Flame-retardant environment-friendly damping expansion glue for vehicles and preparation method thereof

An environmentally friendly and automotive-used technology, which is applied in the field of expansion rubber, can solve the problems of low stability of colloidal mechanical properties, excessive use of flame retardants in flame-retardant expansion rubber, etc., and achieve the effect of uniform product structure, low price and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] The present invention also provides a method for preparing a flame-retardant, environment-friendly, shock-absorbing and expanding rubber for vehicles, comprising the following steps:

[0047] (1) mixing the solid rubber with 1 / 3 of the softening agent and masticating to obtain the masticated solid rubber;

[0048] (2) Vacuum knead the solid rubber, liquid rubber, hygroscopic agent, foaming agent, flame retardant, stabilizer, filler, vulcanizing agent, smoke-mimicking synergist and remaining softener after mastication for 1 to 2 hours, and then add The curing agent and the tackifier are vacuum kneaded for 1 to 2 hours to obtain a flame-retardant, environment-friendly, shock-absorbing and expanding adhesive for vehicles.

[0049] In the present invention, the temperature of step (1) mastication is preferably 20-45°C, more preferably 22-42°C, more preferably 35°C; the time of mastication is preferably 0.5-1.5h, more preferably 0.6- 1.2h, more preferably 1.1h.

[0050] In

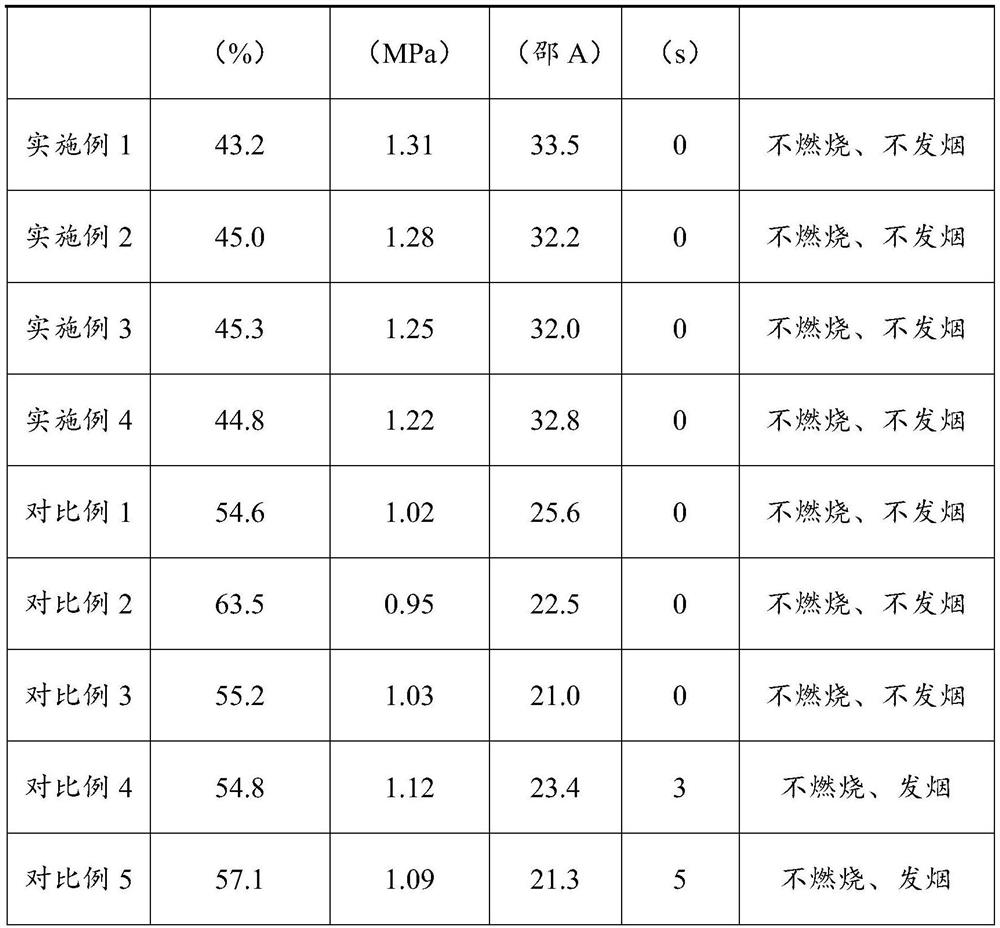

Embodiment 1

[0056] The flame-retardant, environment-friendly and shock-absorbing expansion rubber for vehicles in this embodiment is prepared from raw materials containing the following parts by mass:

[0057] 15 parts of styrene-butadiene rubber, 30 parts of polybutadiene liquid rubber, 23 parts of epoxy resin, 6 parts of DPHP, 1.5 parts of p-diphenylmethane bis(N,N-dimethyl)urea curing agent, polyurethane foam 1 part of calcium oxide, 15 parts of aluminum hydroxide, 5 parts of zinc molybdate, 1.5 parts of calcium zinc stabilizer, 13 parts of nano-calcium carbonate, and 2 parts of dicumyl peroxide.

[0058] Its preparation method comprises the following steps:

[0059] (1) Mix styrene-butadiene rubber with 1 / 3 of DPHP, and masticate at 22°C for 1 hour to obtain masticated styrene-butadiene rubber;

[0060] (2) Styrene butadiene rubber, polybutadiene liquid rubber, calcium oxide, polyurethane foaming agent, aluminum hydroxide, zinc molybdate, calcium zinc stabilizer, nano calcium carbonat

Embodiment 2

[0062] The flame-retardant, environment-friendly and shock-absorbing expansion rubber for vehicles in this embodiment is prepared from raw materials containing the following parts by mass:

[0063] 5 parts of polybutadiene rubber, 10 parts of nitrile rubber, 10 parts of liquid silicone rubber, 20 parts of polybutadiene liquid rubber, 25 parts of phenolic resin, 8 parts of paraffin oil, 4,4-diaminodiphenyl sulfone curing agent 1 part, 3 parts of azodicarbonamide, 10 parts of aluminum oxide, 10 parts of resorcinol tetrakis (2,6-xylyl) diphosphate flame retardant, 10 parts of zinc borate, 2 parts of zinc stearate , 8 parts of talcum powder, 4 parts of mica powder, and 1.2 parts of sulfur.

[0064] Its preparation method comprises the following steps:

[0065] (1) Mix polybutadiene rubber, nitrile rubber and one third of paraffin oil, and masticate at 25°C for 1.2h to obtain solid rubber after mastication;

[0066] (2) The plasticized solid rubber, liquid silicone rubber, polybutad

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap