Herringbone tooth cutting method for servo control compensation

A cutting method and servo control technology, which is applied in the direction of program control, computer control, general control system, etc., can solve the problems of high scrap rate and difficult operation of initial cutting herringbone teeth, so as to shorten the manufacturing cycle and save labor costs , Improve the effect of cutting accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0026] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings. It should be understood that the preferred embodiments are only for illustrating the present invention, not for limiting the protection scope of the present invention.

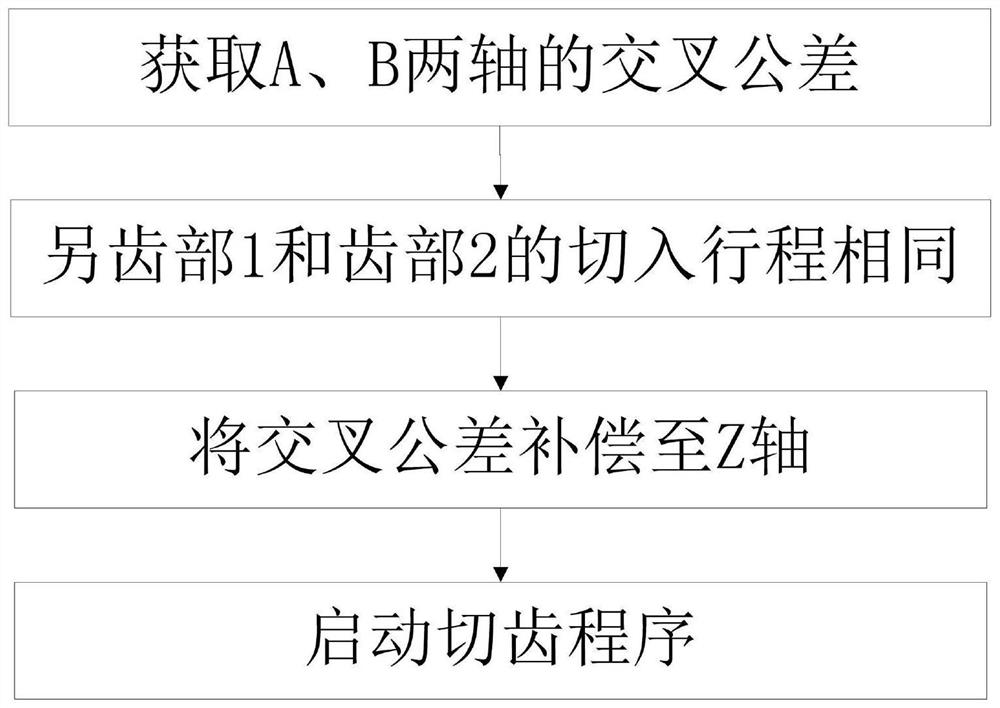

[0027] The present invention proposes a servo-controlled and compensated herringbone tooth cutting method. The method is summarized as: obtaining the AB axis cross tolerance through testing, and then optimizing the cutting parameters, that is, ensuring the feed stroke of the herringbone tooth 1, tooth 2 gear It is the same, and the AB axis cross tolerance is compensated to the Z axis control in the numerical control system, and finally achieves a smaller herringbone tooth centering tolerance and improves herringbone tooth cutting accuracy.

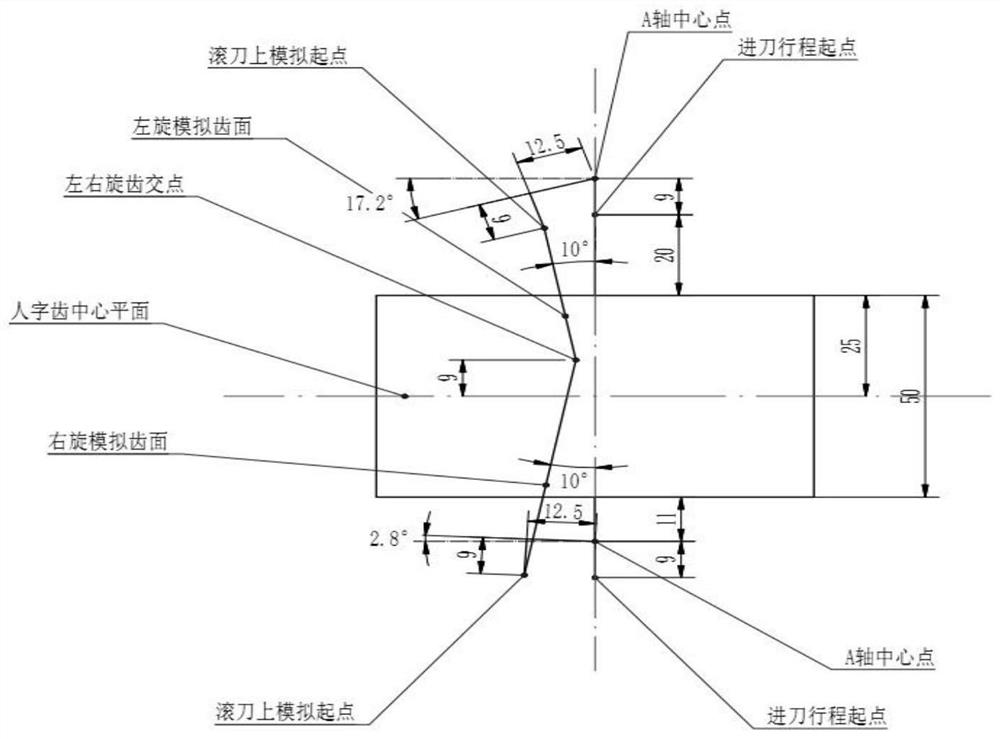

[0028] Specific, such as figure 1 Shown.

[0029] S1: Due to the cross tolerance of the AB axis and AC axis of the machine tool, the starting poi

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap