Method for removing tetracycline antibiotics in landfill leachate

A technology of landfill leachate and tetracyclines, which is applied in the field of removal of tetracycline antibiotics in landfill leachate, can solve the problem of low removal efficiency of tetracycline antibiotics, and achieve the effects of improved treatment effect, high removal rate, and low pyrolysis temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0031] Example 1:

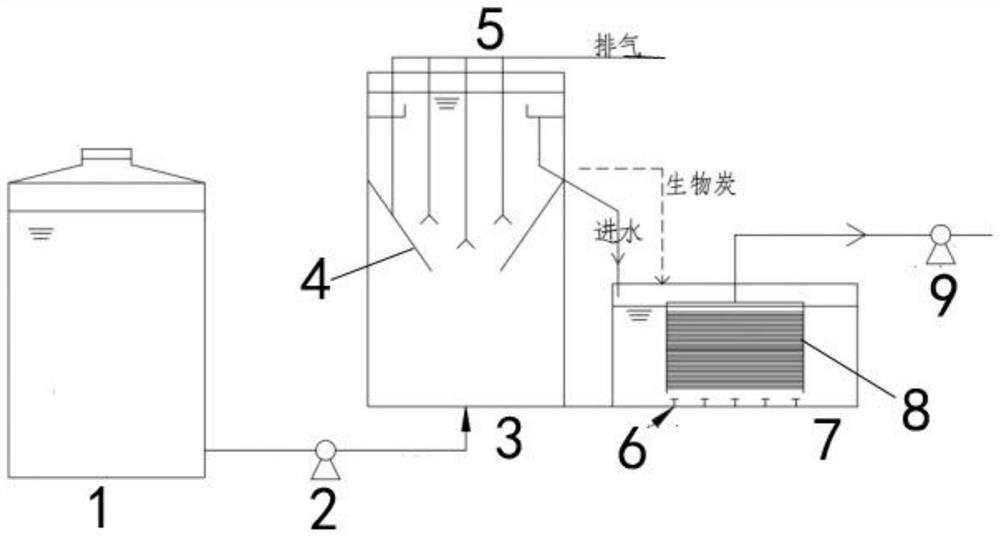

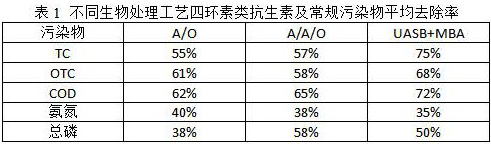

[0032] Comparison and optimization of degradation and removal effects of landfill leachate by analyzing three biological treatment processes (A / O, A / A / O and UASB+MBA):

[0033] A) Removal rate of tetracycline antibiotics under different biological treatment process conditions

[0034] A / O treatment process: A / O reactor consists of an 8L anaerobic tank (A), a 24L aerobic tank (O) and a 25L sedimentation tank. When the landfill leachate is degraded, the landfill leachate flows through the 8L anaerobic tank (A), the 24L aerobic tank (O) and the 25L sedimentation tank in sequence. The sludge at the bottom of the sedimentation tank is returned to the anaerobic tank by the peristaltic pump, and the reflux ratio is 60% to 100%; the mixed solution is returned from the aerobic tank to the anaerobic tank by the peristaltic pump, and the reflux ratio is 100% to 300%. The sludge concentrations in the 8L anaerobic tank (A) and the 24L aerobic tank (O) were both

Example Embodiment

[0048] Example 2

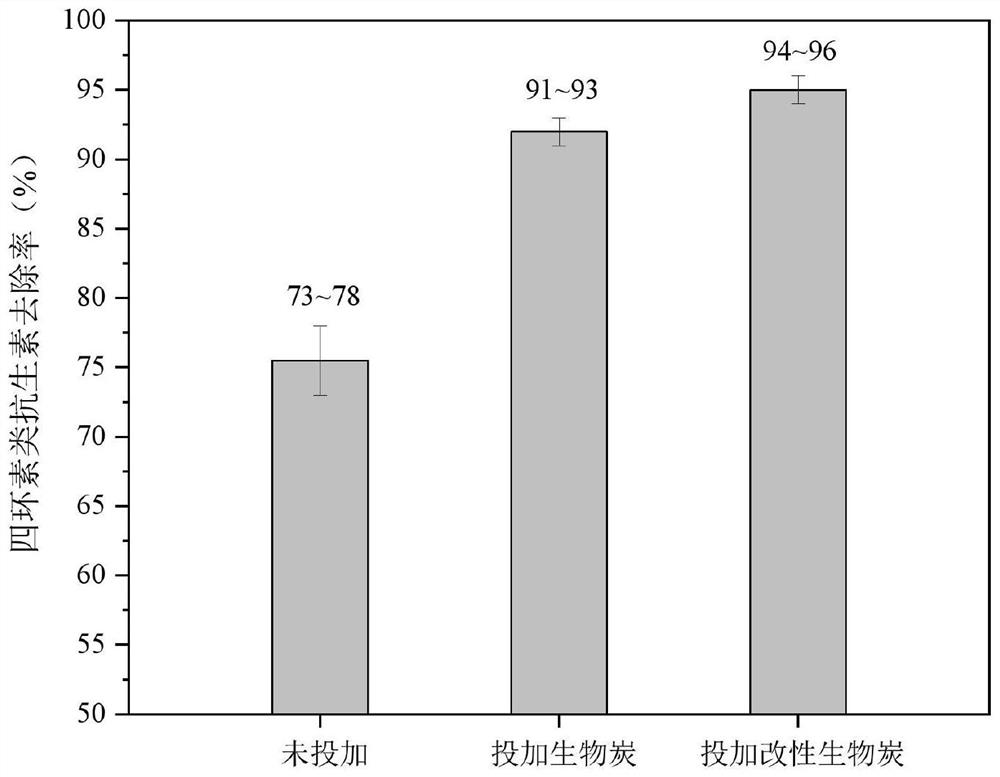

[0049] Carry out the preparation and dosing of biochar under the optimal process condition set in embodiment 1

[0050] A preparation of biochar

[0051] Rice straw, the raw material for biochar preparation, was taken from a farmland in Zhejiang Province. The collected rice stalks were washed with water, dried and crushed through an 80-mesh sieve for later use. Biochar was prepared by high-temperature slow-speed pyrolysis method, that is, a certain amount of rice straw was weighed and placed in a closed high-pressure reactor for hydrothermal carbonization treatment. o The C / min was raised to 600°C and maintained for 2 hours. After cooling to room temperature, it was washed with deionized water until neutral, dried in an oven at 60°C for 24 hours, and passed through a 100-mesh sieve to obtain rice straw biochar. The biochar has a pore size of 17.0nm and a specific surface area of 21.7m 2 / g.

[0052] B Dosing of biochar

[0053] Run the reactor under

Example Embodiment

[0057] Example 3

[0058] Carry out the preparation and dosing of modified biochar under the optimal process condition set in embodiment 1

[0059] A) Preparation of modified biochar:

[0060] Rice straw was washed and dried, crushed and passed through an 80-mesh sieve, and then biochar was prepared by high-temperature slow pyrolysis method, that is, a certain amount of rice straw was weighed and placed in a closed high-pressure reactor for hydrothermal carbonization. o C / min increased to 600 o C for 2 hours, after cooling to room temperature, wash with deionized water until neutral, and dry in an oven at 60°C for 24 hours before use. Prepare 1mol / L of KH 2 PO 4 solution, with a mass ratio of 2:1 (KH 2 PO 4 : biological charcoal) was added to reserve biochar, stirred for 2h and then suction filtered, at 100 o C dried in an oven for 10 h and passed through a 100-mesh sieve to obtain modified biochar. The modified biochar has a pore size of 21.2nm and a specific surface

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap