Fluted disc structure of crusher

A pulverizing tooth and pulverizer technology, applied in the application, feed, grain processing and other directions, can solve the problems of material waste and use cost, inconsistent looseness, affecting the pulverization quality, etc., and achieve the effect of simple structure, convenient production, convenient installation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0013] In order to further understand the content, features, and effects of the present invention, the following embodiments are given as examples, and detailed descriptions are as follows with accompanying drawings:

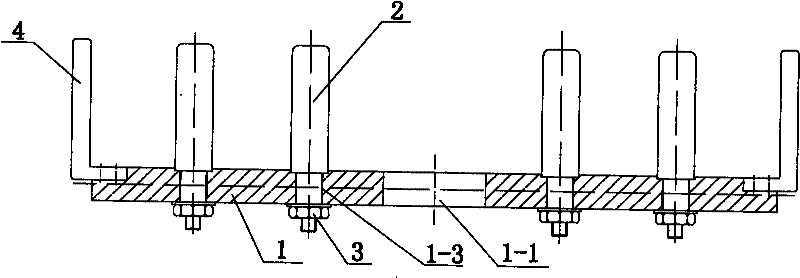

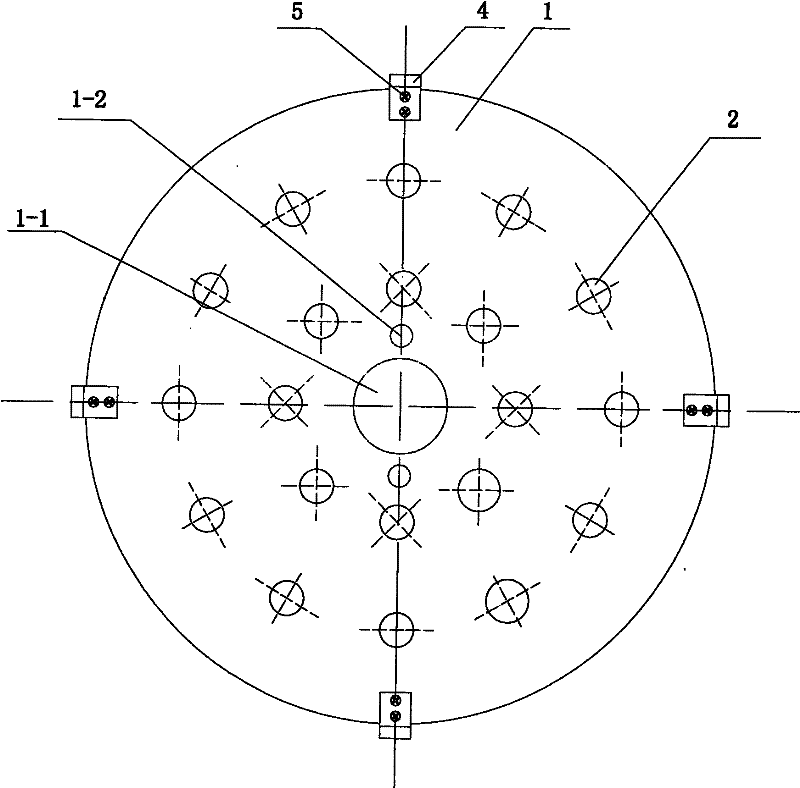

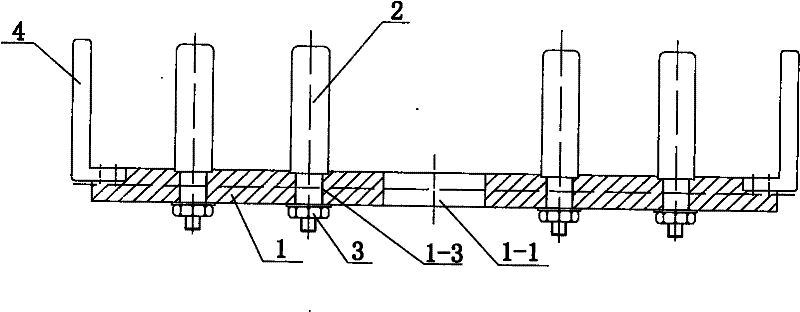

[0014] See figure 1 with figure 2 , A toothed disk structure for a pulverizer, comprising a circular disk body 1, a mounting hole 1-1 and a positioning hole 1-2 arranged in the center of the disk body 1, and a crushing tooth 2. The crushing tooth 2 is detachable Type installation structure, that is, installation holes 1-3 are evenly distributed on the end surface of the circular disc body 1, and the crushing teeth 2 are inserted into the installation holes 1-3, and the crushing teeth are fastened on the other end of the circular disc body 1. The nut 3 is fastened to the circular disk body 1, and crushing teeth 4 are evenly distributed on the outer circumference of the circular disk body 1, and the crushing teeth 4 are fastened to the circular disk body 1 by a fastene

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap