Hardcoat film, production method of hardcoat film, antireflection film, polarizing plate and display device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Example

[0047]The best mode for carrying out the present invention is described in detail below, but the present invention is not limited thereto.

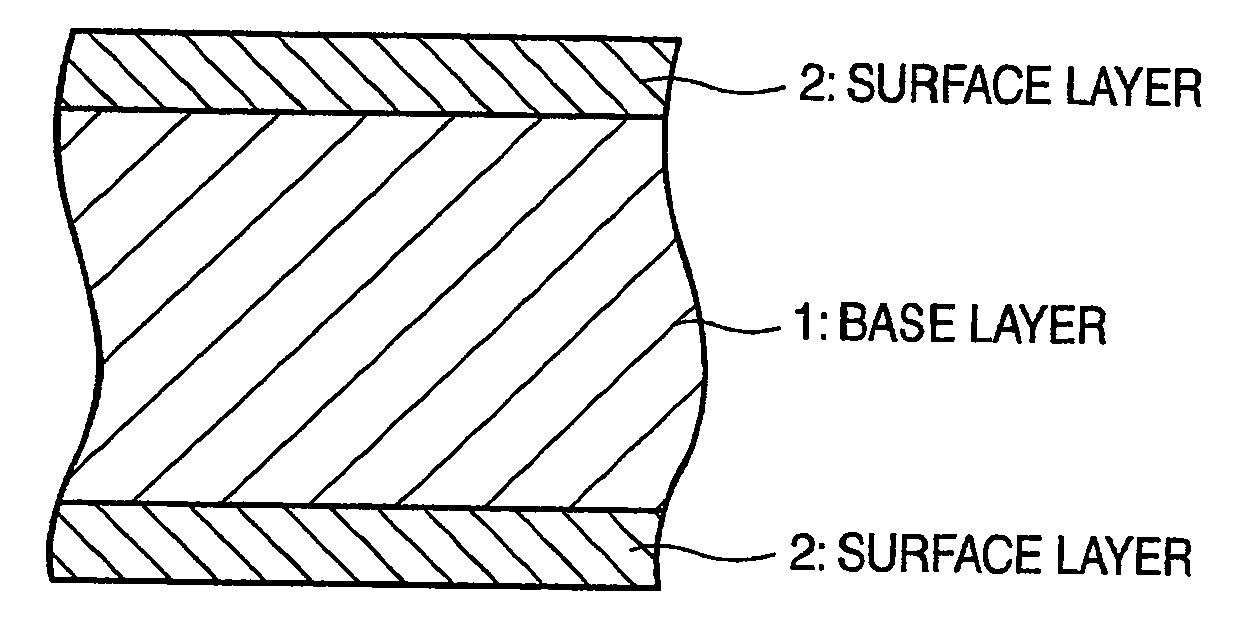

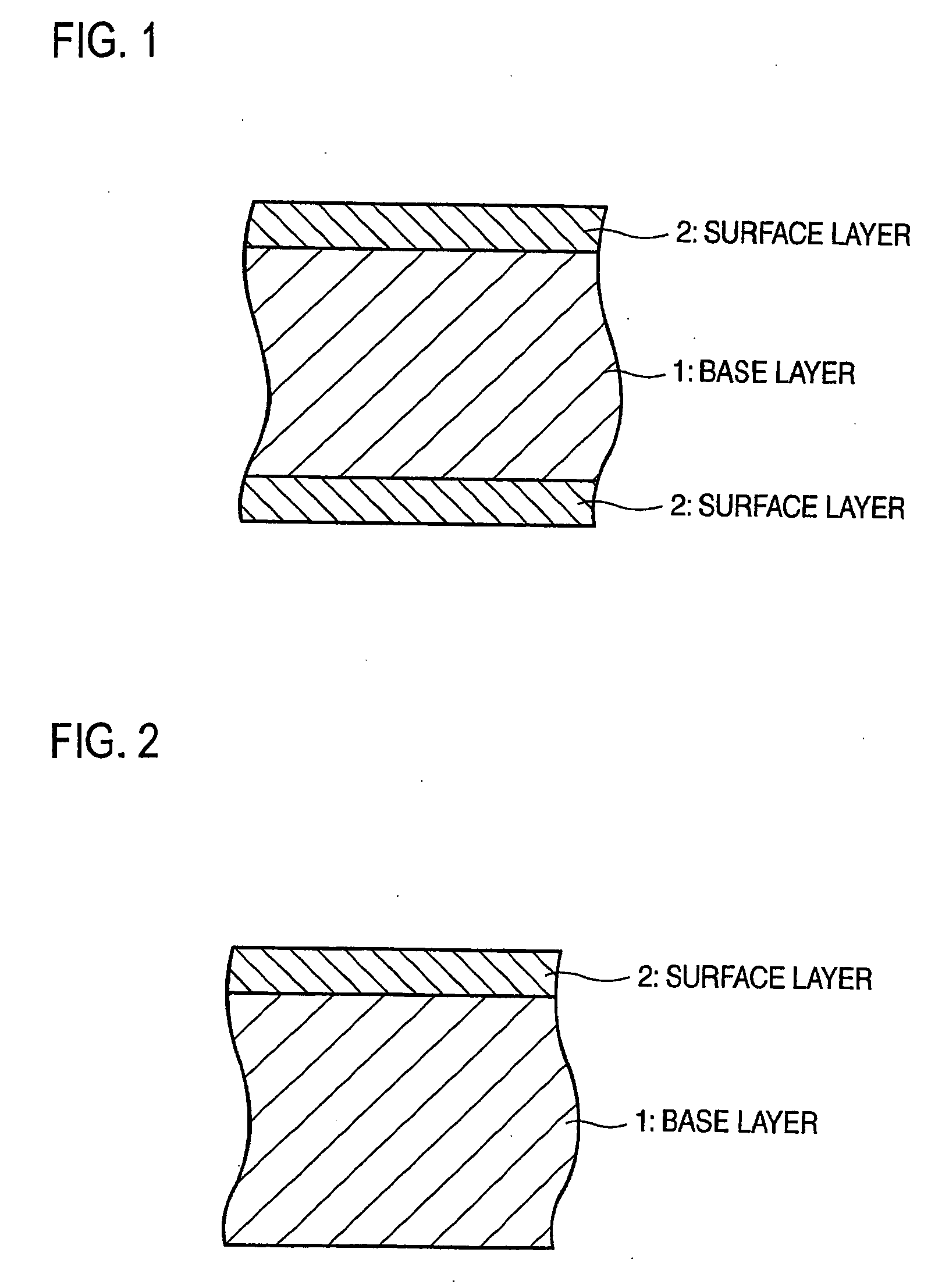

[0048]The hardcoat film of the present invention is a hardcoat film comprising a cellulose acylate film composed of at least a base layer and a surface layer and having a hardcoat layer on the surface layer side, wherein the surface layer contains an inorganic oxide fine particle and a cellulose acylate, the refractive index layer of the surface layer is from 1.49 to 1.56, the average film thickness of the surface layer is from 50 to 130 nm, and assuming that the refractive index of the hardcoat layer is nH, the refractive index of the surface layer is nS and the refractive index of the cellulose acylate film other than the surface layer is nC, the relationship of the following formula (I) is satisfied:

0.98nH×nC)1 / 2 / nS<1.02 Formula (I):

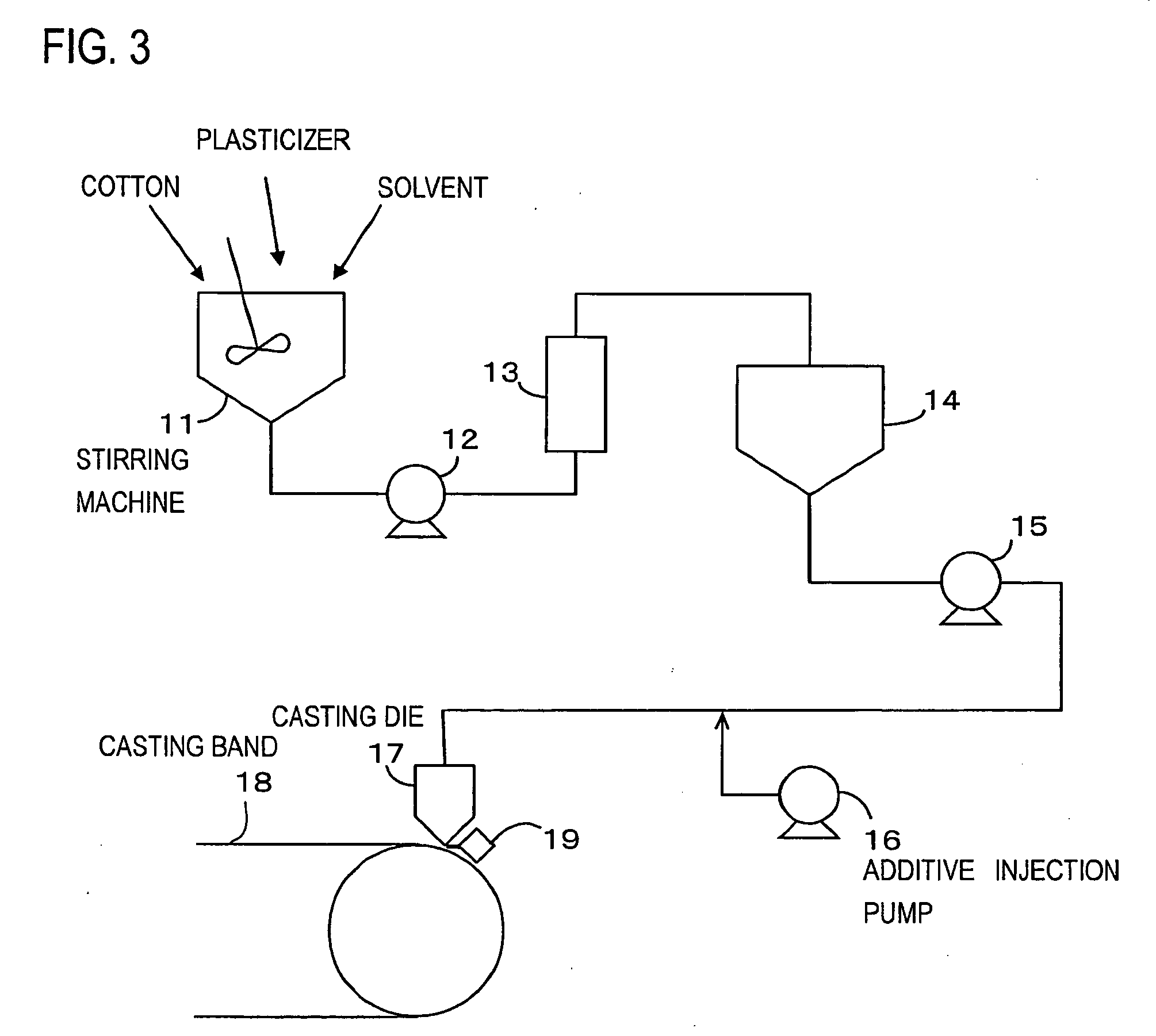

[0049]The production method of a hardcoat film of the present invention is a method for producing a hardcoat

PUM

| Property | Measurement | Unit |

|---|---|---|

| Nanoscale particle size | aaaaa | aaaaa |

| Particle diameter | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap