Bacterial cellulose modified Bucky paper as well as preparation method and application thereof

A technology of bacterial cellulose and bucky paper, applied in the field of bacterial cellulose modified bucky paper and its preparation, can solve problems such as poor flexibility and limitations, achieve improved mechanical properties, easy large-scale manufacturing, and simple preparation methods Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

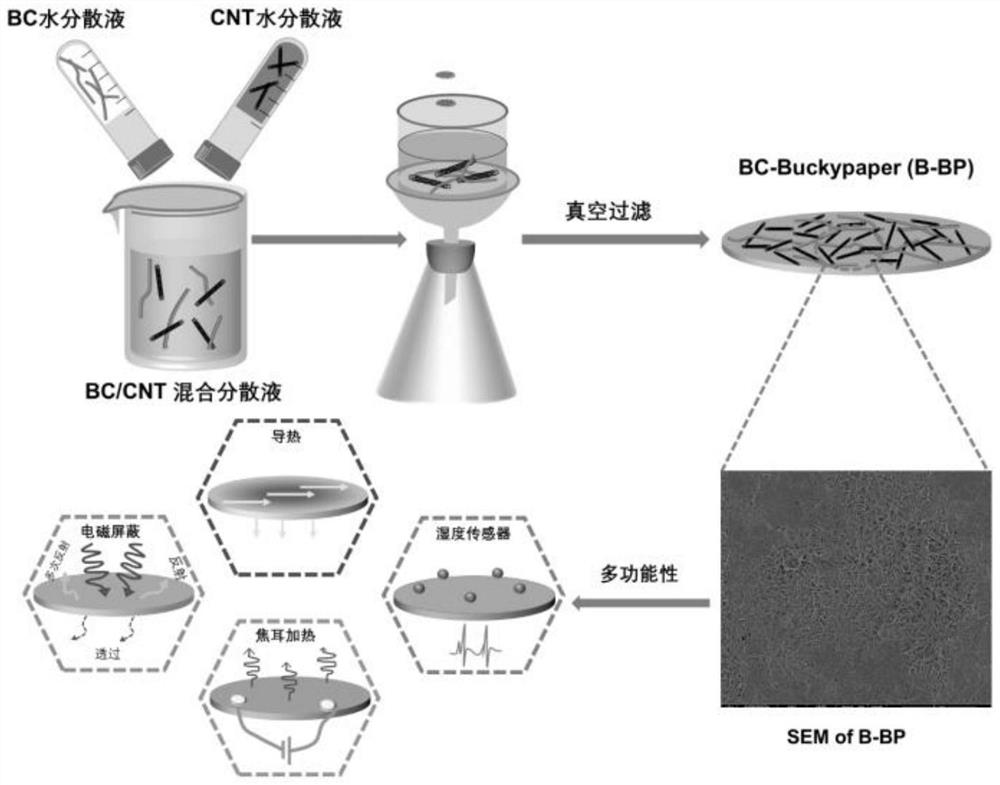

[0031] The invention provides a kind of preparation method of bacterial cellulose modified bucky paper, comprising the following steps:

[0032] The bacterial cellulose aqueous dispersion and the carbon nanotube aqueous dispersion are mixed for modification to obtain bacterial cellulose modified bucky paper.

[0033] In the present invention, unless otherwise specified, the required preparation materials are commercially available products well known to those skilled in the art.

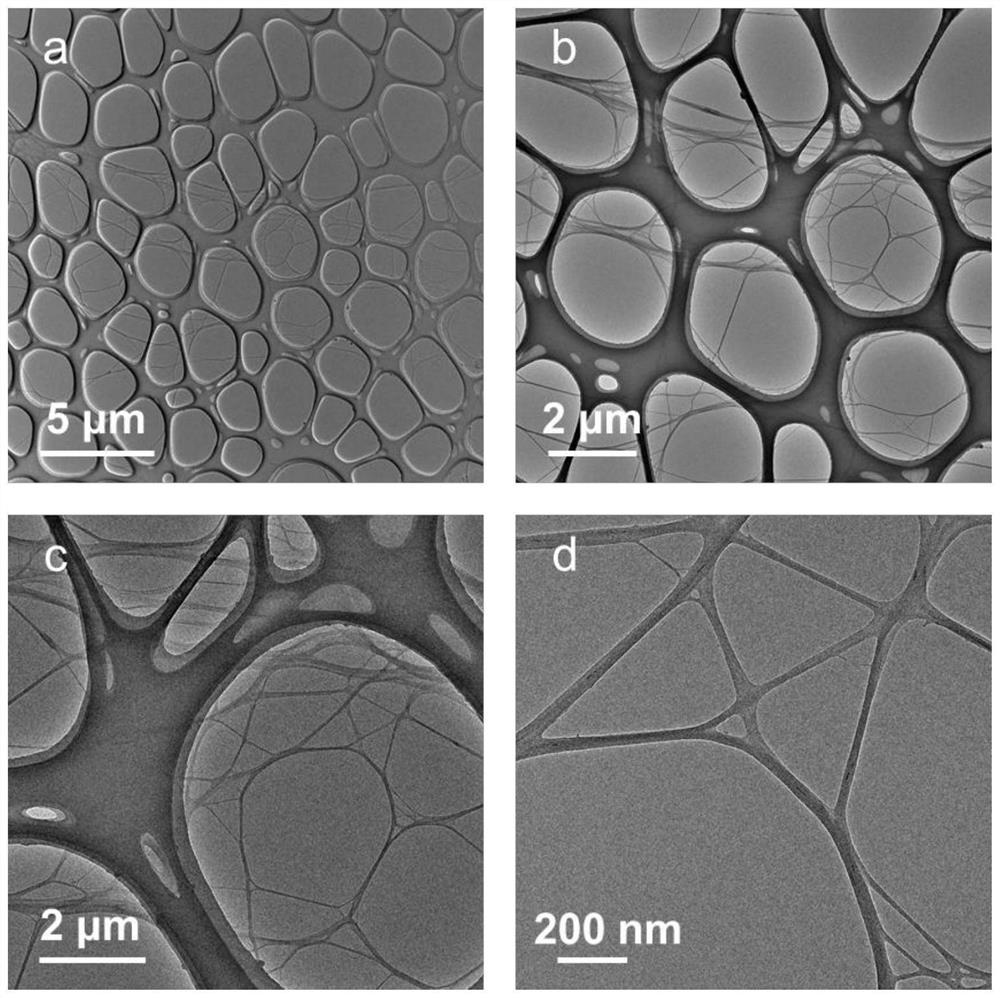

[0034] In the present invention, the diameter of the bacterial cellulose (BC) in the bacterial cellulose aqueous dispersion is preferably 50-100 nm, and the length is preferably 20-200 μm; the present invention has no special limitation on the source of the bacterial cellulose, Commercially available products well known in the art can be used. In the embodiment of the present invention, the solid content of the bacterial cellulose is 0.65 wt%.

[0035] In the present invention, the concentration of the

Embodiment 1

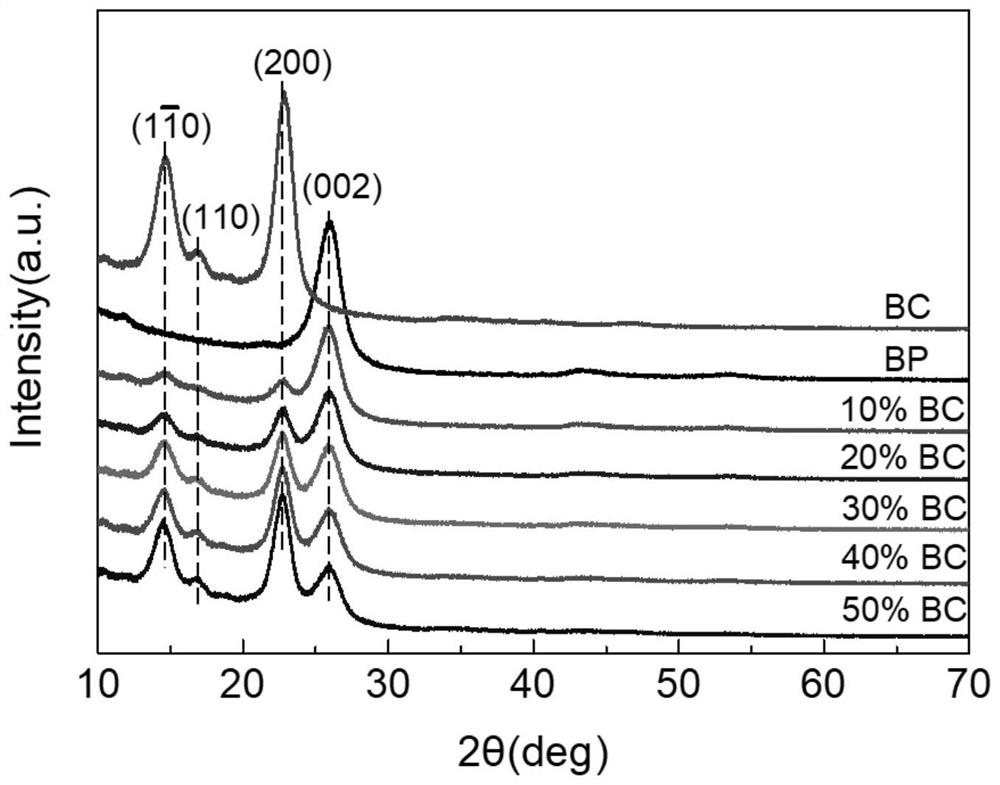

[0048] 5 mL bacterial cellulose aqueous dispersion (0.6 mg / mL) and 45 mL carbon nanotube aqueous dispersion (0.6 mg / mL) were stirred for 30 min, and the resulting blended solution was vacuum filtered through a mixed filter membrane with a pore size of 0.45 μm. The density is 0.1MPa. After washing the obtained bacterial cellulose modified bucky paper sheet with excess deionized water, soak it in an acetone bath for several times to remove the mixed filter membrane. After drying, the bacterial cellulose modified bucky paper B- BP, with a thickness of 35 μm, is recorded as 10% BC.

Embodiment 2

[0050] The difference between this embodiment and embodiment 1 is only: 10mL bacterial cellulose aqueous dispersion (0.6mg / mL) and 40mL carbon nanotube aqueous dispersion (0.6mg / mL), others are the same as embodiment 1, thickness is 35 μ m, Recorded as 20% BC.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap