Traction device of material station for belt material processing

A pulling device and material technology, applied in the field of belt material processing and forming equipment, can solve the problems of high labor intensity, hidden danger of manual pulling, and low efficiency, and achieve the effects of reducing production cost, improving production efficiency, and facilitating pulling operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings.

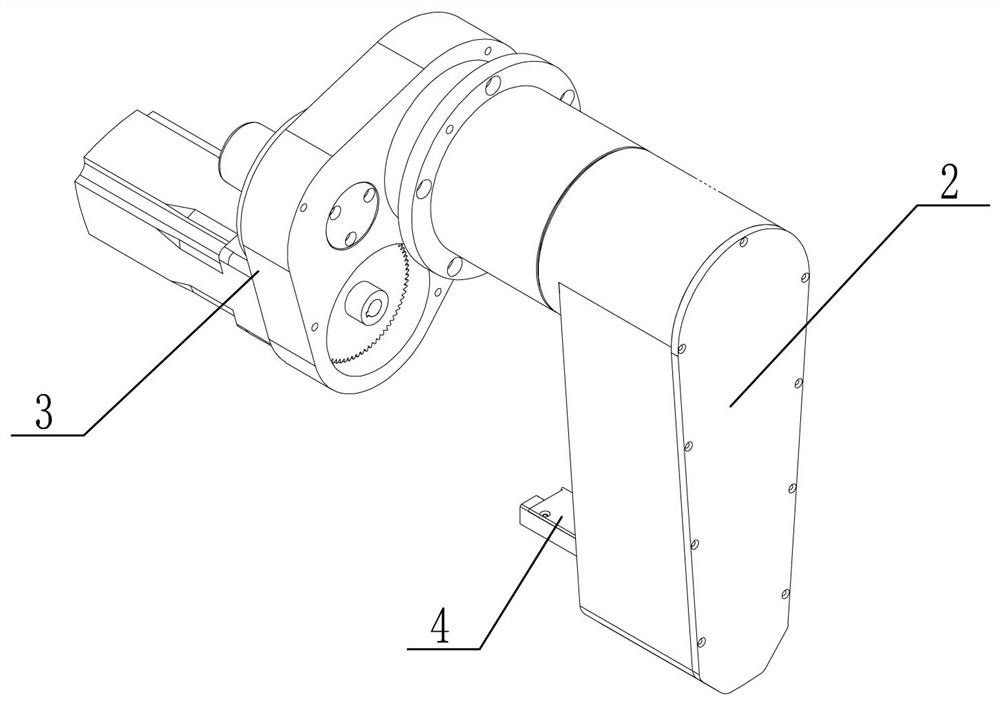

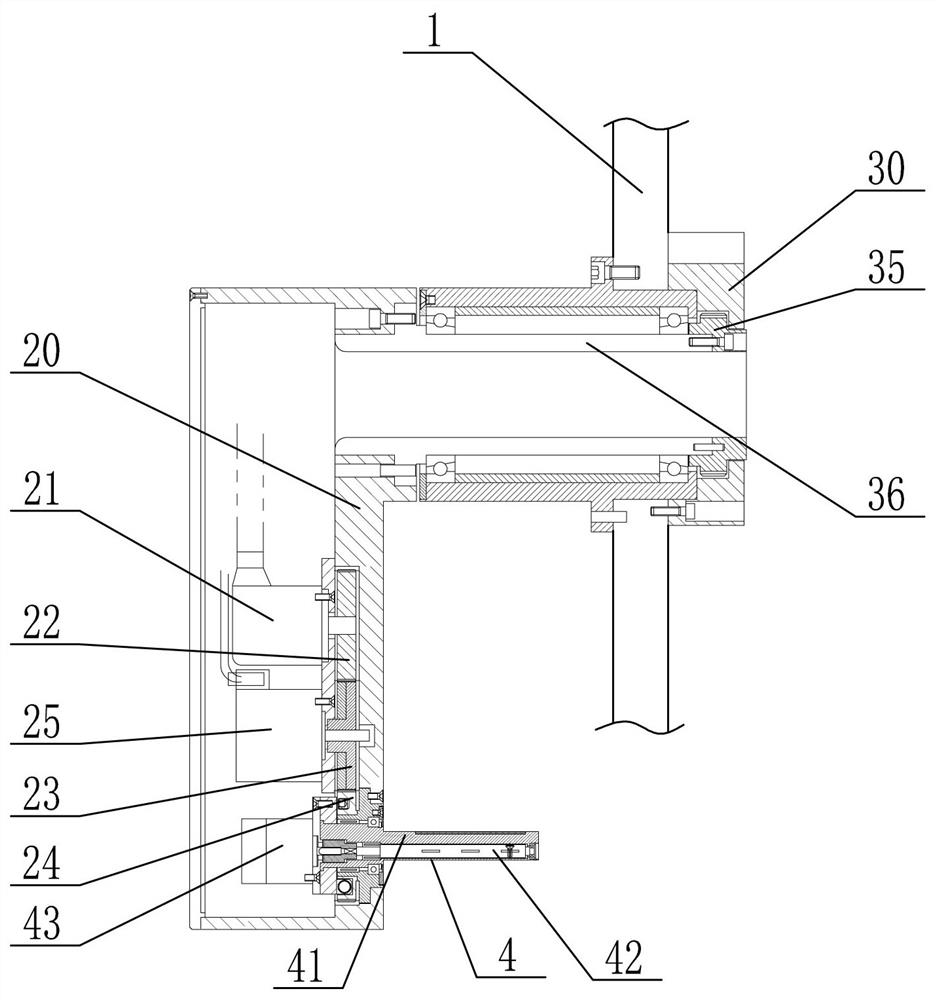

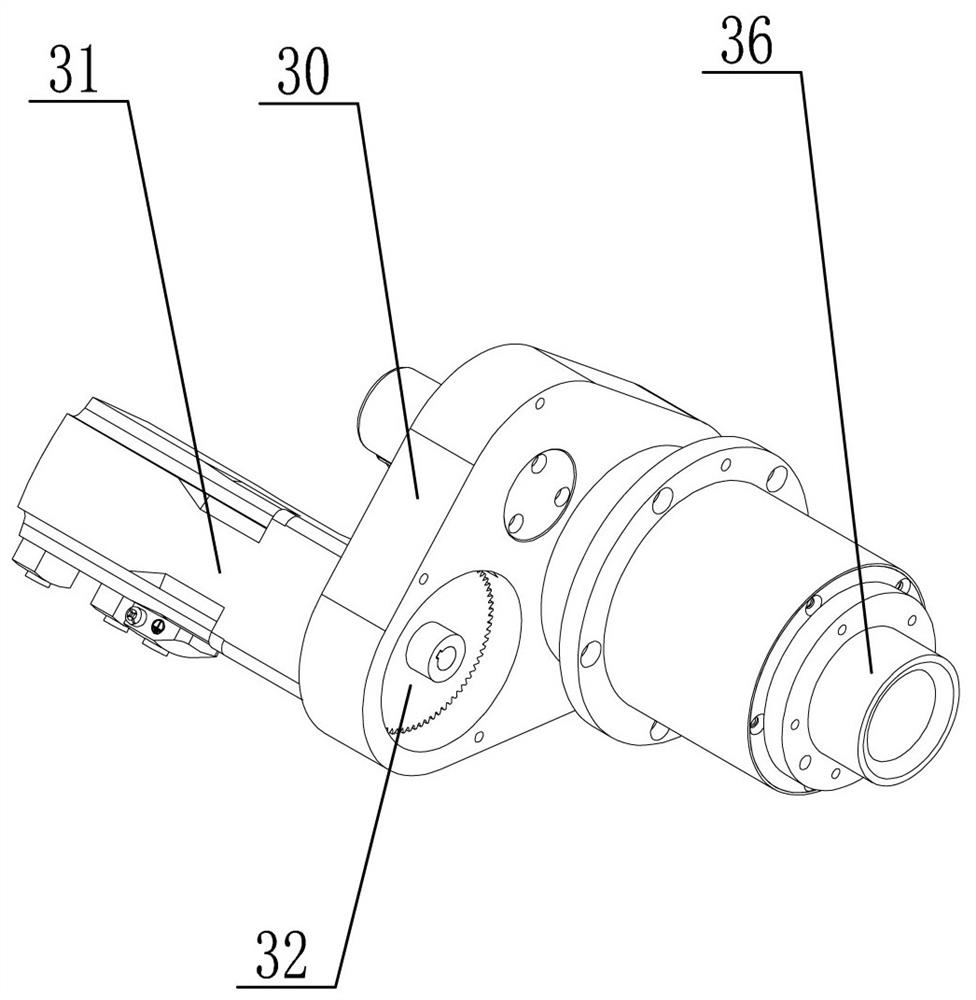

[0025] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6As shown, a material traction device for strip-shaped material processing includes a main vertical plate 1, a swing arm mechanism 2 and a driving mechanism 3, and the main vertical plate 1 is vertically arranged to support the swing arm mechanism 2 and the driving mechanism 3. The driving mechanism 3 is arranged on the rear end surface of the main vertical plate 1, and the output shaft 36 of the driving mechanism 3 passes through the main vertical plate 1 and is connected with the swing arm mechanism 2 located at the front end surface of the main vertical plate 1. The driving mechanism 3 To provide power for the swing of the swing arm mechanism 2, the swing arm mechanism 2 includes a swing arm housing 20, an angle adjustment motor 21, an angle driving gear 22, an angle inter

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap