Automatic continuous net wrapping production equipment for rock wool composite board

A technology of production equipment and composite boards, applied in the direction of layered products, transportation and packaging, roller tables, etc., can solve the problems of no automatic production equipment, etc., achieve constant and fast finished product quality, improve production efficiency, and save manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, but not all of the embodiments. Based on the embodiments of the present invention, all other embodiments obtained by those of ordinary skill in the art without creative efforts shall fall within the protection scope of the present invention.

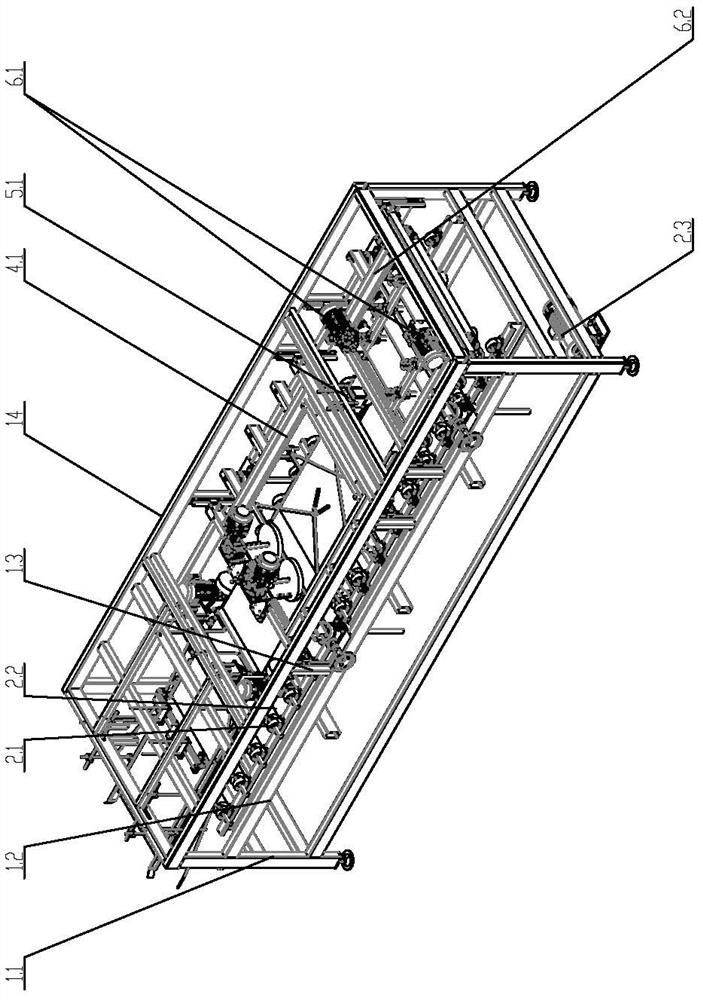

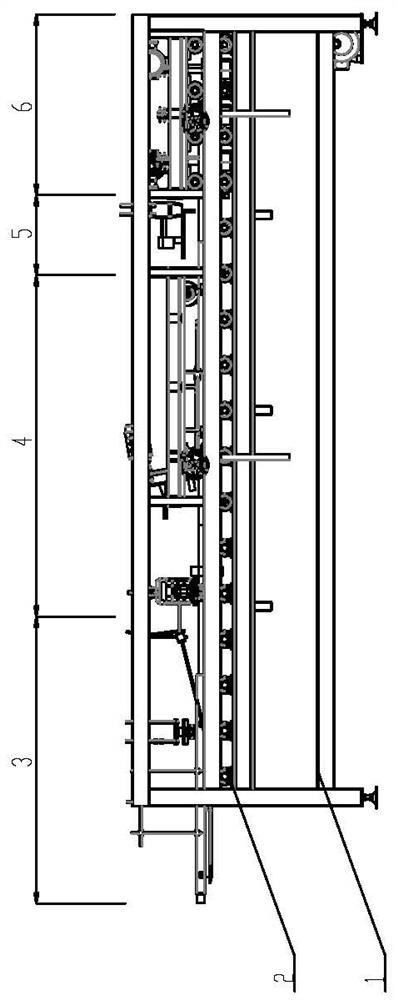

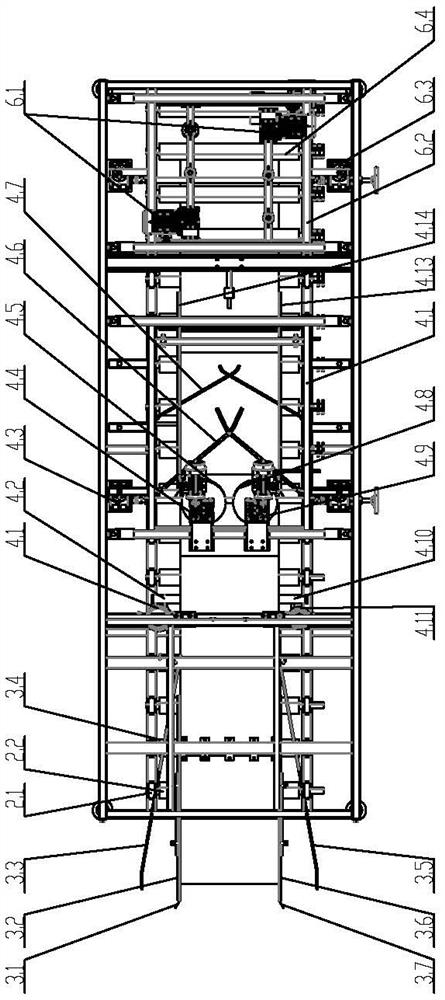

[0039] see Figure 1 to Figure 7 , The present invention provides a technical solution: an automatic continuous net wrapping production equipment for rock wool composite panels, including a main frame, a lower conveying roller group is arranged from front to back at the lower part of the main frame, and a main frame above the lower conveying roller group is arranged on the main frame. The feeding part, the net wrapping part, the nail netti

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap