Vibrating feeding packaging scale

A technology of vibrating feeding and packaging scales, applied in packaging, packaging protection, transportation and packaging, etc., can solve problems such as low weighing accuracy and uneven feeding, and achieve improved weighing accuracy, uniform and fast feeding, and guaranteed neat effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0019] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, rather than all the embodiments.

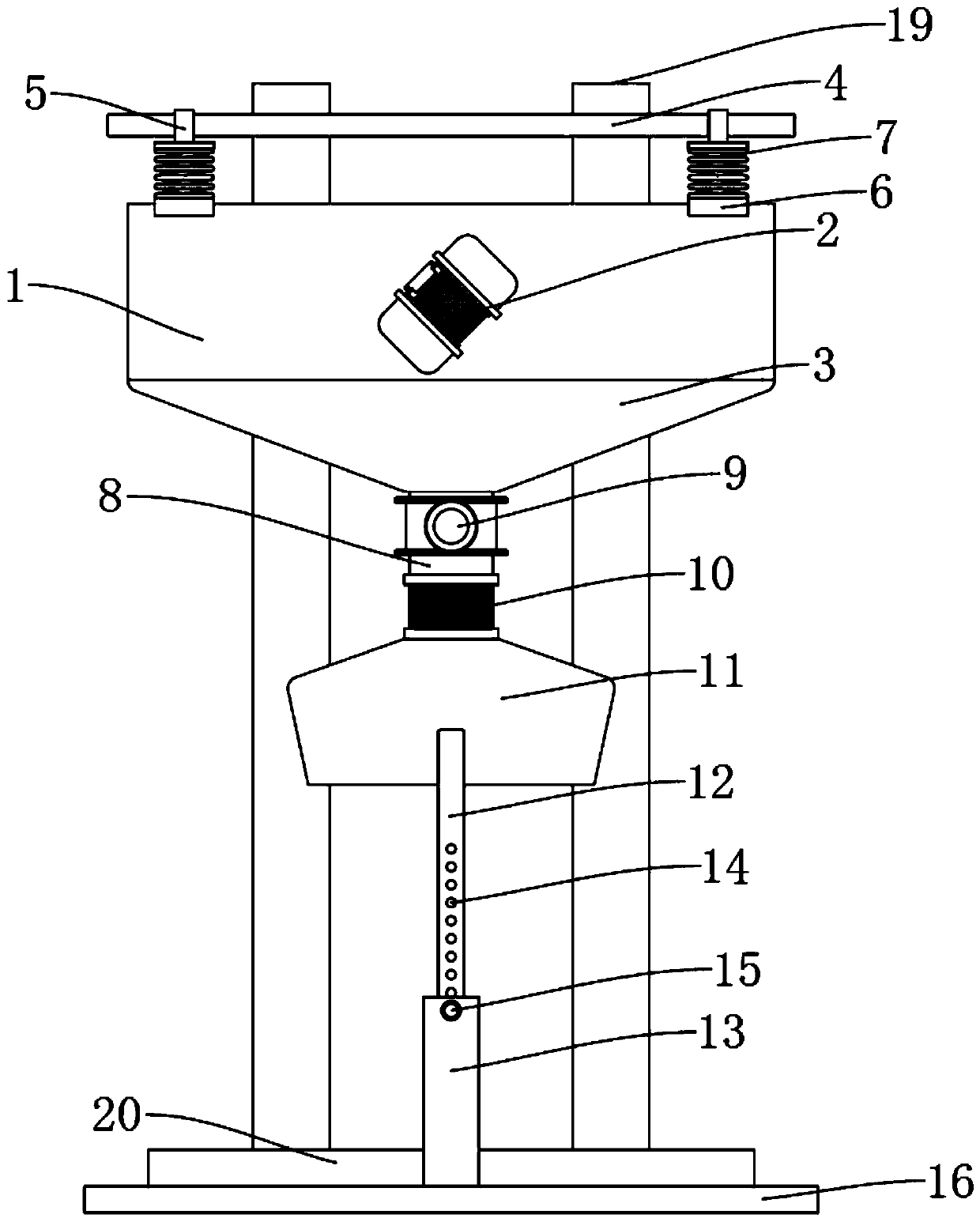

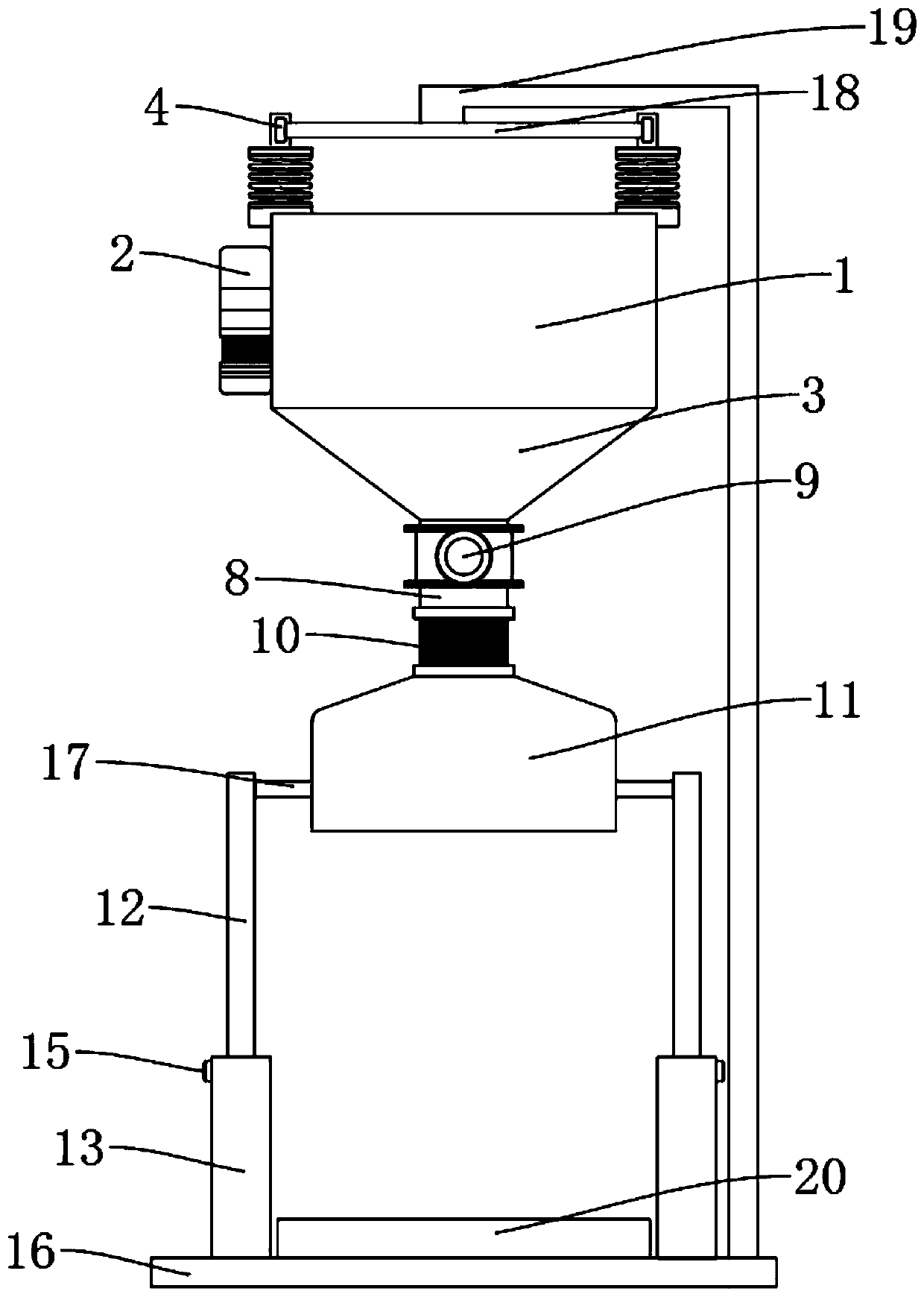

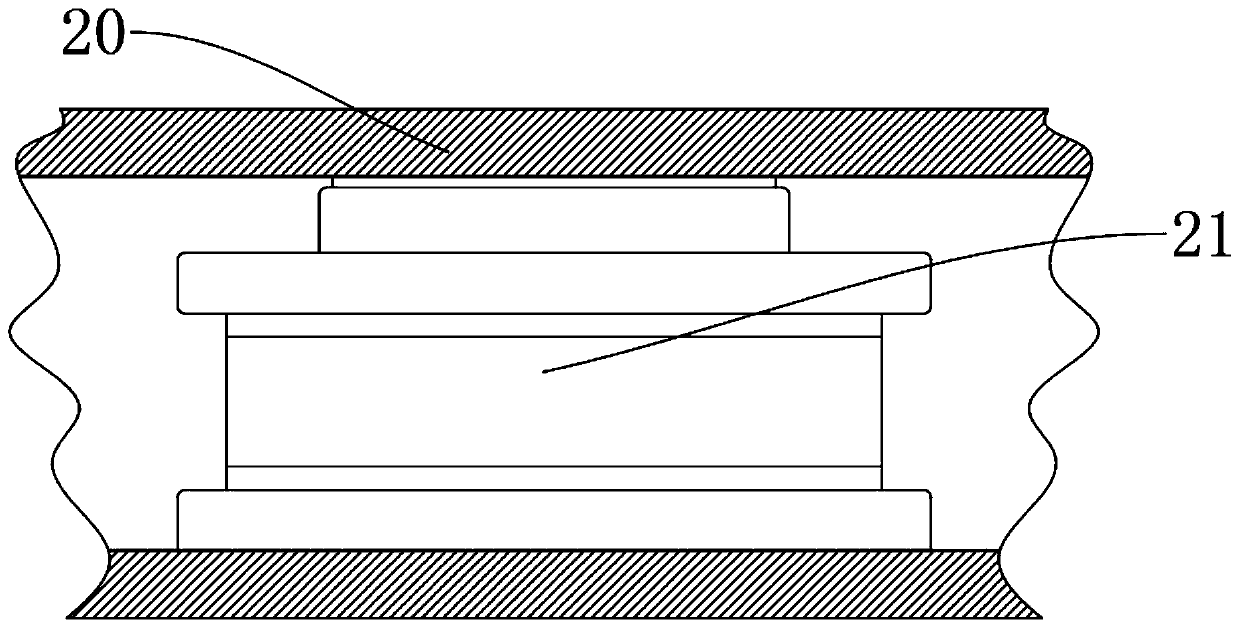

[0020] See Figure 1-3 , An embodiment provided by the present invention: a vibration feeding packaging scale, comprising a feeding box 1, a vibration motor 2 is installed at the front end of the feeding box 1, and the vibration motor 2 and the feeding box 1 are connected by screws, A guide trough 3 is installed at the lower end of the feed box 1, and the guide trough 3 is welded to the feed box 1. The top and rear ends of the feed box 1 are equipped with ejector rods 4, and between the two ejector rods 4 are installed The top plate 18 is connected, and the top plate 18 is welded to the top rod 4, the first fixing blocks 5 are installed on bot

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap