprises the following steps:

[0068] Step 1, positioning: clamp the bottom end of the inner support positioning rod 5 on the fixing seat 6, and place the fixing seat 6 on the top of the supporting beam body 4;

[0069] Step 2, the support beam body 4 passes through the lumen of the thin-walled special-shaped tube 3, and the two ends are placed on the first equal-height block 2 and the second equal-height block 7, and the thin-walled special-shaped tube 3 is placed obliquely so that the support The top of the supporting part is taken as the measurement point, and the coordinate X of the first point is measured by the three-coordinate three-coordinate probe 8 0 Y 0 Z 0 ;

[0070] Step 3: keep the position of the positioning mechanism of the thin-walled special-shaped tube unchanged, and put the thin-walled special-shape

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap