Gas-proof plugging coating for coal mine tunnel

A coal mine roadway and anti-gas technology, which is applied in the direction of fireproof coatings, conductive coatings, alkali metal silicate coatings, etc., can solve the problems of poor fire resistance, poor air tightness, easy cracks, etc., and achieve good construction performance, Not easy to fall off, good bonding strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

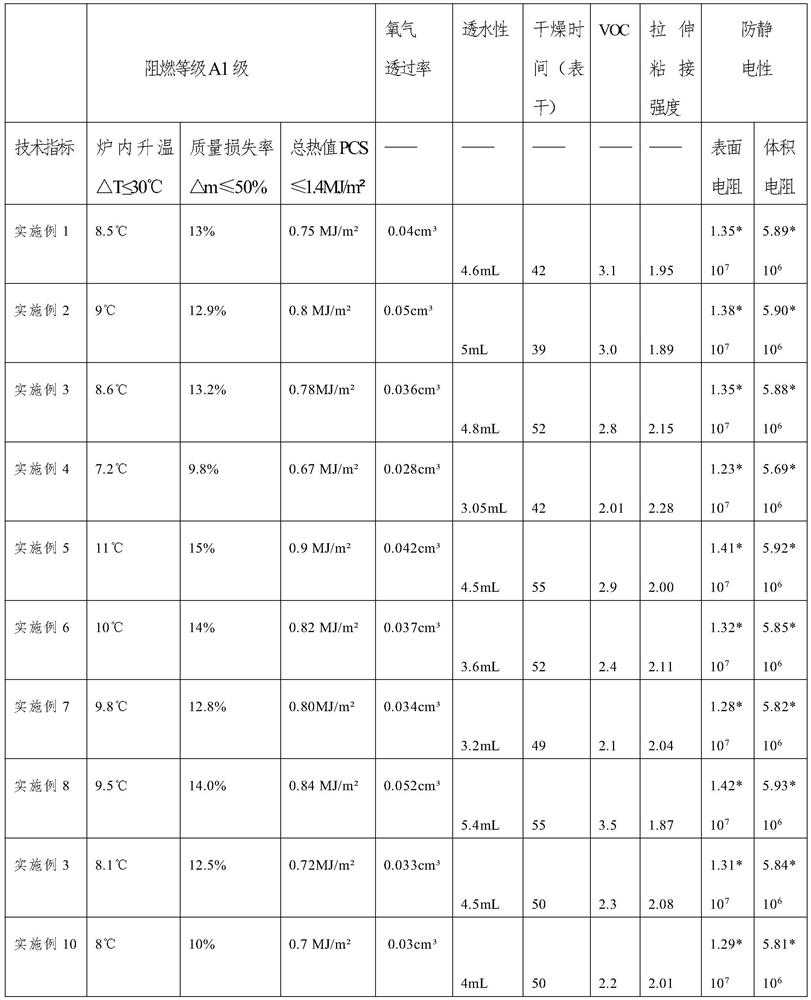

Examples

Example Embodiment

[0040] Example 1

[0041] Roadway one kind of gas present invention anti-blocking coating material, comprising: 20 parts by mass of potassium silicate, 2 parts by mass of sodium silicate, 0.4 parts by mass of silicon phosphate, 15 parts by mass of quartz powder, 15 parts by mass of decarbonization of fly ash, 15 parts by weight of wollastonite, 5 parts by mass of needle-like wollastonite, 1.5 parts by mass of carbon fiber, 6 parts by mass of water. The liquid potassium silicate is potassium silicate, modulus of 28; a liquid sodium silicate, modulus of 2.5. Quartz powder 200 mesh, 300 mesh carbon fiber.

[0042] Preparation of the anti-gas coal mine tunnel plugging coatings are:

[0043] S1: The silicon phosphate adding water dispersible formulation;

[0044]S2: Mix the potassium silicate and sodium silicate, dispersion of 6 min under stirring rotational speed of 400r / min, in the dispersion process, in proportion to quartz powder, de-carbona gray ash, silica grayite, needle-shaped

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface dry time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap