Water-resistant PVA film and preparation method thereof

A film and inner layer technology, applied in the field of water-resistant PVA film and its preparation, can solve the problems of not utilizing the relevant mechanical properties of PVA, and achieve the effect of reducing thickness and high water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] A water-resistant PVA film, the front and back surfaces of the water-resistant PVA film are coated with two layers of RTV, which are respectively an inner layer RTV and an outer layer RTV.

[0069] Wherein the inner layer RTV belongs to the RTV of the deacetate type, and is made by the following components in parts by mass:

[0070]

[0071] 0.05 parts of tert-butyl titanate;

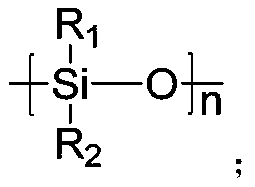

[0072] Among them, the Among them, n is 10 and is terminated with a hydroxyl group.

[0073] Wherein the outer layer RTV belongs to the RTV of the acetone-removing type, and is made from the following components in parts by mass:

[0074]

[0075] 0.2 parts of dibutyltin diacetate;

[0076] Among them, the Among them, n is 100, and it is terminated with a hydroxyl group.

[0077] The preparation method of the above-mentioned water-resistant PVA film may further comprise the steps:

[0078] (1) Coupling agent formula is coated on the PVA film surface, and described coupling agent formul

Embodiment 2

[0089] A water-resistant PVA film, the front and back surfaces of the water-resistant PVA film are coated with two layers of RTV, which are respectively an inner layer RTV and an outer layer RTV.

[0090] Wherein the inner layer RTV belongs to the RTV of the dealcoholization type, and is made from the following components in parts by mass:

[0091]

[0092] 0.2 parts of dibutyltin dilaurate;

[0093] Among them, the n is 100 and is terminated with a hydroxyl group.

[0094] Wherein the outer layer RTV belongs to the RTV of the deketoxime type, and is made from the following components in parts by mass:

[0095]

[0096] 0.2 parts of dibutyltin dilaurate;

[0097] Among them, the Among them, n is 100, and it is terminated with a hydroxyl group.

[0098] The preparation method of the above-mentioned water-resistant PVA film may further comprise the steps:

[0099] (1) Coupling agent formula is coated on the PVA film surface, and described coupling agent formula has fo

Embodiment 3

[0110] A water-resistant PVA film, the front and back surfaces of the water-resistant PVA film are coated with two layers of RTV, which are respectively an inner layer RTV and an outer layer RTV.

[0111] Wherein the inner layer RTV belongs to the RTV of the deketoxime type, and is made from the following components in parts by mass:

[0112]

[0113] 0.1 part of dibutyltin dilaurate;

[0114] Among them, the Among them, n is 50 and is terminated with a hydroxyl group.

[0115] Wherein the outer layer RTV belongs to the RTV of the acetone-removing type, and is made from the following components in parts by mass:

[0116]

[0117] 0.1 part of dibutyltin diacetate;

[0118] Among them, the Among them, n is 70, and is terminated with a hydroxyl group.

[0119] The preparation method of the above-mentioned water-resistant PVA film may further comprise the steps:

[0120] (1) Coupling agent formula is coated on the PVA film surface, and described coupling agent formula h

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap