Machine tool management device for numerical control machine tool

A tool management and CNC machine tool technology, which is applied in the direction of manufacturing tools, metal processing machinery parts, metal processing equipment, etc., can solve the problems of laborious picking and placing operations, low intelligence, and more than one tool, and achieve labor-saving picking and placing operations. High degree of intelligence, easy to adjust the effect of lifting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment

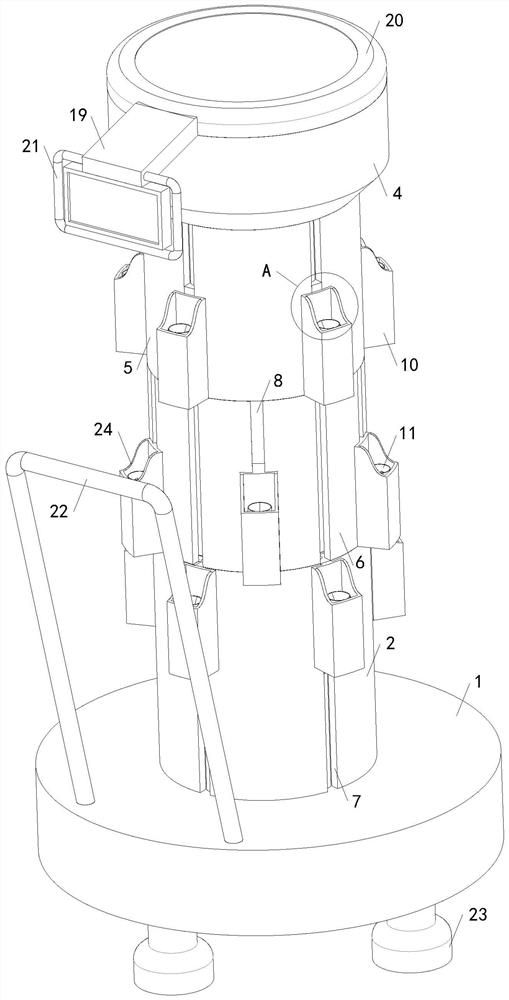

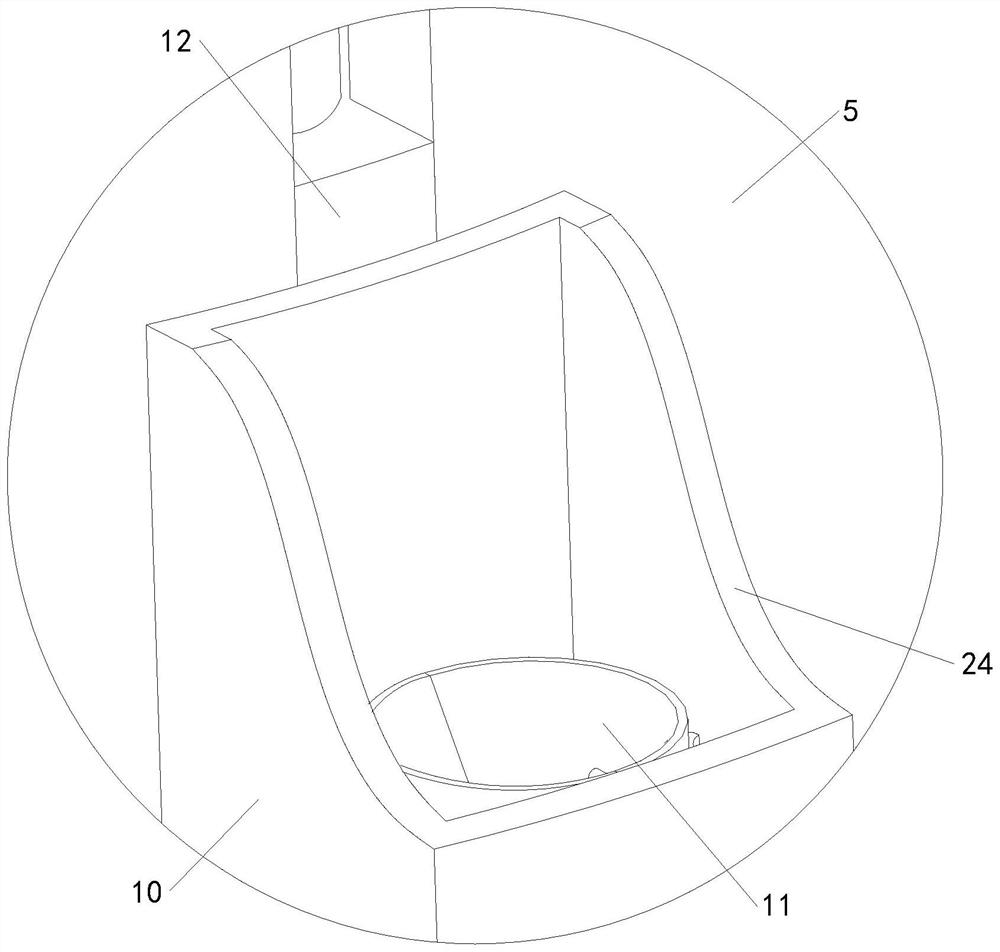

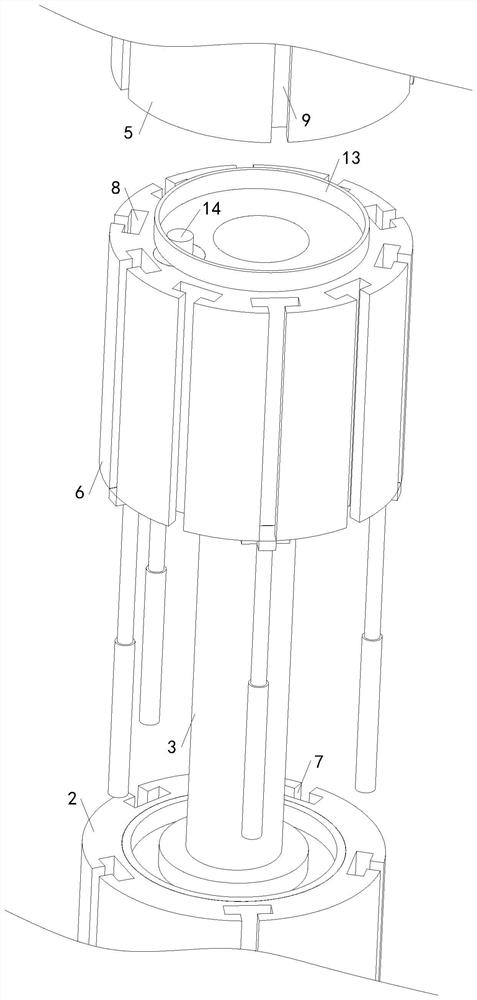

[0029] see Figure 1-6 , a machine tool management device for a CNC machine tool, comprising a base 1, a base connecting frame 2 and a stem 3, a push handle 22 is installed on the top of the base 1, a leg 23 is installed on the bottom of the base 1, and the inside of the leg 23 is Universal wheels with electric drive lifting function are installed, the base connecting frame 2 and the stem 3 are fixedly connected to the top of the base 1, and the top of the stem 3 extends through the base connecting frame 2 to the top of the base connecting frame 2 , the top of the stem 3 is fixedly connected with a top mounting frame 4, the bottom of the top mounting frame 4 is rotatably connected with a secondary connecting frame 5, the bottom end of the secondary connecting frame 5 is rotatably connected with a primary connecting frame 6, and the primary connecting frame 6 is rotationally connected with the basic connecting frame 2, and a servo drive system is provided between the primary conne

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap