Method for preparing N-acetyl-L-tyrosine

A technology of tyrosine and acetyl, applied in the field of preparing N-acetyl-L-tyrosine, which can solve the problems of high substance content, high production cost, and large energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

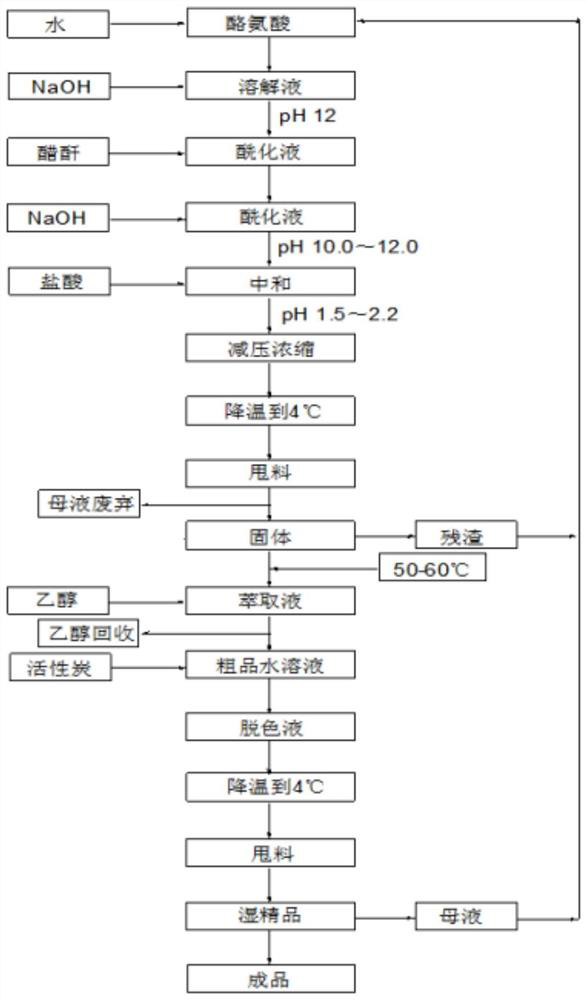

[0036] In this example, N-acetyl-L-tyrosine was prepared according to the following steps, and the process flow diagram is shown in figure 1 :

[0037] Step 1. Disperse 100 g of L-tyrosine in 200 ml of water, stir quickly to avoid agglomeration.

[0038] Step 2. Add 30% sodium hydroxide solution dropwise until the L-tyrosine is completely dissolved, pH=12.05.

[0039] Step 3. Add 59.2 g (1.05 times the molar amount) of acetic anhydride dropwise for 30 minutes, while adding 30% sodium hydroxide solution dropwise to maintain the pH between 8 and 10.

[0040] Step 4. After adding acetic anhydride, dropwise add sodium hydroxide solution to adjust pH=11.50, and keep the temperature at 60°C for 20 minutes.

[0041] Step 5. Add industrial hydrochloric acid to adjust the pH of the solution to 1.72.

[0042] Step 6, control the vacuum to be above 0.08MP, and concentrate under reduced pressure at 80°C until the reaction solution is basically in a solid state.

[0043] Step 7, after bei

Embodiment 2

[0050] In this example, N-acetyl-L-tyrosine was prepared as follows:

[0051] Step 1. Disperse 500 grams of L-tyrosine in 1 liter of water and stir quickly to avoid agglomeration.

[0052] Step 2. Add 30% sodium hydroxide solution dropwise until the L-tyrosine is completely dissolved, pH=11.80.

[0053] Step 3. Add 296.3 g (1.05 times the molar amount) of acetic anhydride dropwise for 30 minutes, while adding 30% sodium hydroxide solution dropwise to maintain the pH between 8 and 10.

[0054] Step 4. After adding acetic anhydride, adjust pH=11.22 with sodium hydroxide solution, and keep the temperature at 60°C for 20 minutes.

[0055] Step 5. Add industrial hydrochloric acid to adjust the pH of the solution to 1.90.

[0056] Step 6, control the vacuum to be above 0.08MP, and concentrate under reduced pressure at 60-80°C until the reaction solution is basically in a solid state.

[0057] Step 7. After cooling to 4°C for full crystallization, the material is thrown away to obtai

Embodiment 3

[0063] In this example, N-acetyl-L-tyrosine was prepared as follows:

[0064] Step 1. Disperse 100 grams of L-tyrosine in 100 ml of water, stir quickly to avoid agglomeration.

[0065] Step 2. Put the high-quality mother liquor of Example 1 and the washed insoluble matter (L-tyrosine) into the reaction vessel together.

[0066] Step 3. Add 30% sodium hydroxide solution dropwise until L-tyrosine is completely dissolved, pH=12.25.

[0067] Step 4. Add 59.2 grams (1.05 times the molar amount) of acetic anhydride dropwise for 30 minutes, while adding 30% sodium hydroxide solution dropwise to maintain the pH between 8 and 10.

[0068] Step 5. After adding acetic anhydride, adjust pH=10.99 with sodium hydroxide solution, and keep the temperature at 60°C for 30 minutes.

[0069] Step 6, adding industrial hydrochloric acid to adjust the pH of the solution to 1.87.

[0070] Step 7, control the vacuum to be above 0.08MP, and concentrate under reduced pressure at 80°C until the reaction

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap