Multifunctional juicing production device for fruits with kernels

A technology of multi-functional belt and production equipment, applied in the fields of press, juice extraction, food science, etc., can solve the problems that the vertical press does not have automatic discharging function, is not suitable for large-scale continuous production, and has high residual moisture content. Achieve the effect of facilitating mass production, ensuring the taste of juice, and reducing moisture content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0026] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

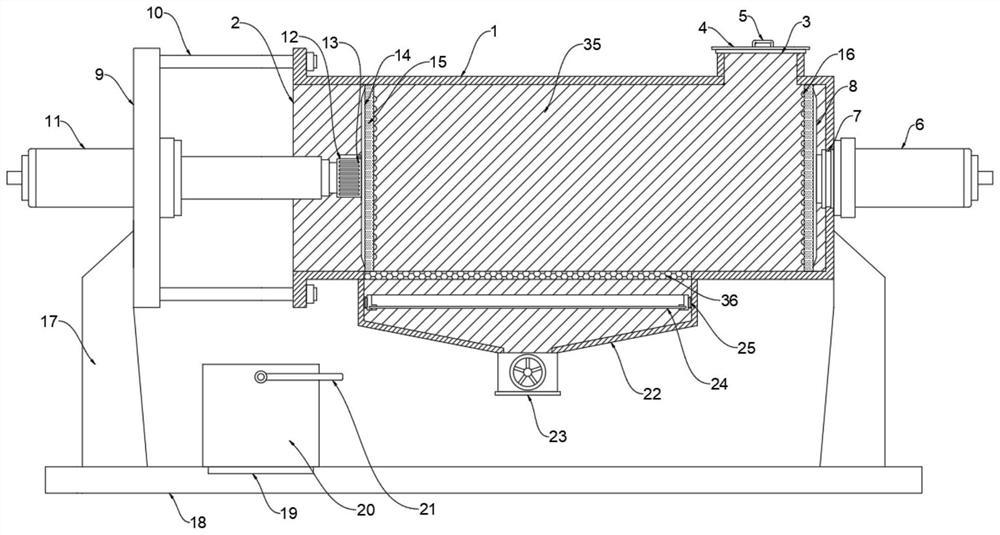

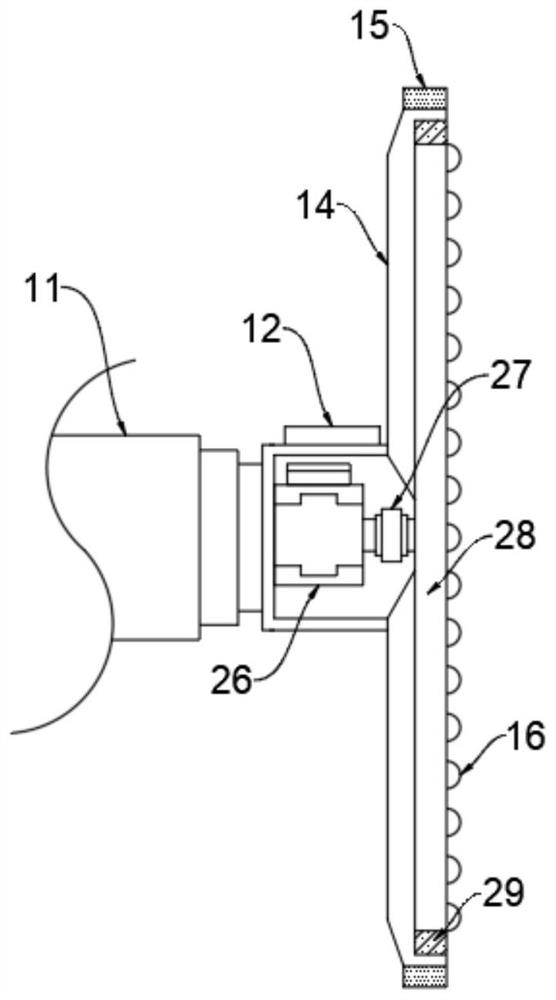

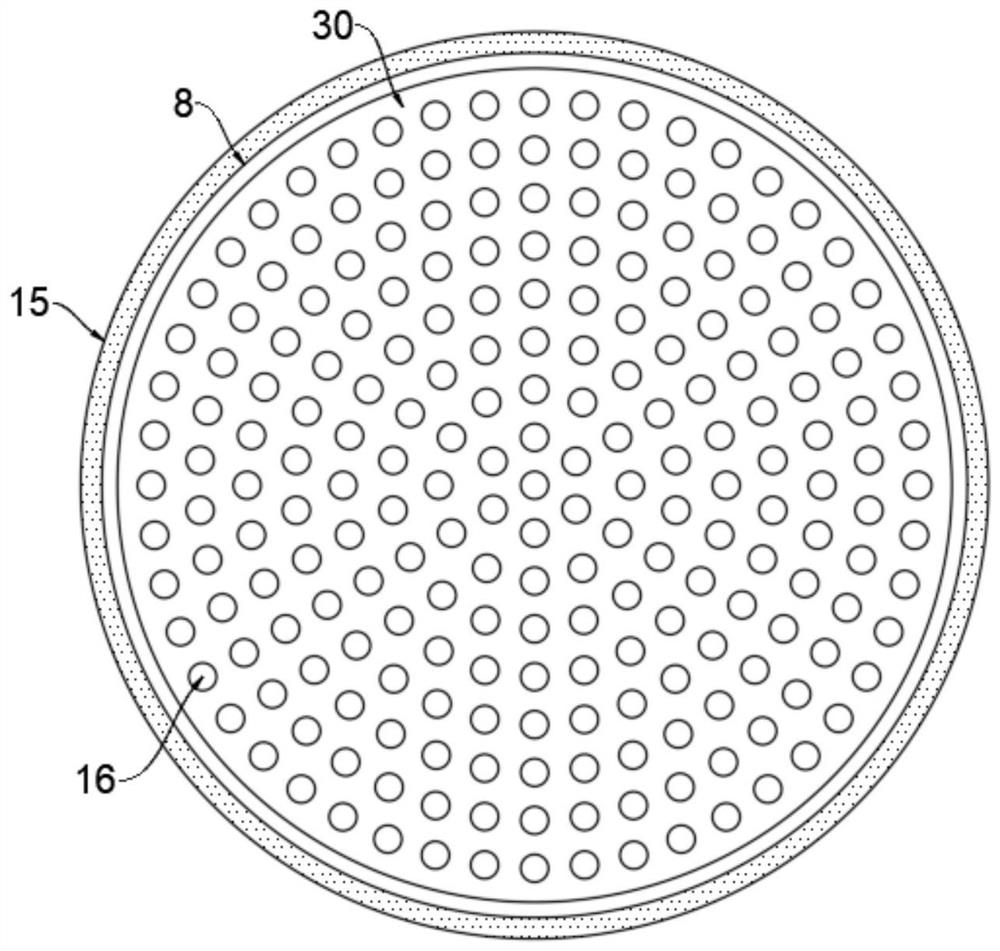

[0027] see Figure 1-6 , a kind of embodiment that the present invention provides: a kind of multi-functional nuclear fruit pressing juice production equipment, comprises juice extraction equipment main body 1, the inside of juice extraction equipment main body 1 is provided with storage pool 35, and one end of storage pool 35 is provided with The waste material cleaning port 2, the lower surface of the juicing equipment main body 1 is provided with a drain tank 22, and the joint between the drain tank 22 and the juice extracting equipment main body 1 is provided with a sieve hole 36, and several sieve holes 36 are provided with a plurality of drain holes. The lower end

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap