Environment-friendly exterior wall coating and construction process thereof

An exterior wall coating and environmental protection technology, applied in the direction of epoxy resin coating, anti-corrosion coating, coating, etc., can solve the problems of adhesion, water resistance and aging resistance, inconsistent temperature and building impact, etc., to increase the anti-corrosion Corrosion ability, improve adhesion, reduce the effect of harm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

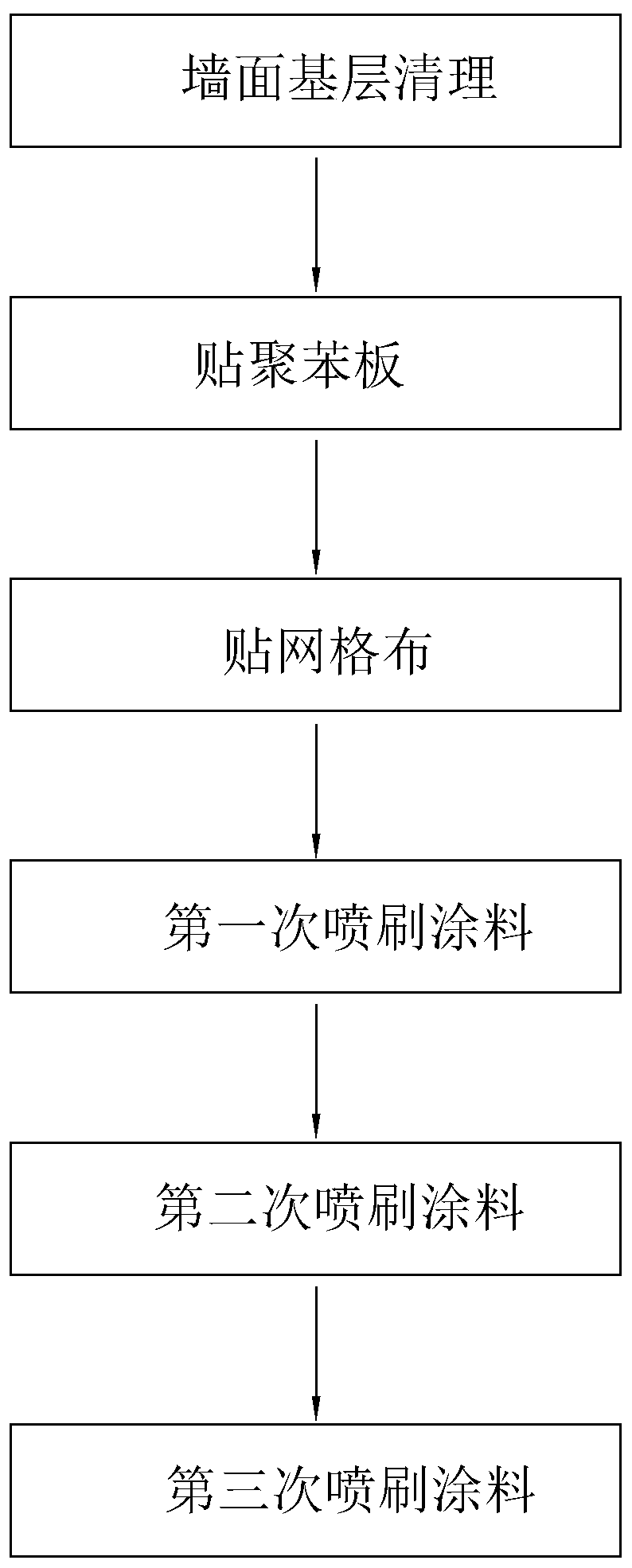

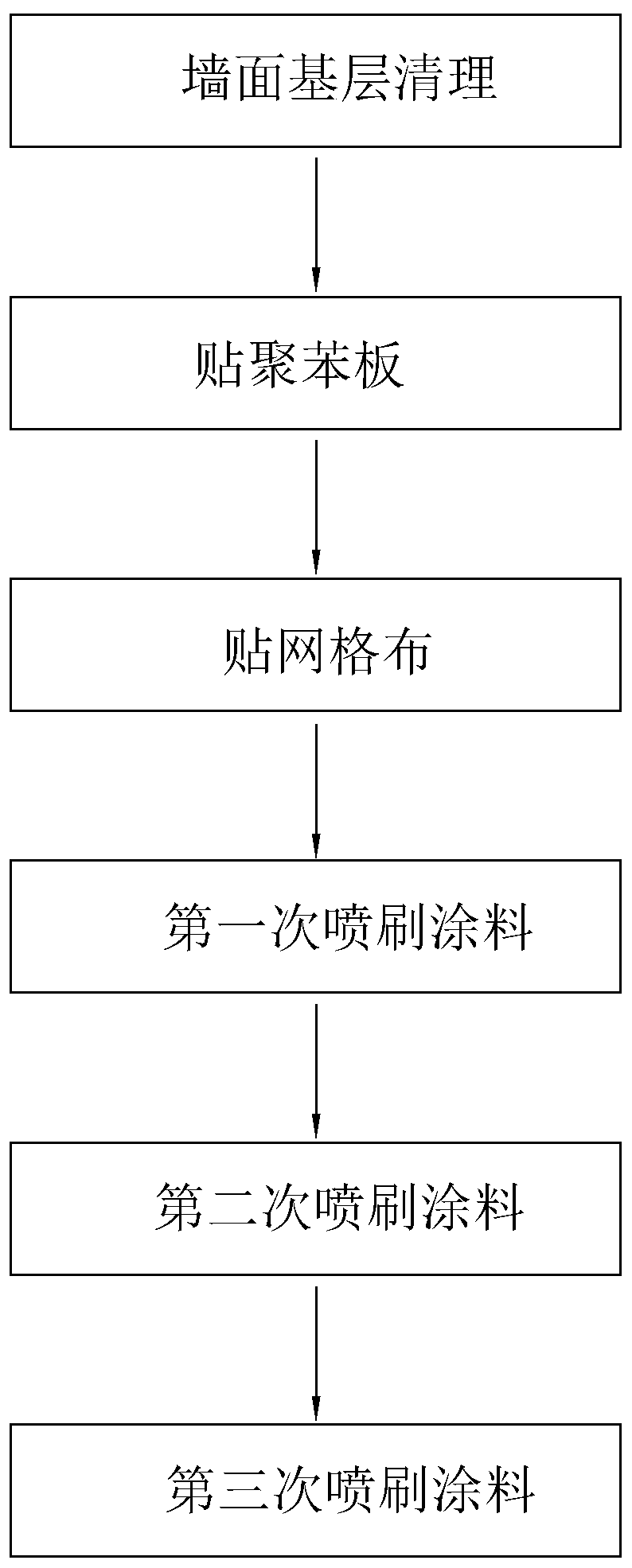

Method used

Image

Examples

Example Embodiment

[0035] Example 1

[0036] An environmentally-friendly exterior wall paint, in parts by weight, the raw materials include 35 parts of styrene-acrylic emulsion, 15 parts of epoxy resin, 15 parts of polyvinyl alcohol, 5 parts of silane coupling agent, 12 parts of nano zinc oxide, and 2 parts of wollastonite powder Parts, 5 parts of water, 6 parts of titanium dioxide, 1.1 parts of curing agent, 1.2 parts of defoaming agent, 8 parts of carboxymethyl cellulose, 4 parts of activated carbon, 1.2 parts of sodium lignosulfonate; the curing agent is polyisocyanate, defoaming The agent is polydimethylsiloxane.

Example Embodiment

[0037] Example 2

[0038] An environmentally-friendly exterior wall paint, in parts by weight, the raw materials include 45 parts of styrene acrylic emulsion, 20 parts of epoxy resin, 20 parts of polyvinyl alcohol, 10 parts of silane coupling agent, 16 parts of nano zinc oxide, and 4 parts of wollastonite powder Parts, 8 parts of water, 9 parts of titanium dioxide, 1.4 parts of curing agent, 1.4 parts of defoaming agent, 12 parts of carboxymethyl cellulose, 7 parts of activated carbon, 1.7 parts of sodium lignosulfonate; among them, the curing agent adopts polyisocyanate, defoaming The agent is polydimethylsiloxane.

Example Embodiment

[0039] Example 3

[0040] An environmentally-friendly exterior wall paint, in parts by weight, the raw materials include 55 parts of styrene-acrylic emulsion, 25 parts of epoxy resin, 25 parts of polyvinyl alcohol, 15 parts of silane coupling agent, 20 parts of nano zinc oxide, and 6 parts of wollastonite powder. Parts, 10 parts of water, 12 parts of titanium dioxide, 1.7 parts of curing agent, 1.6 parts of defoaming agent, 16 parts of carboxymethyl cellulose, 10 parts of activated carbon, 2.2 parts of sodium lignosulfonate; the curing agent adopts polyisocyanate, defoaming The agent is polydimethylsiloxane.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap