Nitrogen-phosphorus flame-retardant polystyrene block copolymer and preparation method thereof

A technology of polystyrene block and polystyrene, which is applied in the field of nitrogen-phosphorus flame-retardant polystyrene block copolymer and its preparation, which can solve the problem of weak binding effect, affecting the long-term flame-retardant performance of products, loss of flame-retardant components, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

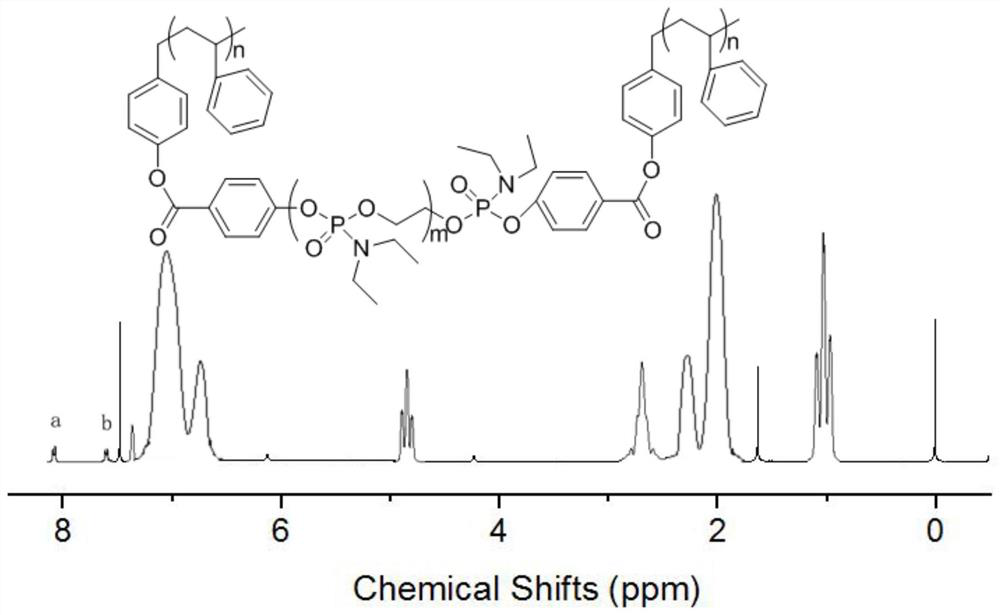

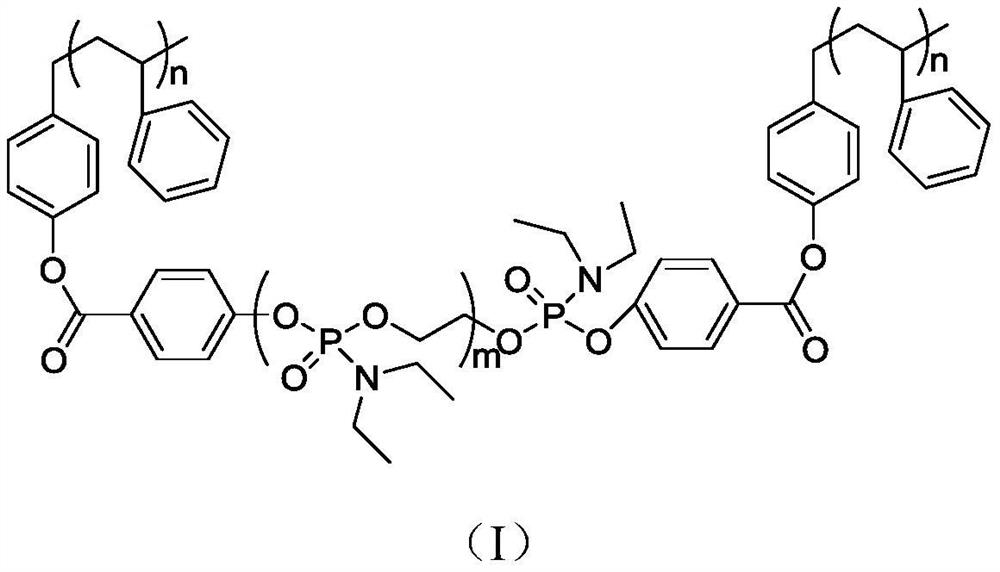

Image

Examples

Embodiment 1

[0024] Add diethyl dichlorophosphonamide (10mmol), triethylamine (10mmol) and twice the mass of diethyldichlorophosphonamide in a three-necked flask equipped with a reflux condenser, a constant pressure dropping funnel, and a magnetic stirring device. chloroform, fully dissolved and mixed uniformly; weigh ethylene glycol (10mmol) and dissolve it in twice the mass of chloroform, put it into a constant pressure dropping funnel, and remove it from the ice bath after dropping it in 1h under ice bath, slowly After heating up to 70°C and refluxing for 6 hours, inject a chloroform solution of p-hydroxybenzoic acid (2.5 mmol) with a disposable needle, continue to keep warm and reflux for 3 hours to complete the reaction, cool to room temperature, distill off the solvent under reduced pressure, and take the filtrate again after suction filtration. Dissolve in chloroform, extract with distilled water three times, take the organic phase and distill off the solvent under reduced pressure to o

Embodiment 2

[0026] Add the reactive flame retardant terminal benzoic acid poly(diethylamino)ethylene phosphate (4.0mmol) and 20ml of anhydrous tetrahydrofuran THF into the reactor, and after the reaction temperature rises to 70°C, slowly add SOCl 2 (6.0mmol), dropwise completed reaction 2h, after finishing reaction, decompression distillation removes SOCl 2 and THF to obtain the reaction type flame retardant terminal benzoic acid poly (diethylamino) ethylene glycol phosphate acid chloride product.

[0027] Hydroxyl-terminated polystyrene (40mmol) was added into a 50ml Schlenk bottle, and after pumping nitrogen three times, N 2 Under protection, add 30ml of anhydrous toluene into a disposable syringe, raise the temperature to 70°C, inject 1ml of pyridine after the hydroxyl-terminated polystyrene is completely dissolved, and after stirring for 30 minutes, add the above-mentioned reactive flame retardant terminal benzoic acid dissolved in toluene dropwise Poly (diethylamino) ethylene glycol ph

Embodiment 3

[0029] Before processing, vacuum-dry the nitrogen-phosphorus flame-retardant polystyrene block copolymer at 80°C for 12h, and add 60wt% nitrogen-phosphorus flame-retardant polystyrene block copolymer on an open heat mixer with a twin-roller temperature of 235°C After being melted and covered with rolls, the sheet is evenly produced after mixing for 10 minutes, hot-pressed on a flat vulcanizing machine at 240°C for 10 minutes, cold-pressed at room temperature for 8 minutes, and produced. Flammability test.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap