Device for efficiently producing nitrogen fertilizer synergist

A nitrogen fertilizer synergist and high-efficiency technology, applied in fertilization devices, mixers with rotary stirring devices, transportation and packaging, etc., can solve the problems of complex production process, low production efficiency, long time for finished products, etc., and reduce noise. The effect of pollution, improving production efficiency and saving production time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

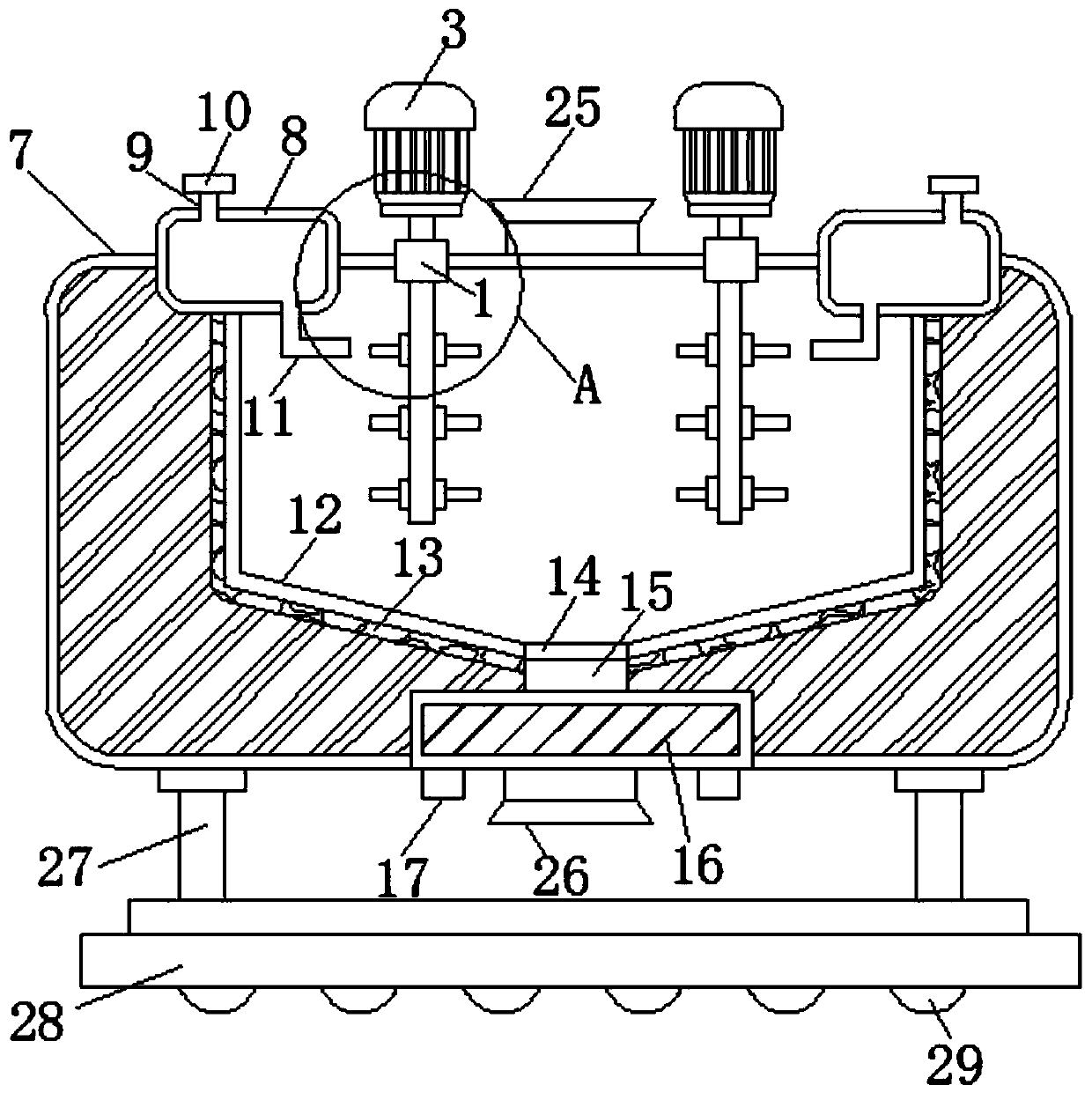

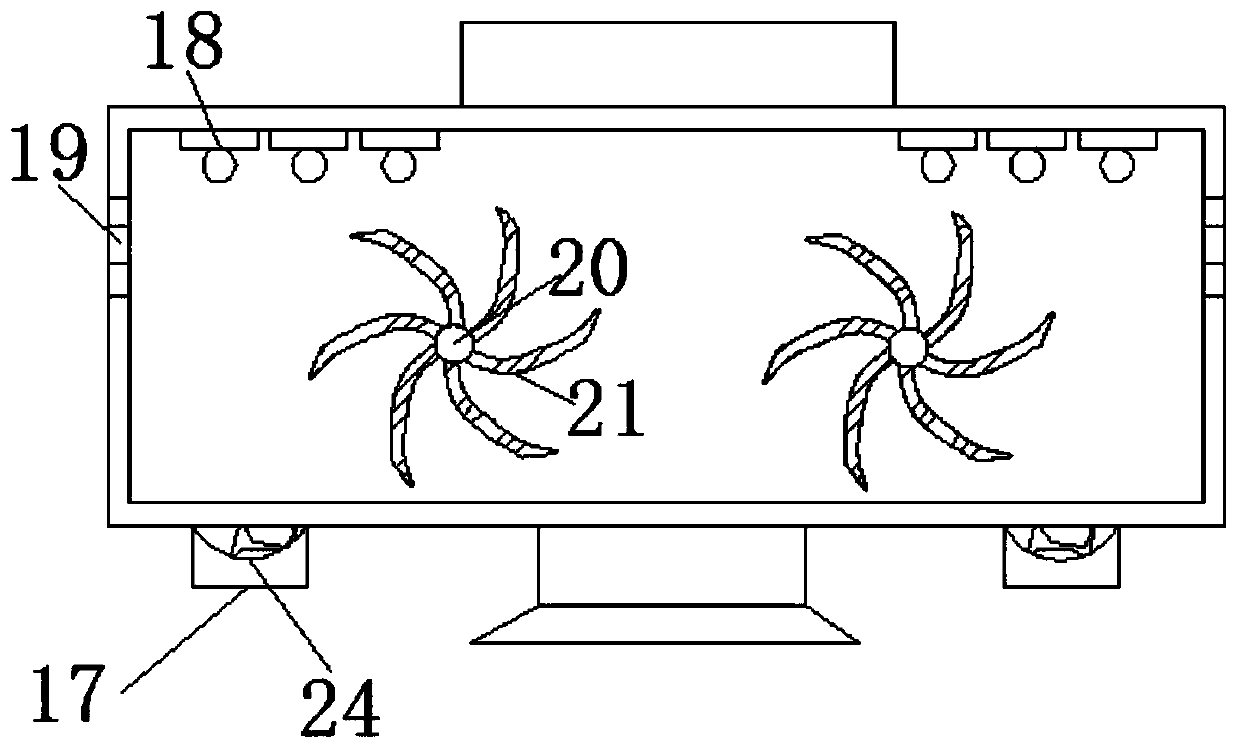

[0027] see Figure 1-4 , the present invention provides the following technical solutions: a device for efficiently producing nitrogen fertilizer synergists, comprising a first interlocking shaft 1, the upper surface of the first interlocking shaft 1 is fixedly connected with a first motor shaft 2, and the first motor shaft 2 The end far away from the first interlocking shaft 1 is fixedly connected with the first motor 3 , the end of the first interlocking shaft 1 away from the first motor shaft 2 is fixedly connected with the stirring shaft 4 , and the outer surface of the stirring shaft 4 is fixedly connected with a fixed block 5 , the outer surface of the fixed block 5 is fixedly connected with the stirring blade 6, the outer surface of the first interlocking shaft 1 is fixedly connected with the organic body 7, the inner surface of the body is fixedly installed with a water storage tank 8, and the upper surface of the water storage tank 8 is provided with The water inlet pipe

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap