Vertical stirring, grinding and pyrolysis device

A pyrolysis, vertical technology, applied in the directions of dissolution, transportation and packaging, special forms of dry distillation, etc., can solve the problems of rapid heat and effective supply restricting the application of biomass rapid pyrolysis and liquefaction technology, and achieve direct rapid pyrolysis and liquefaction, Enhance the heat and mass transfer rate and the effect of rapid pyrolysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0020] In order to make the objectives, technical solutions and advantages of the present invention clearer, the following further describes the present invention in detail with reference to the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, but not used to limit the present invention.

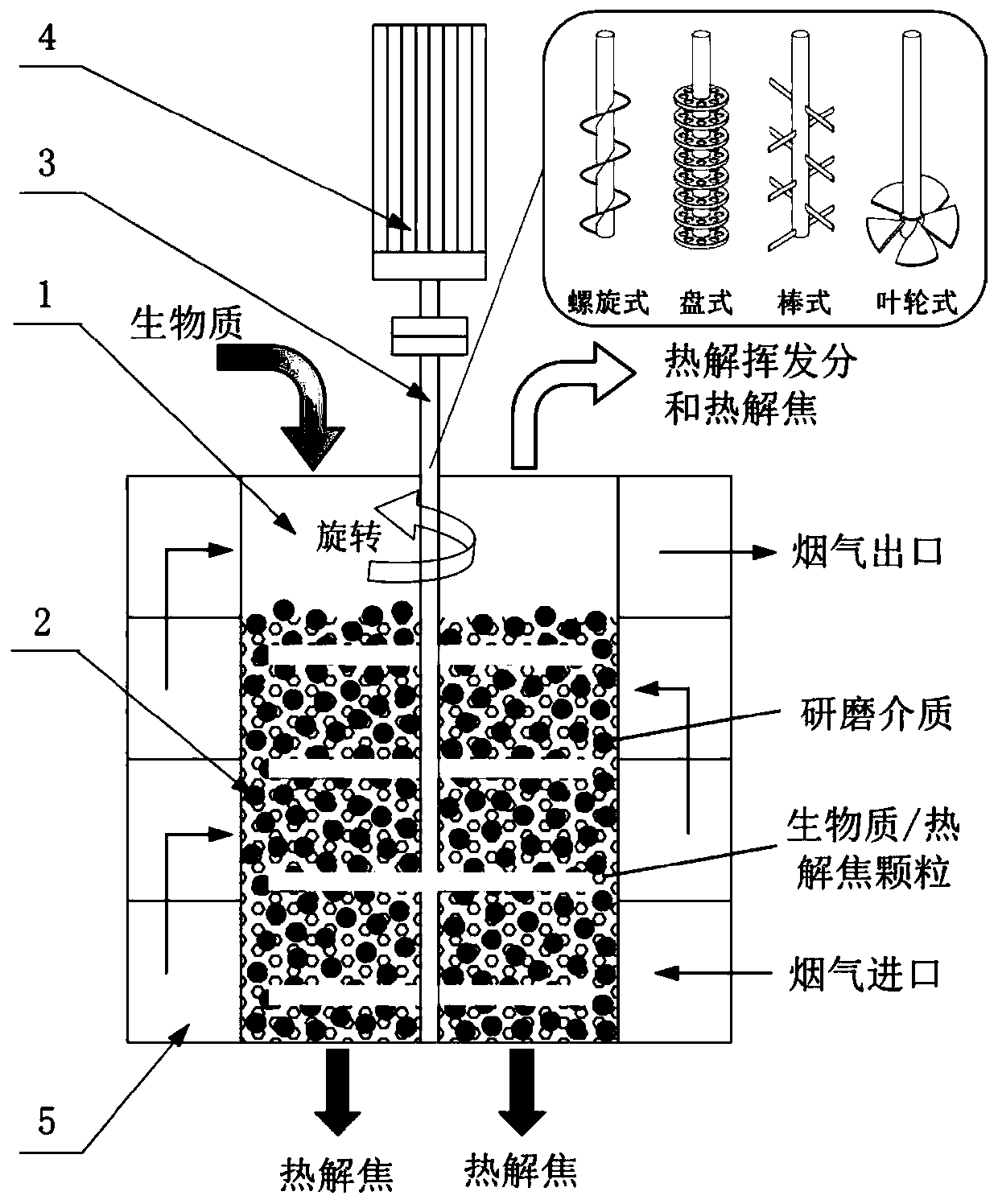

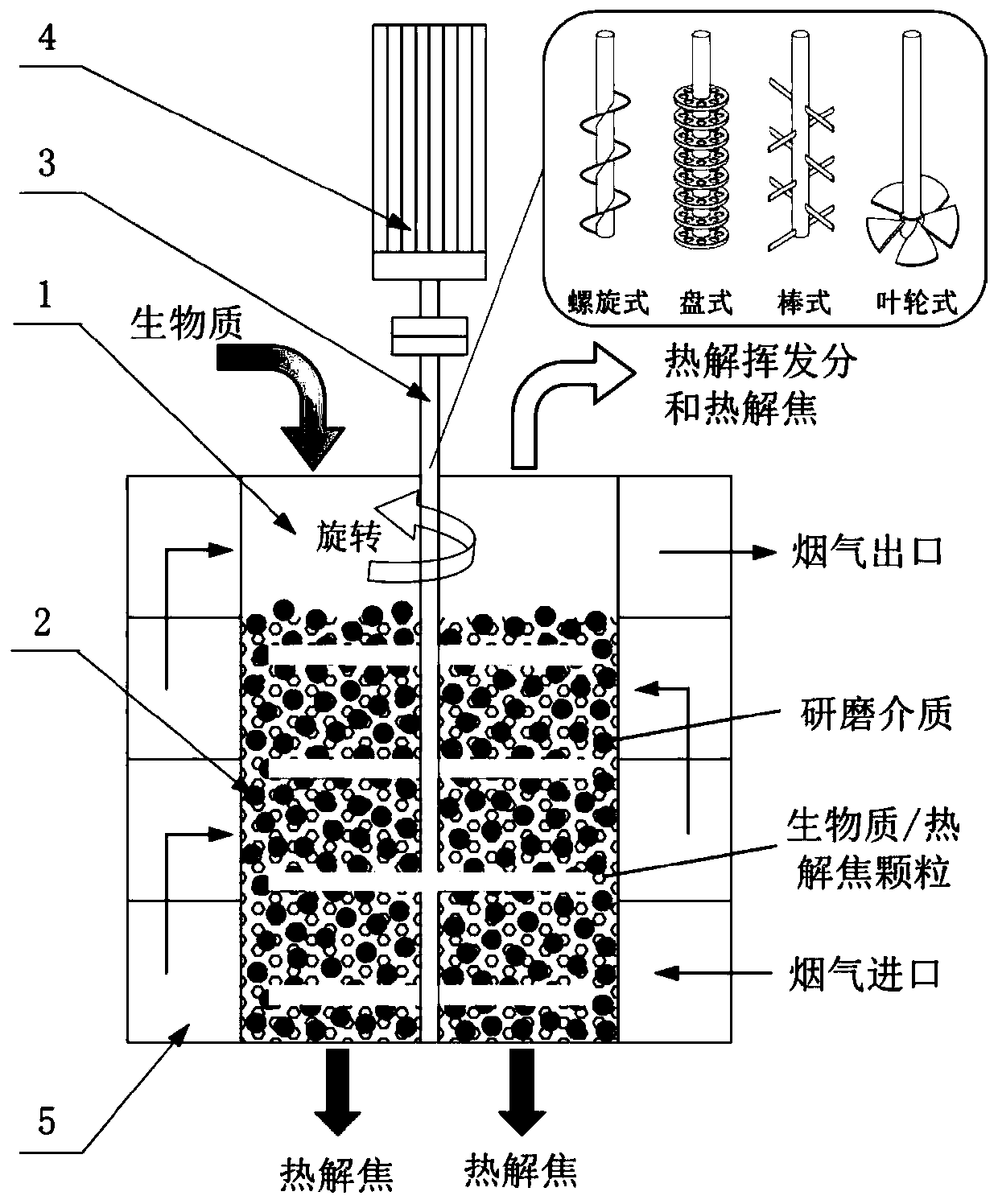

[0021] A vertical stirring grinding pyrolysis device designed by the present invention is such as figure 1 As shown, the pyrolysis reactor 1 includes a cylindrical shape or a truncated cone shape. A high temperature smoke box 5 is sheathed around the outside of the pyrolysis reactor 1, and the inside of the high temperature smoke box 5 is a spiral channel from bottom to top, and the high temperature smoke box 5 A high-temperature flue gas inlet is provided at the bottom of the, and a flue gas outlet is provided on the top of the high-temperature flue box 5.

[0022] Inside the pyrolysis reacto

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap