Adaptive PID anaerobic fermentation temperature control system and method based on Elman neural network

A technology of temperature control system and temperature control method, which is applied in the direction of temperature control using electric methods, electric controllers, controllers with specific characteristics, etc., which can solve problems such as poor combustion control, low solar energy density, and large weather influence , to achieve the effects of ensuring stability and robustness, improving responsiveness, and strong time-varying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0036] Example 1

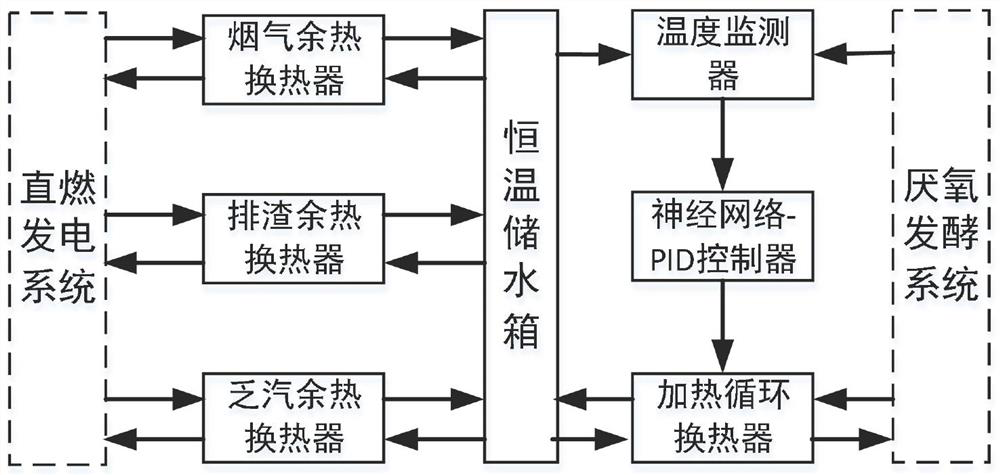

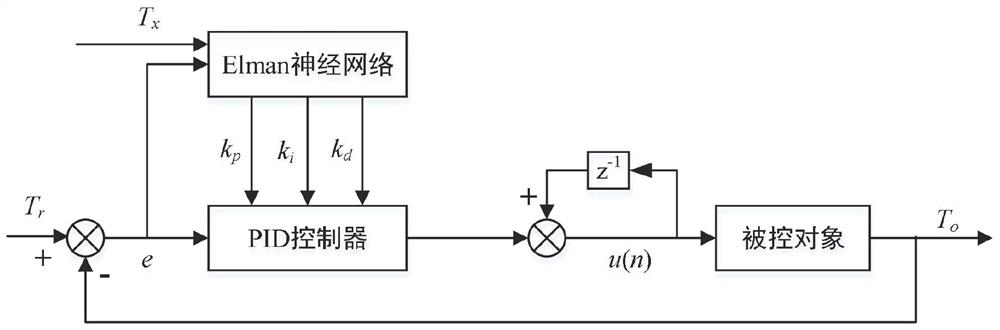

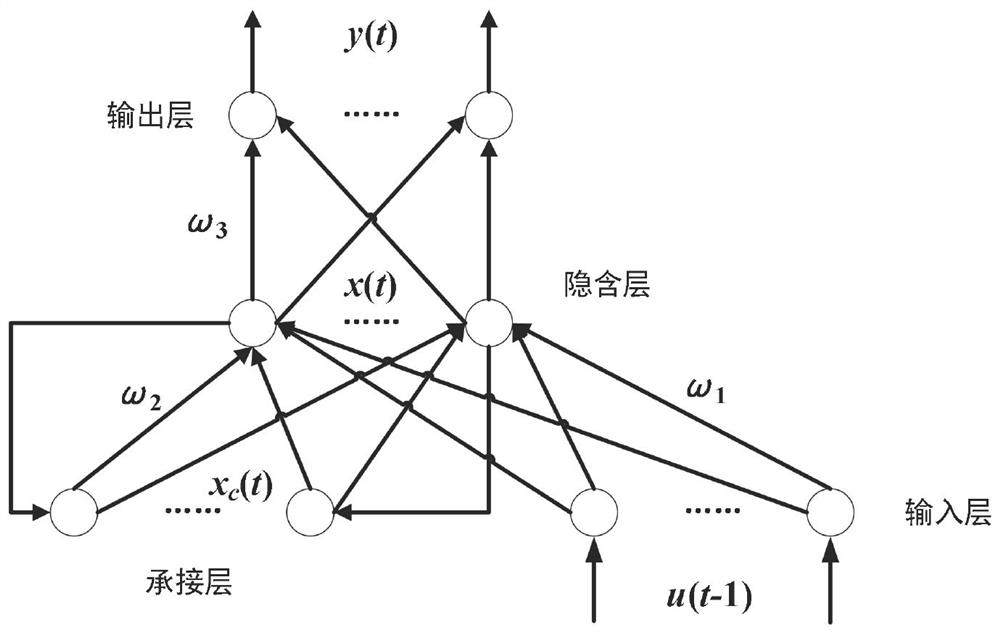

[0037] ELMAN-based neural network adaptive PID anaerobic fermentation temperature control system, such as figure 1As shown, including flue gas waste heat exchangers, slag residual heat heat exchangers, lap-saver heat exchangers, heating circulating heat exchanger, temperature monitor, constant temperature water storage tank, and neural network -PID controller; said smoke The remaining heat heat exchange unit is connected to the constant temperature storage tank, and the smoke heat heating circulating water of the direct-fired power generation system is recovered to the constant temperature storage tank; the slag residual heat heat exchange is connected to the constant temperature storage tank and recovered direct-fire power generation. The slag heat heating circulating water is sent to a constant temperature storage tank; the lapse of the steam is connected to the constant temperature storage tank, recovering the lack of fire-fuel power generation system to the con

Example Embodiment

[0052] Example 2

[0053] ELMAN-based neural network adaptive PID anaerobic fermentation temperature control system, such as figure 1 As shown, including flue gas waste heat exchangers, slag residual heat heat exchangers, lap-saver heat exchangers, heating circulating heat exchanger, temperature monitor, constant temperature water storage tank, and neural network -PID controller; said smoke The remaining heat heat exchange unit is connected to the constant temperature storage tank, and the smoke heat heating circulating water of the direct-fired power generation system is recovered to the constant temperature storage tank; the slag residual heat heat exchange is connected to the constant temperature storage tank and recovered direct-fire power generation. The slag heat heating circulating water is sent to a constant temperature storage tank; the lapse of the steam is connected to the constant temperature storage tank, recovering the lack of fire-fuel power generation system to the co

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap