High-solid transparent paint and preparation method thereof

A clear paint, high-solid technology, applied in the field of coatings, can solve the problems of easy blooming, difficult to color, poor adhesion, etc., to achieve the effect of easy coloring, less blooming, and paint saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

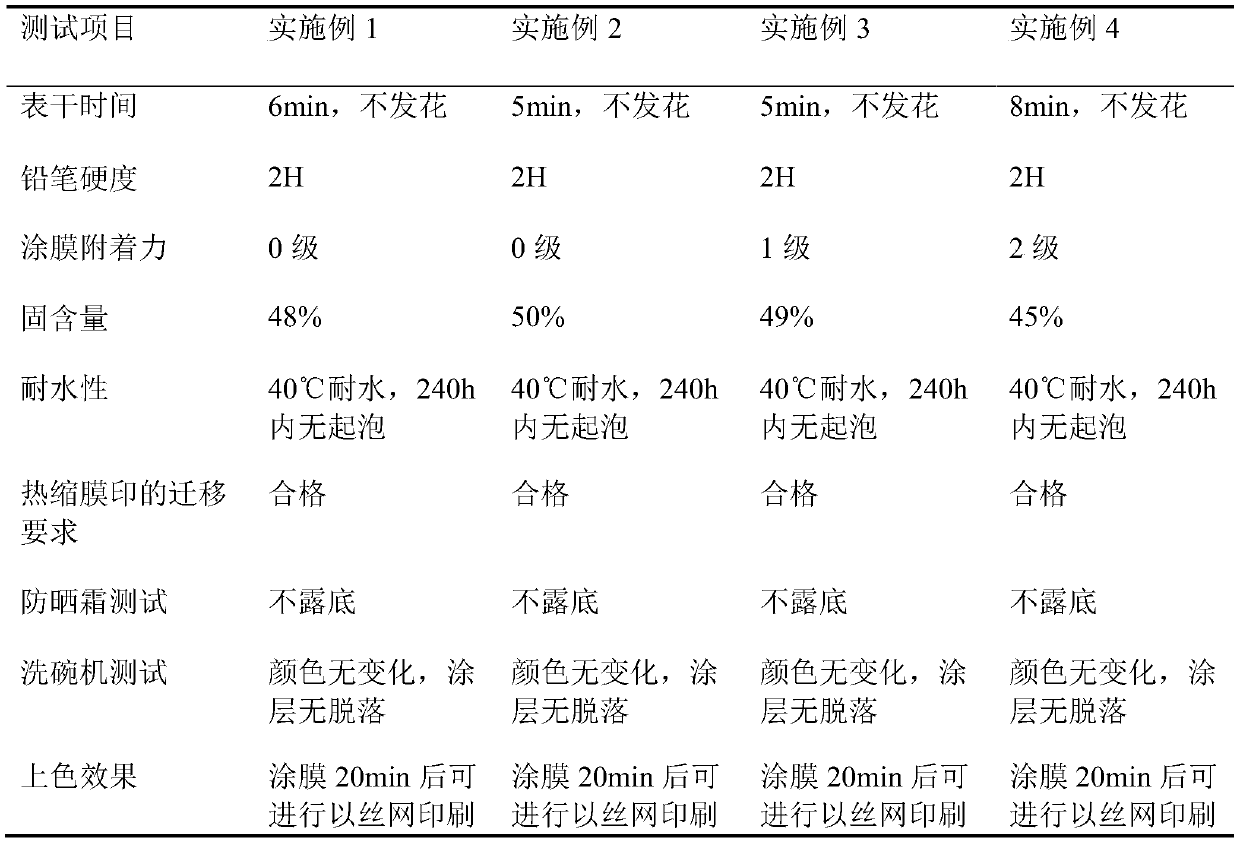

Examples

Example Embodiment

[0037] Example 1

[0038] A high-solid transparent paint, which includes the following weight percentages of raw materials: acrylic resin 50%, amino resin 25%, epoxy resin 5%, pigment 1%, polymer phosphate 2%, leveling agent 1%, n-butyl Alcohol 16%.

[0039] The preparation method of high-solid transparent paint includes the following steps:

[0040] (1) After mixing the pigments evenly, place them in a horizontal grinder for grinding. The grinding air pressure is 0.05MPa, the grinding temperature is 30°C, and the grinding time is 10 hours per 500Kg. At the same time, the cavity of the grinder is cooled by circulating water;

[0041] (2) Add acrylic resin, amino resin, epoxy resin, polymerized phosphate ester, leveling agent, thinner for tack adjustment, and the pigment ground in step (1) into the high shear dispersing machine in sequence. Adjust the speed of the shearing disperser to 1200r / min, stirring for 20min at room temperature, then adjust the speed of the high-shearing dispers

Example Embodiment

[0043] Example 2

[0044] A high-solid transparent paint, which includes the following weight percentages of raw materials: acrylic resin 55%, amino resin 25%, epoxy resin 5%, pigment 1%, polymer phosphate 2%, leveling agent 1%, xylene 11%.

[0045] The preparation method of high-solid transparent paint includes the following steps:

[0046] (1) Mix the pigments evenly and place them in a horizontal grinder for grinding. The grinding air pressure is 0.08MPa, the grinding temperature is 35°C, and the grinding is 20h per 500Kg. At the same time, the cavity of the grinder is cooled by circulating water;

[0047] (2) Add acrylic resin, amino resin, epoxy resin, polymerized phosphate, leveling agent, thinner for adjusting viscosity, and the pigment ground in step (1) into the high-shear disperser one by one, first Adjust the speed of the shear disperser to 1300r / min, stir for 15min at room temperature, then adjust the speed of the high shear disperser to 900r / min, stir for 10min at room

Example Embodiment

[0049] Example 3

[0050] A high-solid transparent paint, which includes the following raw materials in weight percentage: acrylic resin 56%, amino resin 22%, epoxy resin 4%, pigment 2%, polymer phosphate 1%, leveling agent 3%, ethylene dichloride Butyl alcohol 12%.

[0051] The preparation method of high-solid transparent paint includes the following steps:

[0052] (1) After mixing the pigments evenly, place them in a horizontal grinder for grinding. The grinding air pressure is 0.10MPa, the grinding temperature is 40℃, and the grinding is 25h per 500Kg. At the same time, the cavity of the grinder is cooled by circulating water;

[0053] (2) Add acrylic resin, amino resin, epoxy resin, polymerized phosphate, leveling agent, thinner for adjusting viscosity, and the pigment ground in step (1) into the high-shear disperser one by one, first Adjust the speed of the shear disperser to 1400r / min, stir at room temperature for 10 minutes, then adjust the speed of the high shear disperser to

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap