Municipal drainage concrete socket-and-spigot pipe pillow prefabricated plastic mold

A technology for municipal drainage and plastic moulds, which is applied in the direction of molds, etc., can solve problems such as failure to meet pipeline foundation construction technology and safety requirements, rectangular pads and bricks with single specifications, and failure to meet pipelines, etc., to achieve excellent chemical resistance, Excellent electrical performance and guaranteed molding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

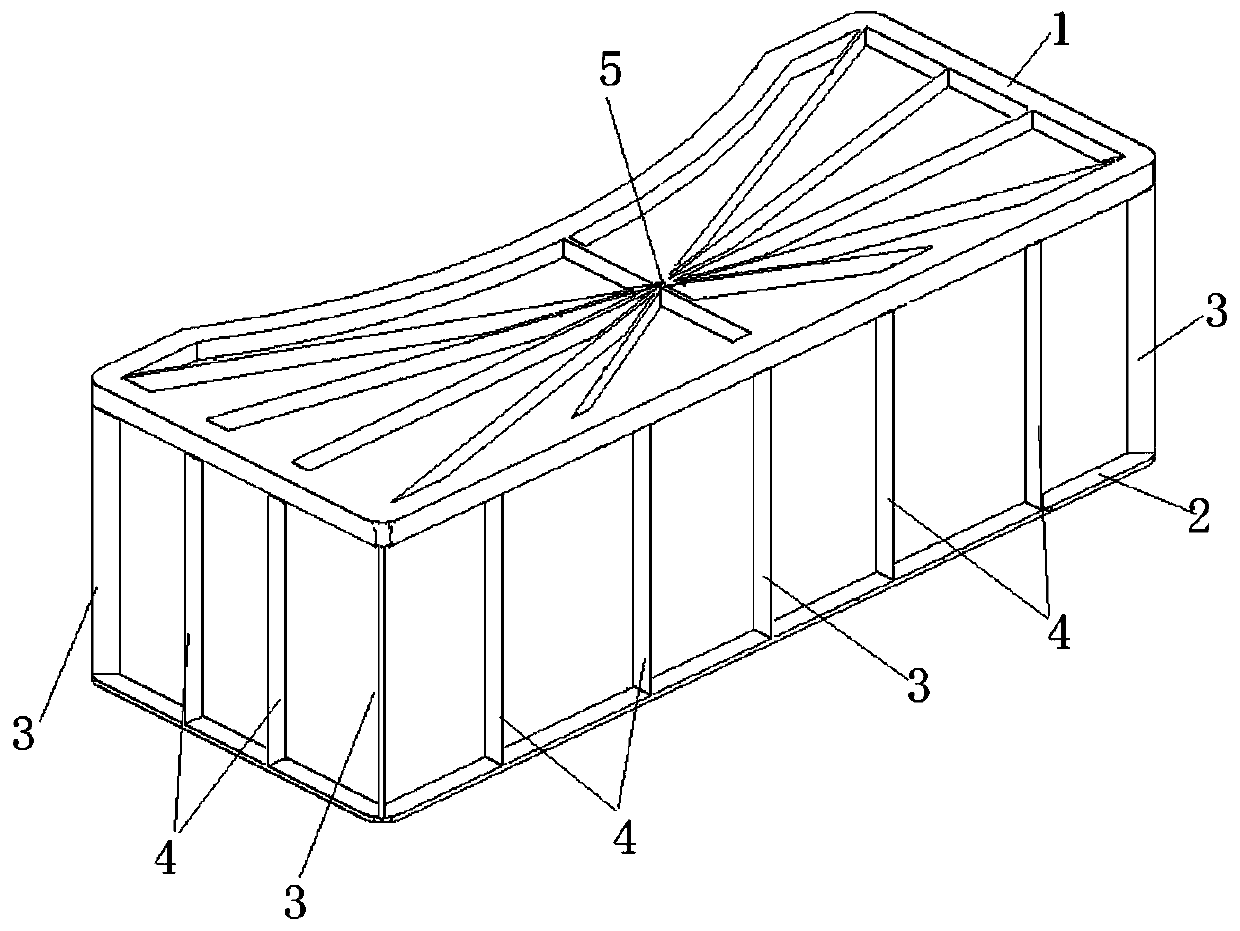

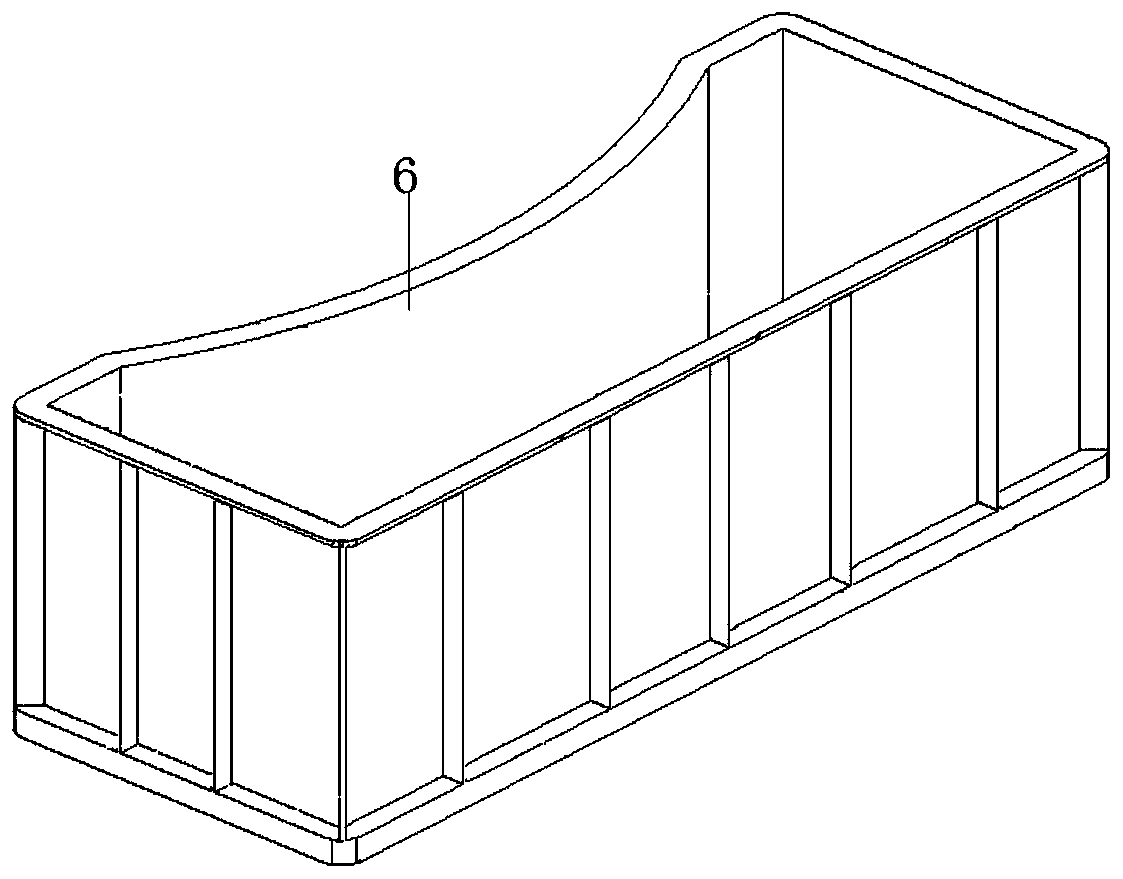

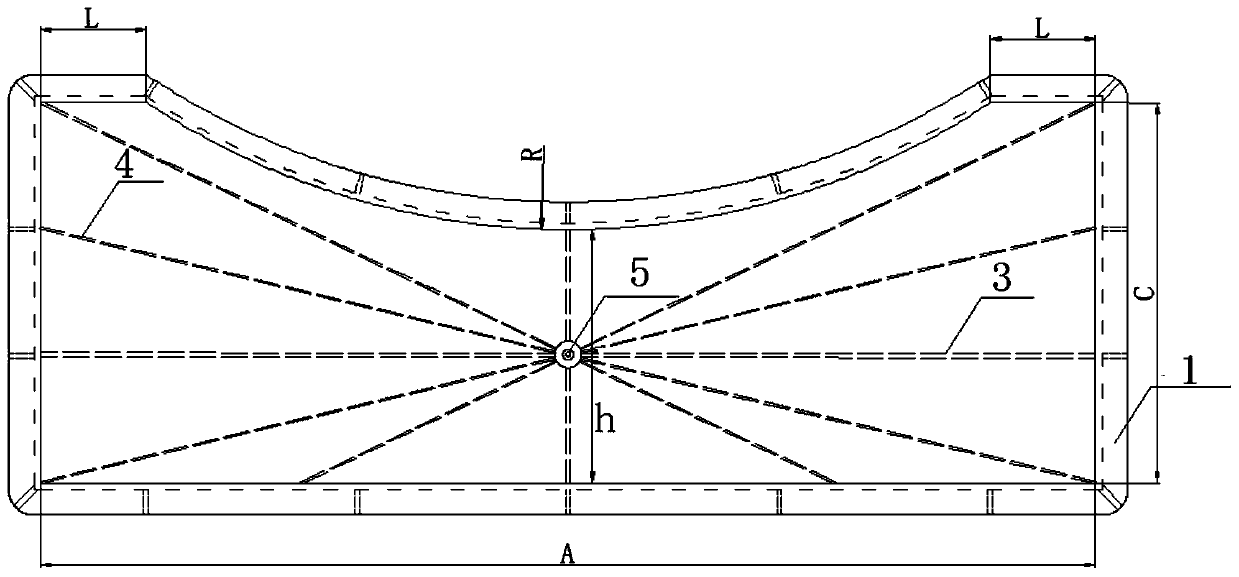

[0021] Example: A prefabricated plastic mold for municipal drainage concrete socket type pipe pillows, including a lower mold and an upper mold, the upper mold and the lower mold are made of ABS plastic; the lower mold is a hollow frame structure, The bottom and top of the frame structure are open. The inside of the frame structure is a rectangular parallelepiped structure with a concave curved surface 6. The bottom frame 2 is provided around the bottom of the frame structure, and reinforcement ribs are evenly provided on the sides of the frame structure. The reinforcing ribs include a main rib 3 and a secondary rib 4; the thickness of the main rib 3 of the frame structure is 3 mm, the thickness of the secondary rib 4 is 2 mm, the width of the lower frame 2 is 2 cm, and the main rib 3 of the frame structure , The secondary rib 4 and the lower frame 2 form a reinforced whole; the main rib 3 on the frame structure is vertically arranged in the middle of the long side of the frame str

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap