Localization coating for automobile tail gas purification catalyst, and preparation method thereof

A technology for purifying catalysts and automobile exhaust, which is applied in the field of automobile exhaust purification, can solve problems such as difficulty in popularization, and achieve the effect of reducing costs and improving durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

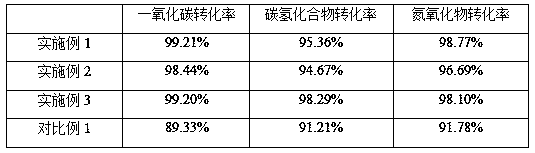

Embodiment 1

[0036] A localized coating of an automobile exhaust purification catalyst, which is coated on the inner wall of the honeycomb ceramic carrier channel arranged at the outlet end of the automobile engine. Catalytic conversion of harmful substances such as CO, HC and NOx in the exhaust gas into CO 2 、H 2 O and N 2 and other harmless gases into the atmosphere.

[0037] In this embodiment, the honeycomb ceramic carrier includes a front half area and a second half area with a height ratio of 1:2, the coating of the first half area includes an inner coating, a middle coating, and an outer coating in sequence, and the coating of the second half area sequentially includes Internal and external coatings. The inner and outer coatings of the first half area have the same components as the inner and outer coatings of the second half area.

[0038] According to parts by mass, the components of the inner coating include 64.5 parts of rare earth composite oxide, 26 parts of modified alumina,

Embodiment 2

[0050] In this embodiment, the honeycomb ceramic carrier includes a front half area and a second half area with a height ratio of 1:1. The coating in the first half area includes an inner coating, a middle coating, and an outer coating in sequence, and the coating in the second half area also sequentially Including inner coating, middle coating and outer coating, but the coating coating parts of the first half area and the second half area are different.

[0051] According to parts by mass, the components of the inner coating include 45.95 parts of rare earth composite oxide, 45.95 parts of modified alumina, 8 parts of additives and 0.1 part of noble metal. Among them, the rare earth composite oxide includes Ce1, which is composed of 90% of a mixture of ceria and zirconia in a mass ratio of 1:1 and 10% of lanthanum oxide. Modified alumina includes 90% alumina and 10% lanthanum oxide. Pd is selected as the precious metal. The auxiliary agent is a mixture of pseudo-boehmite and B

Embodiment 3

[0064] In this embodiment, the honeycomb ceramic carrier includes a front half area and a second half area with a height ratio of 1:4, the coating of the first half area includes an inner coating, a middle coating and an outer coating in sequence, and the coating of the second half area includes Internal and external coatings. The inner and outer coatings of the first half area have the same components as the inner and outer coatings of the second half area.

[0065] According to parts by mass, the components of the inner coating include 74.2 parts of rare earth composite oxide, 14.8 parts of modified alumina, 10 parts of additives and 1 part of noble metal. Among them, the rare earth composite oxide includes Ce1, which consists of 97% of a mixture of cerium oxide and zirconia with a mass ratio of 2:1 and 3% of yttrium oxide. Modified alumina includes 99.9% alumina and 0.1% lanthanum oxide. Pd is selected as the precious metal. The auxiliary agent is an equal mass ratio mixtur

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap