Natural gas pressure energy utilization system

A technology of pressure energy and natural gas, applied in pipeline systems, gas/liquid distribution and storage, steam engine installations, etc., can solve the problems of unsuitable natural gas pressure energy, inconvenience to reuse natural gas, mixed with air bubbles, etc., and achieve high power generation efficiency and structure. Simple, low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

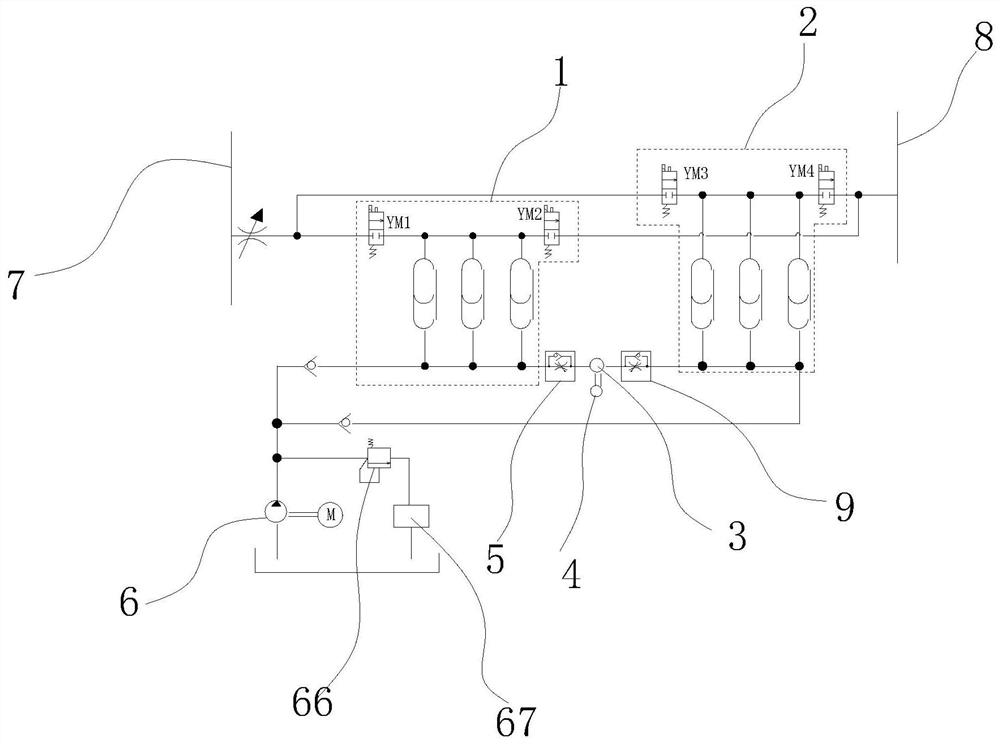

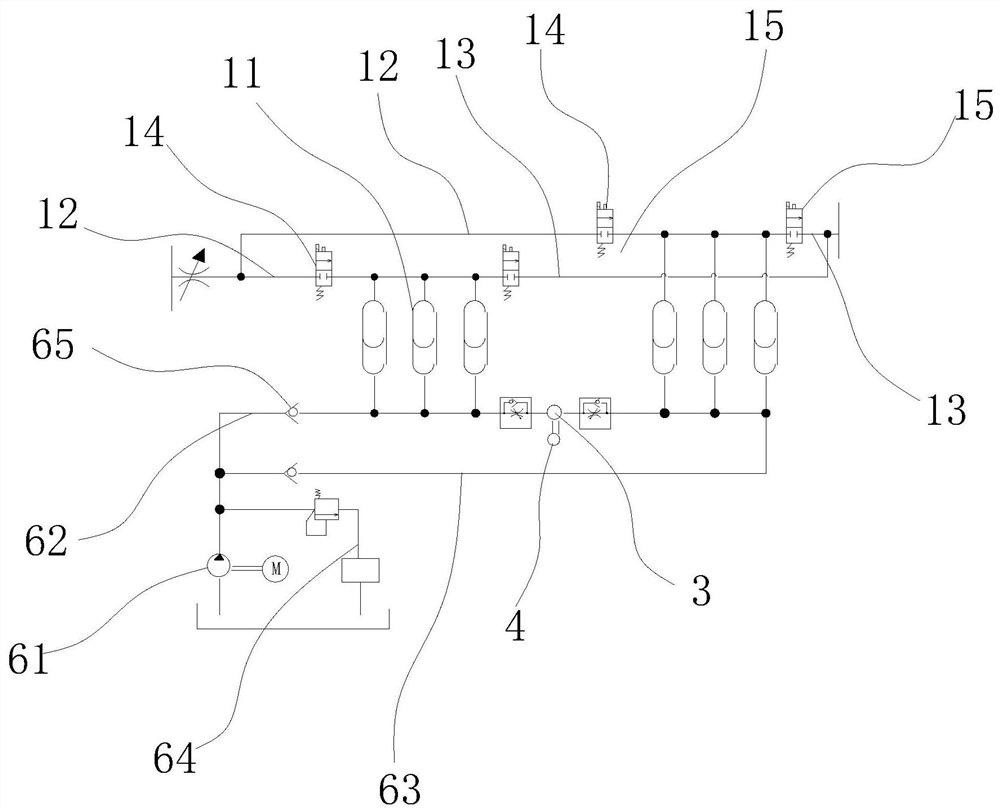

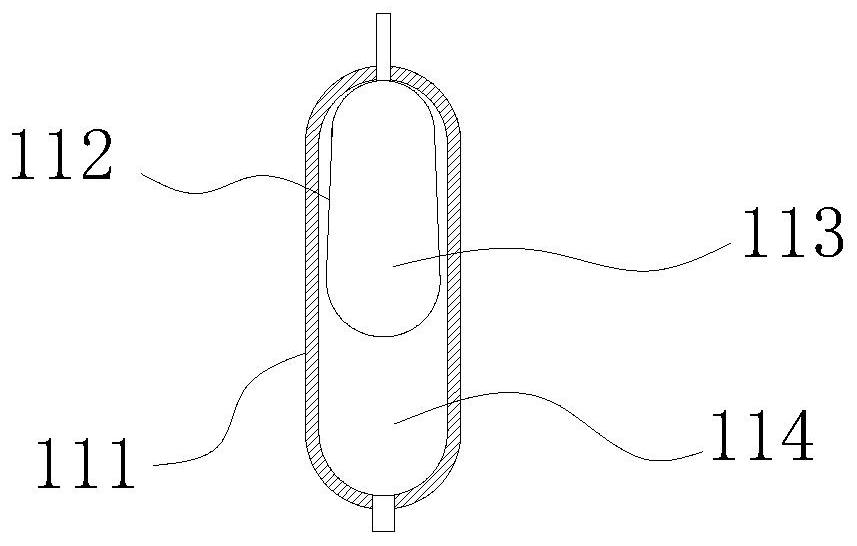

[0026] Such as Figure 1 to Figure 3 As shown, the natural gas pressure energy utilization system of the present invention includes a first pressure energy conversion unit 1 , a second pressure energy conversion unit 2 , a hydraulic transmission device 3 and a generator 4 . The first pressure energy conversion unit 1 and the second pressure energy conversion unit 2 respectively include pressure conversion components. The pressure conversion assembly includes an intake pipe 12 , an exhaust pipe 13 and at least one energy conversion device 11 . The energy conversion device 11 includes a casing 111 and a movable sealing structure 112, the movable sealing structure 112 is movably arranged in the casing 111, and divides the inner chamber of the casing 111 into a first medium chamber 114 and a second medium chamber 114. The medium chamber 113 can adjust the si

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap