Combined land preparation machine

A soil leveling machine and soil leveling technology, which is applied to agricultural machinery and implements, shovels, plows, etc., can solve the problems of inconvenient adjustment of the angle of the rake blades, and achieve the effects of stable and convenient adjustment, good soil leveling effect and compact structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

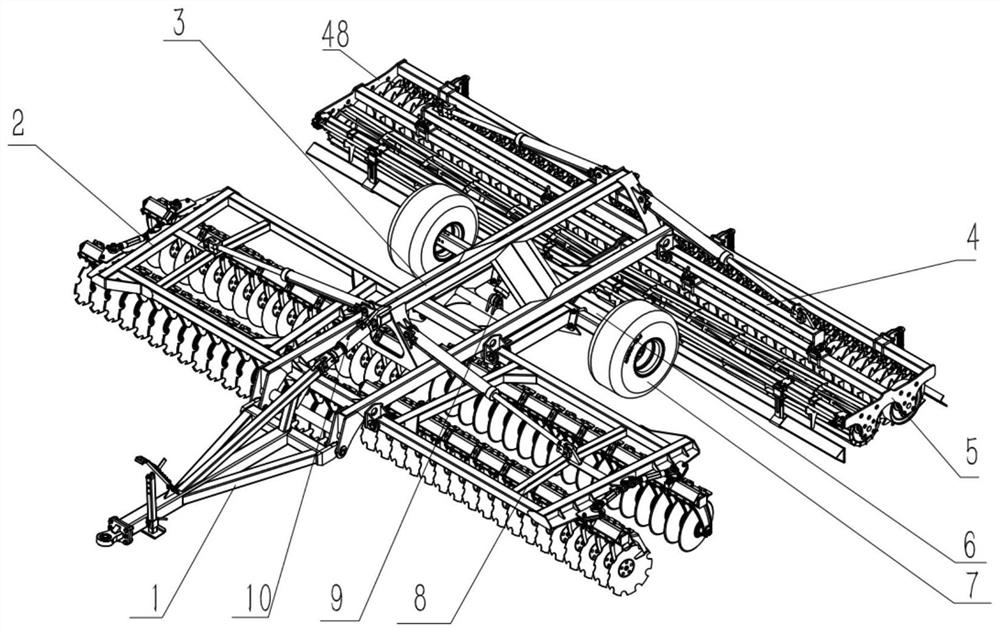

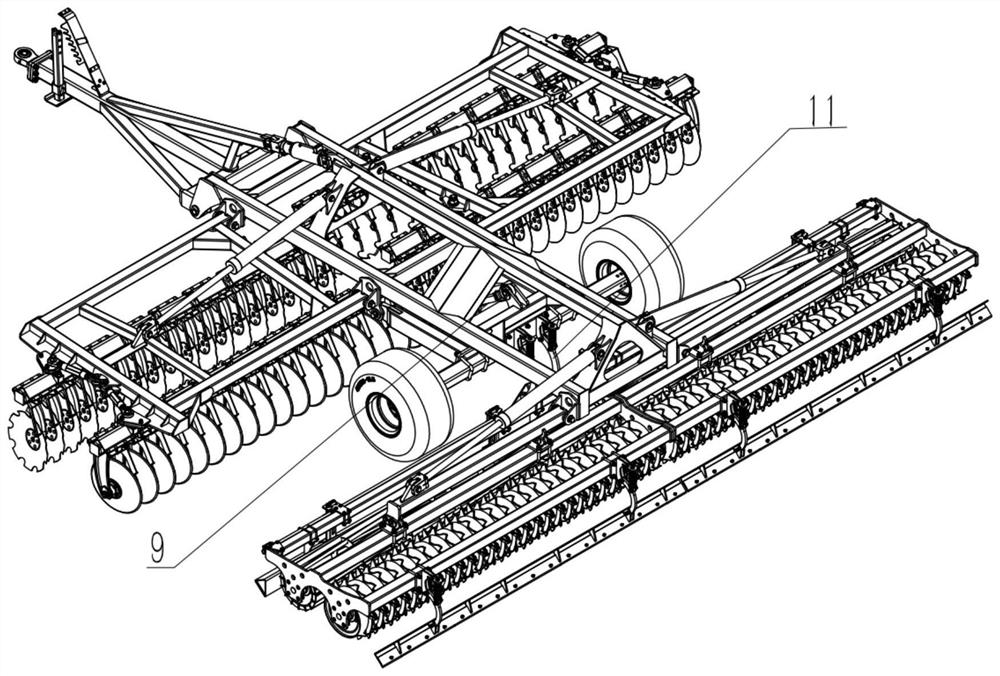

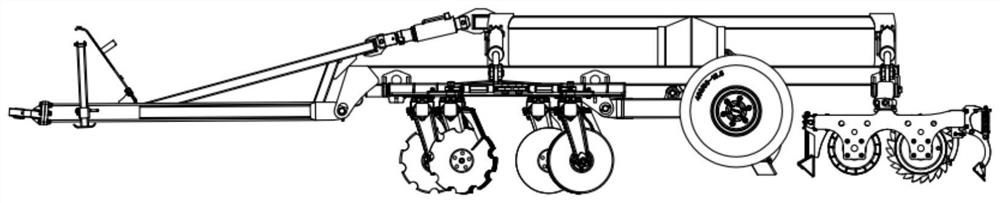

[0042] refer to Figure 1~Figure 3 , a combined land preparation machine, including a main rake frame 3, a rake group, a packer leveling device, a traction frame 1 and a traveling wheel 7; the rake group includes a left rake group 8 and a right rake group 2, and the packer is flat The soil device includes a left packer leveling assembly 5 and a right packer leveling assembly 48, the rake angles on the left rake group 8 and the right rake group 2 can be adjusted, and the left rake group 8 and the right rake group 2 is connected to the left and right sides of the main rake frame 3 in a foldable manner; Side; the front end of the main rake frame 3 is provided with a traction frame 1, and the rake group is located in front of the packer leveling device; the walking wheel shaft 6 is connected to the main rake frame 3 in a stowable manner. In the transportation state, the road wheels 7 are on the ground, and in the working state, the road wheels 7 are off the ground to ensure the oper

Embodiment 2

[0060] On the basis of Embodiment 1, the rear end of the traction frame 1 is flexibly connected to the main rake frame 3, and the front end of the traction frame 1 is connected to the main rake frame 3 through an oil cylinder with an adjustable stroke. When the tractor is pulling behind, adjust the best pulling point position of the main rake frame.

Embodiment 3

[0062] On the basis of Embodiment 1, the left rake group and the right rake group are connected to the left and right sides of the main rake frame 3 through folding oil cylinders, and the left packer leveling assembly and the right packer leveling assembly It is connected to the left and right sides of the main rake frame 3 through a folding oil cylinder, and the folding oil cylinder is connected with an overload protection hydraulic system, and the overload protection hydraulic system includes an accumulator. When the soil component encounters steep slopes, mounds of soil, or encounters bumps during transportation, the oil cylinder shrinks instantly and the pressure is too large, and the accumulator will prevent the oil cylinder from overloading and increase the service life of the oil cylinder. At the same time, the profiling effect can be achieved in the cultivation process, which can make the cultivation coverage wider and reduce the missing tillage rate of the cultivation lan

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap