Concrete pavement apparent damage repairing and efficient curing material and preparation method thereof

A technology for pavement appearance and damage repair, applied in solid waste management, sustainable waste treatment, climate sustainability, etc. The effect of quickly repairing cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

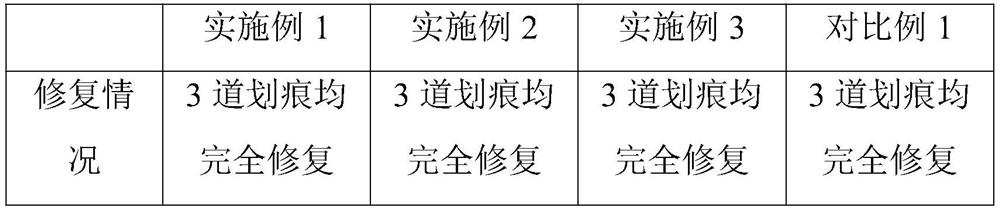

Examples

Embodiment 1

[0035] (1) Preparation of efficient solidified microcapsules: Add 10 parts of urea, 0.25 parts of ammonium chloride and 5 parts of sodium silicate to 30 parts of water, stir well to obtain the water phase; add 2 parts of oleic acid to 20 parts of Alkalophilic Bacillus subtilis spore powder and 3 parts of calcium lactate, stirred evenly, then added dropwise to the water phase, stirring at the same time during the dropping process, the stirring speed was 300rpm, to obtain an O / W emulsion, added 10 parts of formaldehyde, and reacted After 5 hours, filter, wash with distilled water, and dry naturally to obtain high-efficiency solidified microcapsules.

[0036] (2) Repair of apparent damage of concrete pavement and preparation of high-efficiency curing materials: take 300 parts of 42.5R ordinary Portland cement, 850 parts of gravel (coarse aggregate) with a particle size of ≤25mm, and river sand with a particle size of ≤2.5mm (fine aggregate) 500 parts, 90 parts of steel fiber with a

Embodiment 2

[0038] (1) Preparation of efficient solidified microcapsules: Add 10 parts of urea, 0.25 parts of ammonium chloride and 4 parts of sodium silicate to 30 parts of water, stir well to obtain the water phase; add 2 parts of oleic acid to 20 parts of Alkalophilic Bacillus coli spore powder and 4 parts of calcium lactate, stirred evenly, then added dropwise to the water phase, stirring at the same time during the dropping process, the stirring speed was 300rpm, to obtain an O / W emulsion, adding 10 parts of formaldehyde, React for 4 hours, filter, wash with distilled water, and dry naturally to obtain highly effective solidified microcapsules.

[0039] (2) Repair of apparent damage of concrete pavement and preparation of high-efficiency curing materials: Take 350 parts of 42.5R fly ash Portland cement, 800 parts of crushed stone (coarse aggregate) with a particle size of ≤25mm, and a particle size of ≤2.5 550 parts of river sand (fine aggregate), 100 parts of steel fiber with a lengt

Embodiment 3

[0041] (1) Preparation of high-efficiency solidified microcapsules: add 10 parts of urea, 0.25 parts of ammonium chloride and 2.5 parts of sodium silicate to 30 parts of water, stir well to obtain the water phase; add 2.5 parts of oleic acid to 20 parts Alkalophilic Bacillus Pasteurella spore powder and 5 parts of calcium lactate, stirred evenly, and then added dropwise to the water phase, stirring at the same time during the dropping process, the stirring speed was 300rpm, to obtain an O / W emulsion, adding 10 parts of formaldehyde, React for 5 hours, filter, wash with distilled water, and dry naturally to obtain high-efficiency solidified microcapsules.

[0042] (2) Repair of apparent damage of concrete pavement and preparation of high-efficiency curing materials: take 330 parts of 42.5R slag Portland cement, 900 parts of crushed stone (coarse aggregate) with a particle size of ≤25mm, and river sand with a particle size of ≤2.5mm (fine aggregate) 600 parts, 80 parts of steel f

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap