Embossing device for producing asphalt waterproof coiled material

A bitumen waterproof membrane and embossing technology, which is applied in the field of bitumen waterproof membrane production, can solve the problems of offset of bitumen waterproof membrane, and achieve the effects of avoiding offset, improving embossing quality, and increasing pulling force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0029]Example 1

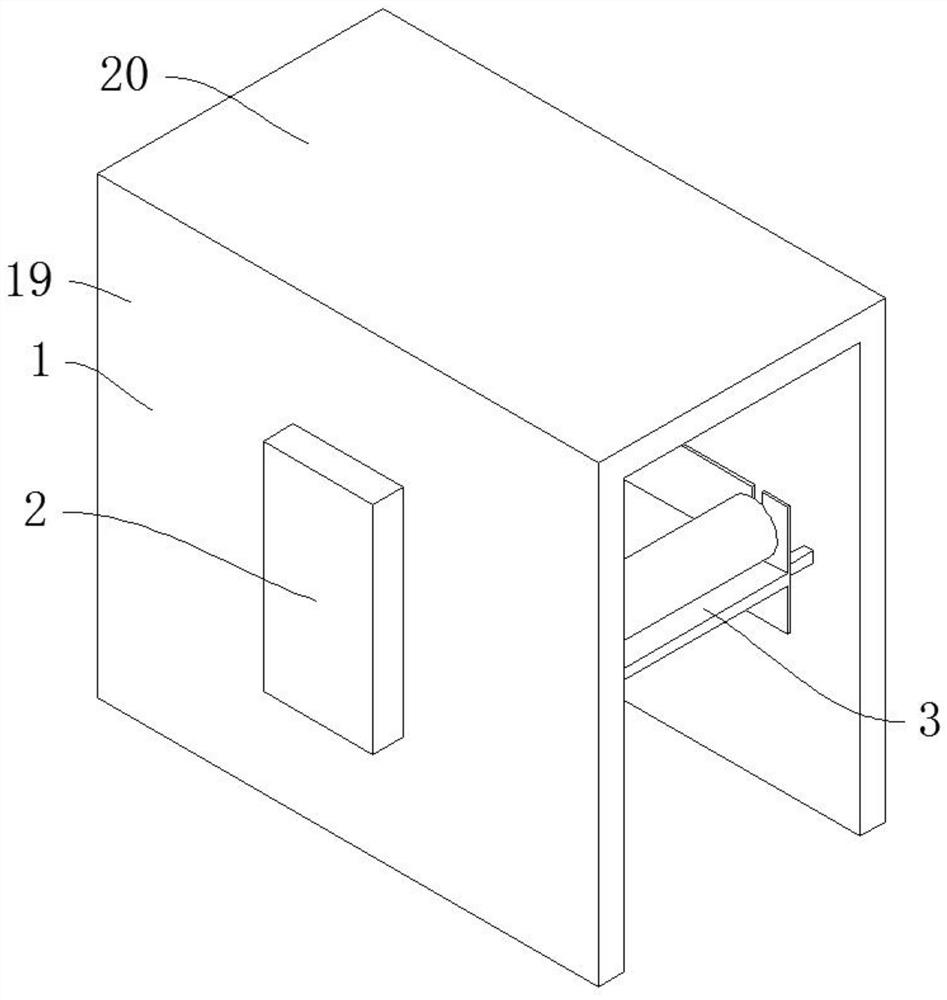

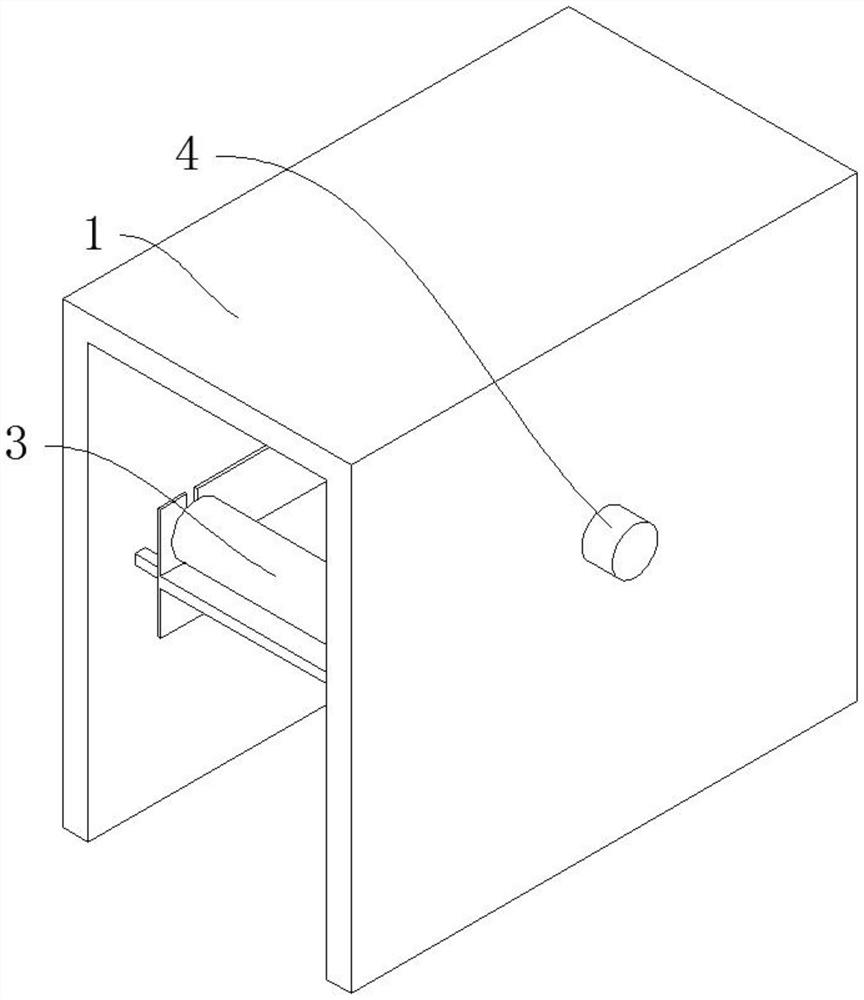

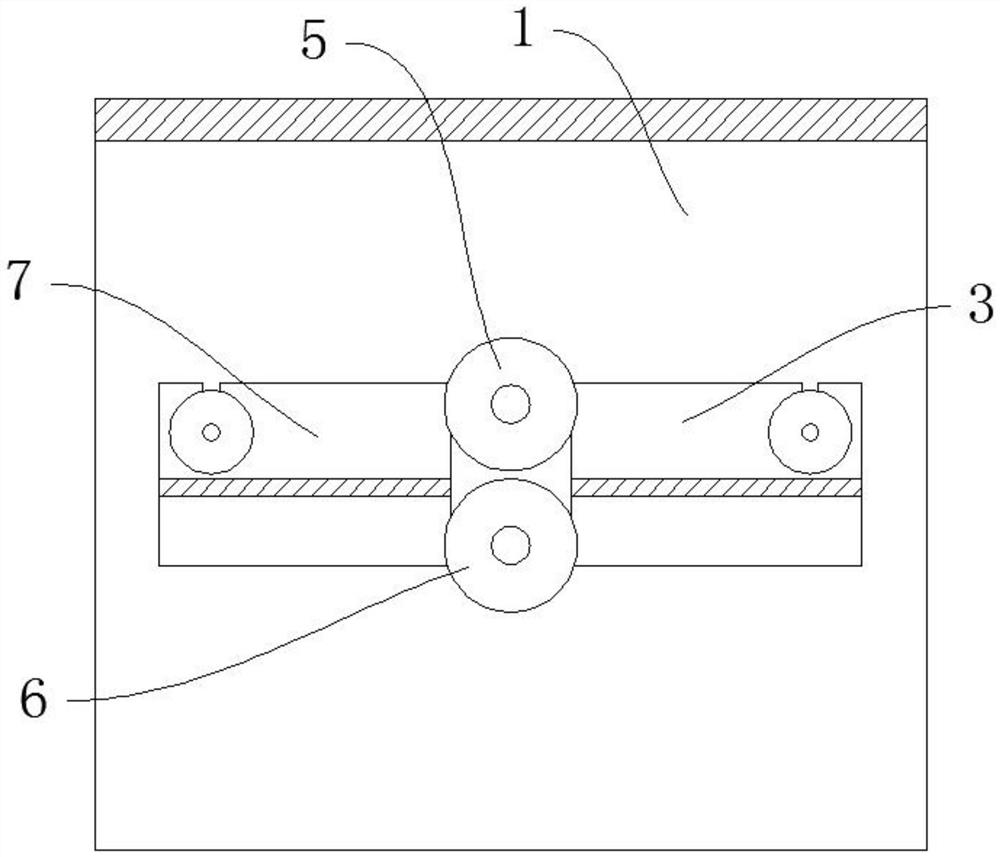

[0030]SeeFigure 1-Figure 5, The embossing device used for the production of bituminous waterproof membranes, including the frame 1, the embossing roller 5, and the supporting roller 6. The frame 1 includes a top plate 20 to protect internal parts. The top plate 20 is provided with side plates 19 at the front and back to support the internal parts A motor 4 is installed behind the frame 1 to provide rotation power. A gear box housing 2 is installed in the front of the frame 1 to protect internal parts. The gear box housing 2 is provided with a driving gear 11 to drive the driven gear 12 to rotate, below the driving gear 11 A passive gear 12 is installed to drive the supporting roller 6 to rotate. An embossing roller 5 is installed in the frame 1 to support the embossing boss 8. The embossing roller 5 is provided with an embossing boss 8 on the surface to form the upper surface of the asphalt waterproof membrane Pattern, the two ends of the embossing roller 5 are symmetric

Example Embodiment

[0032]Example 2

[0033]On the basis of the above embodiment:

[0034]The motor 4 is connected with the frame 1 by bolts, the gear case 2 and the frame 1 are snap-connected. The bolt connection is convenient for disassembly and assembly of the motor 4, and the snap connection is convenient for disassembly and assembly of the gear case 2 for maintenance.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap