Preparation method and application of puncture-proof flexible material

A flexible material, polyethylene technology, applied in the field of stab-proof clothing, can solve the problems of poor comfort and poor stab-proof effect, and achieve the effect of high cost performance, good protection performance and reasonable price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

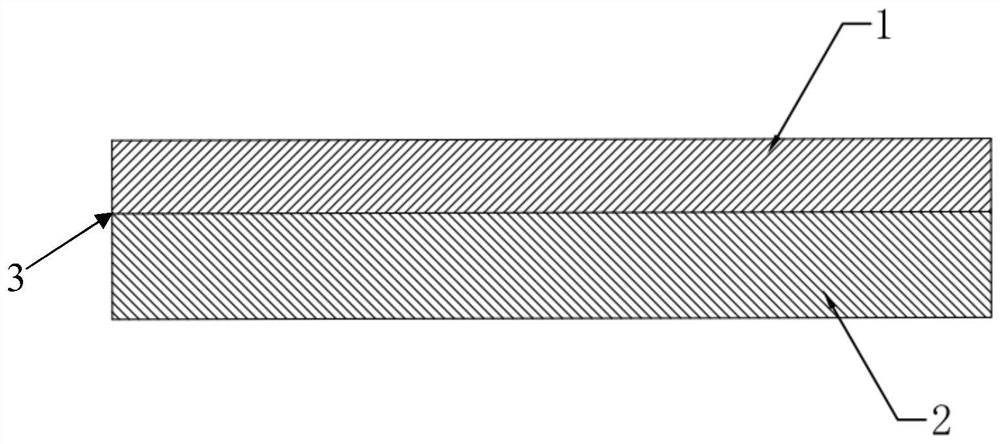

Image

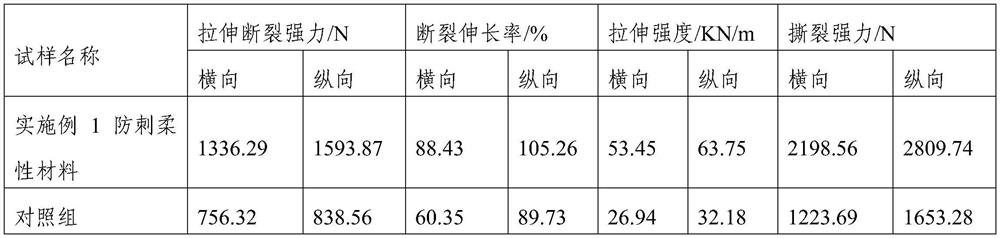

Examples

Embodiment 1

[0028] This embodiment provides a method for preparing a stab-proof flexible material, which includes the following steps:

[0029] Step 1, preparation of polyethylene mixture cloth layer

[0030] The polyethylene mixture cloth layer is made of ultra-high molecular weight polyethylene short fibers and viscose fibers. The elongation rate is 17-20%.

[0031] The density of UHMWPE staple fiber is 0.97~0.98g / cm 3 , the strength is 2.8-4N / tex, the modulus is 91-140N / tex, and the elongation is 3.5%-3.7%.

[0032] Firstly, the ultra-high molecular weight polyethylene staple fibers are opened, carded, and then formed into a web. In the process of web forming, in order to avoid static entanglement and electrostatic knot phenomenon of ultra-high molecular weight polyethylene staple fibers in the web-laying process, it is necessary to combine viscose fibers and ultra-high molecular weight Polyethylene short fibers are mixed together and transported to form a net. During the proces

Embodiment 2

[0042] This embodiment provides a method for preparing a stab-proof flexible material, which includes the following steps:

[0043] Step 1, preparation of polyethylene mixture cloth layer

[0044]The polyethylene mixture cloth layer is made of ultra-high molecular weight polyethylene short fibers and viscose fibers. The elongation rate is 17-20%. The density of UHMWPE staple fiber is 0.97~0.98g / cm 3 , the strength is 2.8-4N / tex, the modulus is 91-140N / tex, and the elongation is 3.5%-3.7%.

[0045] Firstly, the ultra-high molecular weight polyethylene staple fiber is opened, carded, and then formed into a web. In the process of web forming, in order to avoid static entanglement and electrostatic knot phenomenon of ultra-high molecular weight polyethylene staple fibers in the web-laying process, it is necessary to combine viscose fibers and ultra-high molecular weight Polyethylene short fibers are mixed together and transported to form a net. During the process of forming

Embodiment 3

[0055] This embodiment provides a method for preparing a stab-proof flexible material, which includes the following steps:

[0056] Step 1, preparation of polyethylene mixture cloth layer

[0057] The polyethylene mixture cloth layer is made of ultra-high molecular weight polyethylene short fibers and viscose fibers. The elongation rate is 17-20%. The density of UHMWPE staple fiber is 0.97~0.98g / cm 3 , the strength is 2.8-4N / tex, the modulus is 91-140N / tex, and the elongation is 3.5%-3.7%. The density of UHMWPE staple fiber is 0.97~0.98g / cm 3 , the strength is 2.8-4N / tex, the modulus is 91-140N / tex, and the elongation is 3.5%-3.7%.

[0058] Firstly, the ultra-high molecular weight polyethylene staple fibers are opened, carded, and then formed into a web. In the process of web forming, in order to avoid static entanglement and electrostatic knot phenomenon of ultra-high molecular weight polyethylene staple fibers in the web-laying process, it is necessary to combi

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap