Semi-detached multi-frame graphite boat

A graphite boat and graphite technology, applied in the field of graphite boats for solar photovoltaic PECVD, can solve problems such as difficult assembly, inconvenient handling and use, and increased defective rate, so as to reduce defective product rate, prolong cumulative deviation, and increase production capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

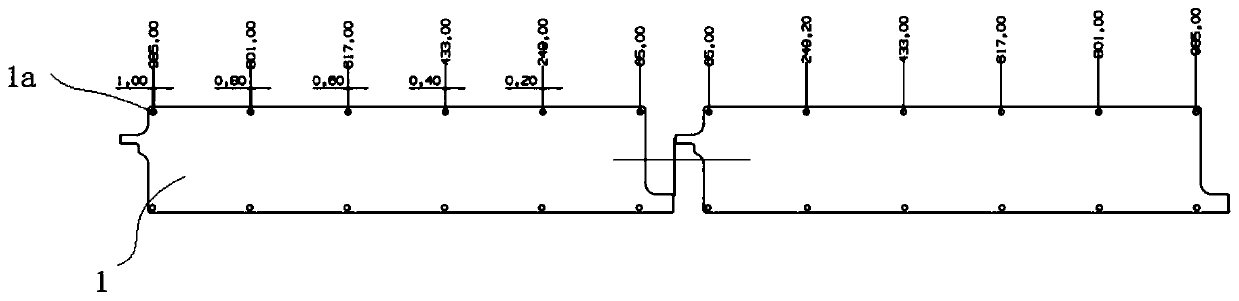

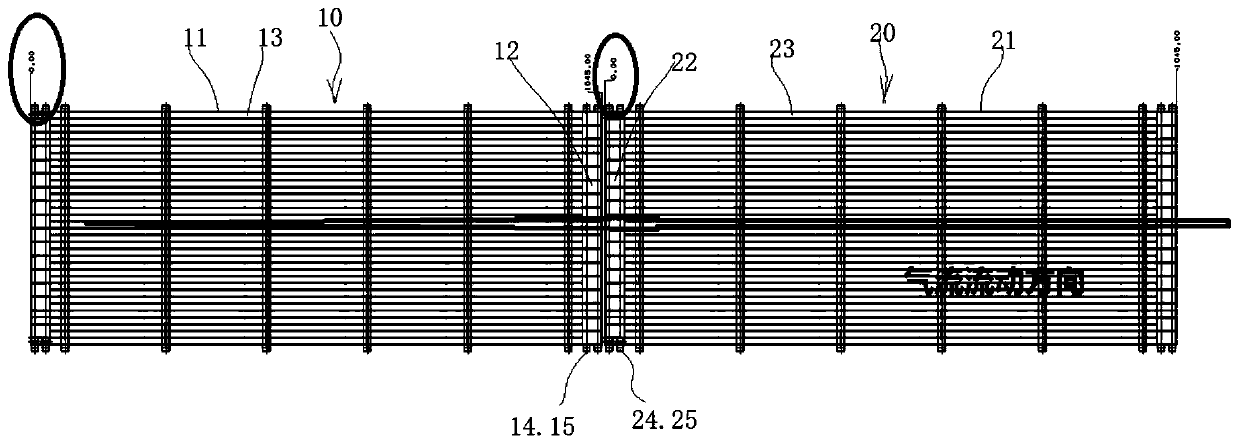

[0026] see figure 2 , the double-combined multi-frame graphite boat shown in the figure includes two multi-frame graphite boats 10, 20, of course it is not limited to two multi-frame graphite boats 10, 20, and can be connected in series by more than two multi-frame graphite boats .

[0027] Each multi-frame graphite boat 10, 20 is a five-frame graphite boat with very mature technology, and the loading capacity of each five-frame graphite boat is within 450.

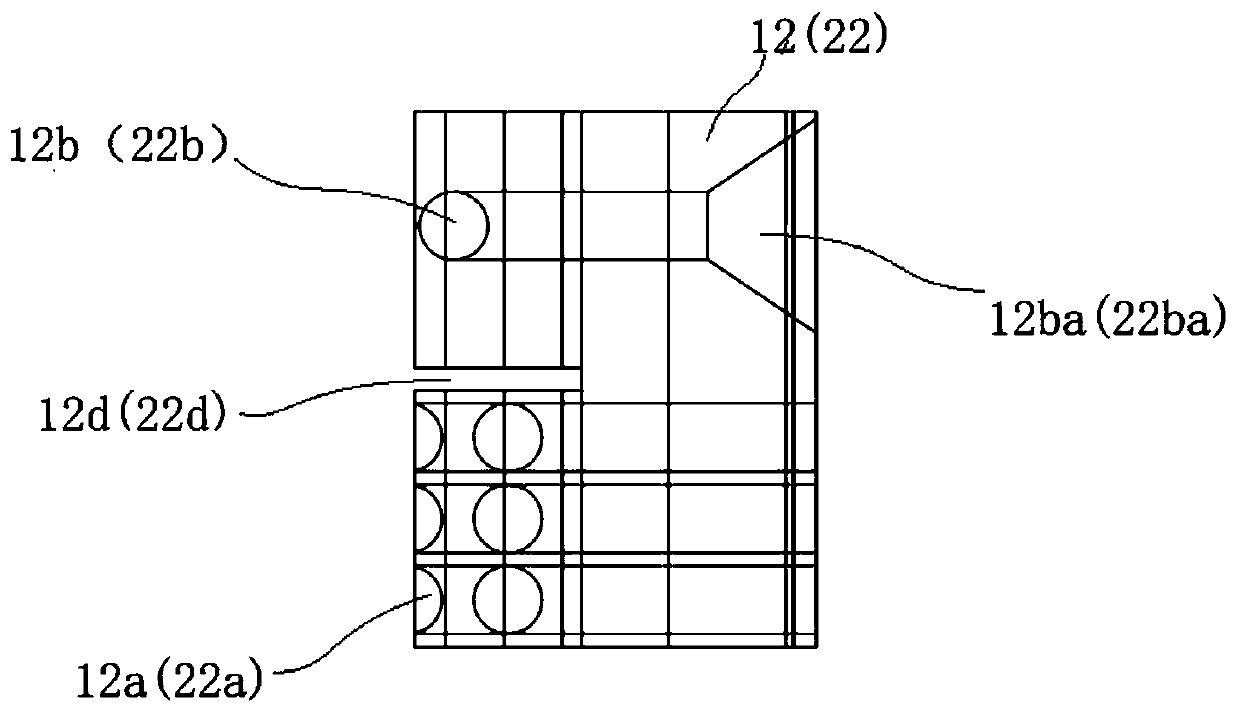

[0028] The present invention is characterized in that: the double-piece multi-frame graphite boat is connected in series by two multi-frame graphite boats 10, 20, and passes between the ends of two adjacent graphite boat sheets 11, 21 of each multi-frame graphite boat 10, 20 A graphite spacer 12, 22 and two bolt rods 14, 24 and nuts 15, 25 are connected. The ingenious use of two multi-f

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap