Die cleaning device for aluminum alloy production

A cleaning device and technology for aluminum alloys, which are applied in the directions of cleaning methods using tools, cleaning methods and utensils, and cleaning methods using liquids, etc., can solve the problems of improving the defective rate of aluminum alloy profiles, being easily contaminated with oil stains and punching debris, etc. , to achieve the effect of convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

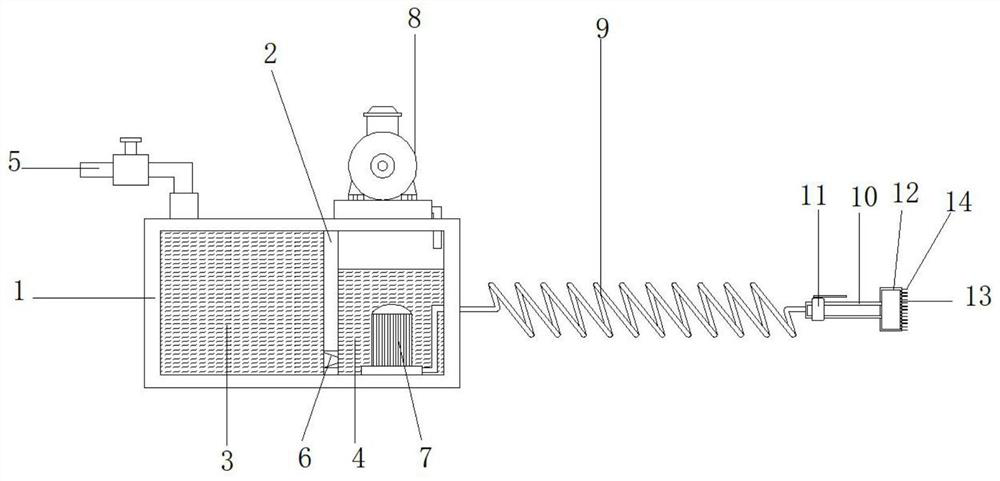

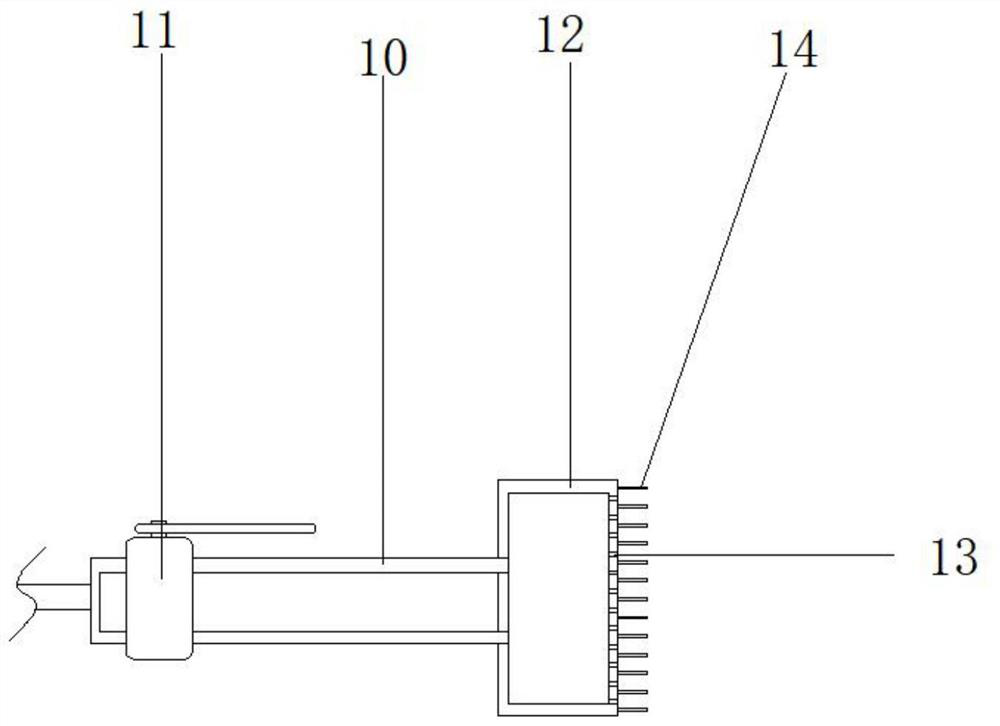

[0017] refer to Figure 1-2 , a mold cleaning device for aluminum alloy production, comprising a pressure box 1, a partition 2 is welded on the inner wall of the pressure box 1, and the partition 2 divides the interior of the pressure box 1 into a water storage chamber 3 and a pressurized chamber 4, There is a mounting hole at the lower part of the outer wall of the partition plate 2, a check valve 6 is fixed in the mounting hole, a water pump 7 is fixed on the bottom inner wall of the pressurized chamber 4, an air pump 8 and a water pump 8 are fixed on the outer wall of the top of the pressurized chamber 4 The water outlet end is connected with a spiral conveying pipe

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap