Two-in-one gradual change mirror and preparation method thereof

A two-in-one, gradient hole technology, applied in the field of gradient mirrors, can solve the problems of high purchase cost, inconvenient carrying, troublesome operation, etc., and achieve the effect of reducing work intensity, reducing the number of lenses to be carried, and reducing purchase costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

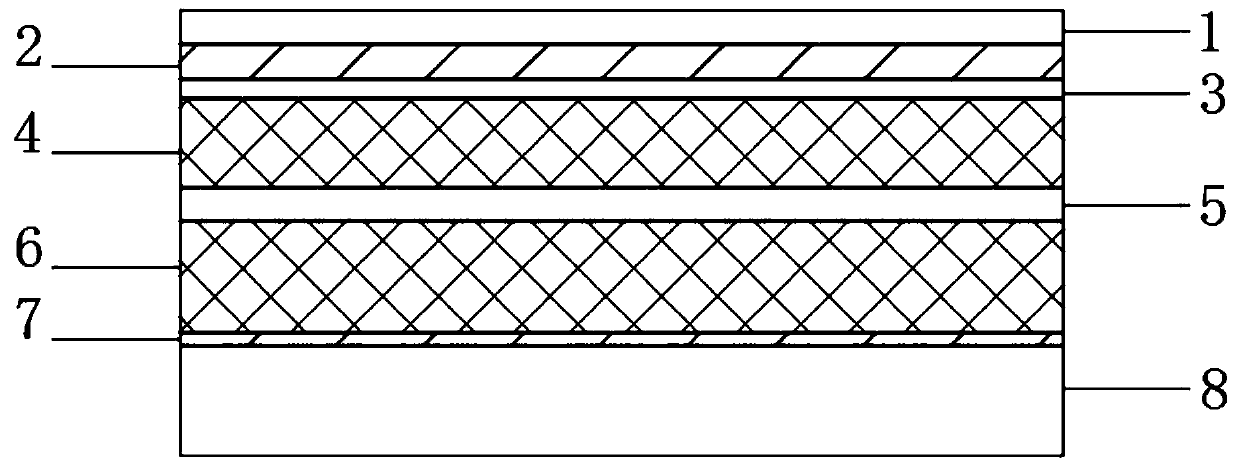

[0044] see figure 1 , two-in-one gradient mirror, including the lens body, the upper end of the lens body is provided with a coating layer, and the coating layer includes the first film layer 1, the second film layer 2, the third film layer 3, and the fourth film layer 4 from the inside to the outside. , the fifth film layer 5, the sixth film layer 6, the seventh film layer 7 and the eighth film layer 8, the first film layer 1 is Al 2 o 3 film layer, the second film layer 2 is Cr film layer, the third film layer 3 is H 4 film layer, the fourth film layer 4 is SiO 2 , the fifth film layer 5 is Ni film layer, the sixth film layer 6 is SiO 2 , the seventh film layer 7 is Cr, and the eighth film layer 8 is SV-55.

[0045] It should be pointed out that the material that produces the gradient film is mainly a metal material or a mixture of metal materials. In addition to the above-mentioned Cr film layer, the Ni film layer is considered to be Al, Ag, Ti, Au, Cu, Fe, Zn, Sn, Mo A f

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap