Complete mixing type sludge treatment method

A completely mixed, sludge technology, used in sewage/sludge fertilizers, fertilization devices, preparation of organic fertilizers, etc., can solve problems such as low disposal efficiency, unstable fermentation cycle, and inability to achieve stable and continuous feeding. The effect of stable fermentation cycle, shortened fermentation cycle and reduced use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

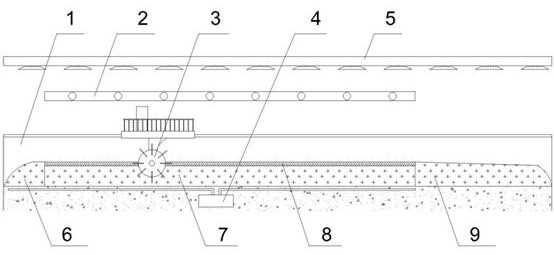

[0020] Example 1: A method of complete hybrid disposal sludge, including the following steps: the urban sewage treatment plant sludge is a compost raw material, straw, bacteria rod to form a composting excimer to form a compost, the sludge moisture content is 75%, the weight of the straw is 30% of the weight of the fertilizer, the weight of the bacteria rod is 5% of the weight of the stack of fertilizers. When the oxygen compost is divided into 55%, the carbon nitrogen ratio is 15, the pH is 6.0, the oxygen concentration is 5 %; The fermentation tank 1 height 2m, the width is 5m, length 80m, the front end of the fermentation groove 1 leaves 5M as the feed region 6, and the rear end leaves 20 cm as the discharge region 9, the intermediate region is the fermentation region 7, the fermentation groove 1 is also The deodorizer 5 is provided, and the deodorizing device 5 is a circulating spray deodorizer. The aeration tank is laid at the bottom of the fermentation tank 1, and the aeration

Example Embodiment

[0021] Example 2: A fully mixed disposal sludge method, including the following steps: the sludge of the urban sewage treatment plant is compost, straw, bacteria rods to form a composting excipients to form a compost, the sludge moisture content is 79%, the weight of the straw is 40% of the weight of the stack of fertilizers, the weight of the bacteria rod is 8% of the weight of the fertilizer, and the water is reduced to 60%, the carbon nitrogen ratio 22, the pH is 7.0, the oxygen concentration is 10 %; The fermentation tank 1 height is 2.5m, the width is 15m, the length is 100m, the front end of the fermentation groove 1 leaves the portion region as the feed region 6, and the rear end is left out as the discharge region 9, the intermediate region is the fermentation region 7, and the fertilizer The fabric to the intermediate region of the fermentation tank 1, the stack of fertilizer after the cloth is 2m, and the fermentation region 7 is turned to the fermentation region 7, and the

Example Embodiment

[0022] Example 3: A method of complete hybrid disposal sludge, including the following steps: the urban sewage treatment plant sludge is a compost raw material, straw, bacteria rod to form a composting excipients to form a compost, the sludge moisture content is 82%, the weight of the straw is 50% of the weight of the stack, the weight of the bacteria rod is 10% of the weight of the stack of fertilizers. When the oxygen compost is divided into 65%, the carbon nitrogen ratio 30, the pH is 8.0, the oxygen concentration is 15 %; The fermentation tank 1 height 3m, width 30m, length 120m, the front end of the fermentation groove 1 leaves 10M as the feed region 6, the rear end leaves 28m as the discharge region 9, the intermediate region is the fermentation area 7, the stack of fertilizer cloth The fermentation tank 1 is in the middle of the fermentation tank, the stack of fertilizer is 2.5m, and the fermentation region 7 is turned to the fermentation region 7, and the fertilizer fermentat

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap