Wind turbine component having a lightweight structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Example

[0019]The detailed description explains embodiments of the invention, together with advantages and features, by way of example with reference to the drawings.

DETAILED DESCRIPTION OF THE INVENTION

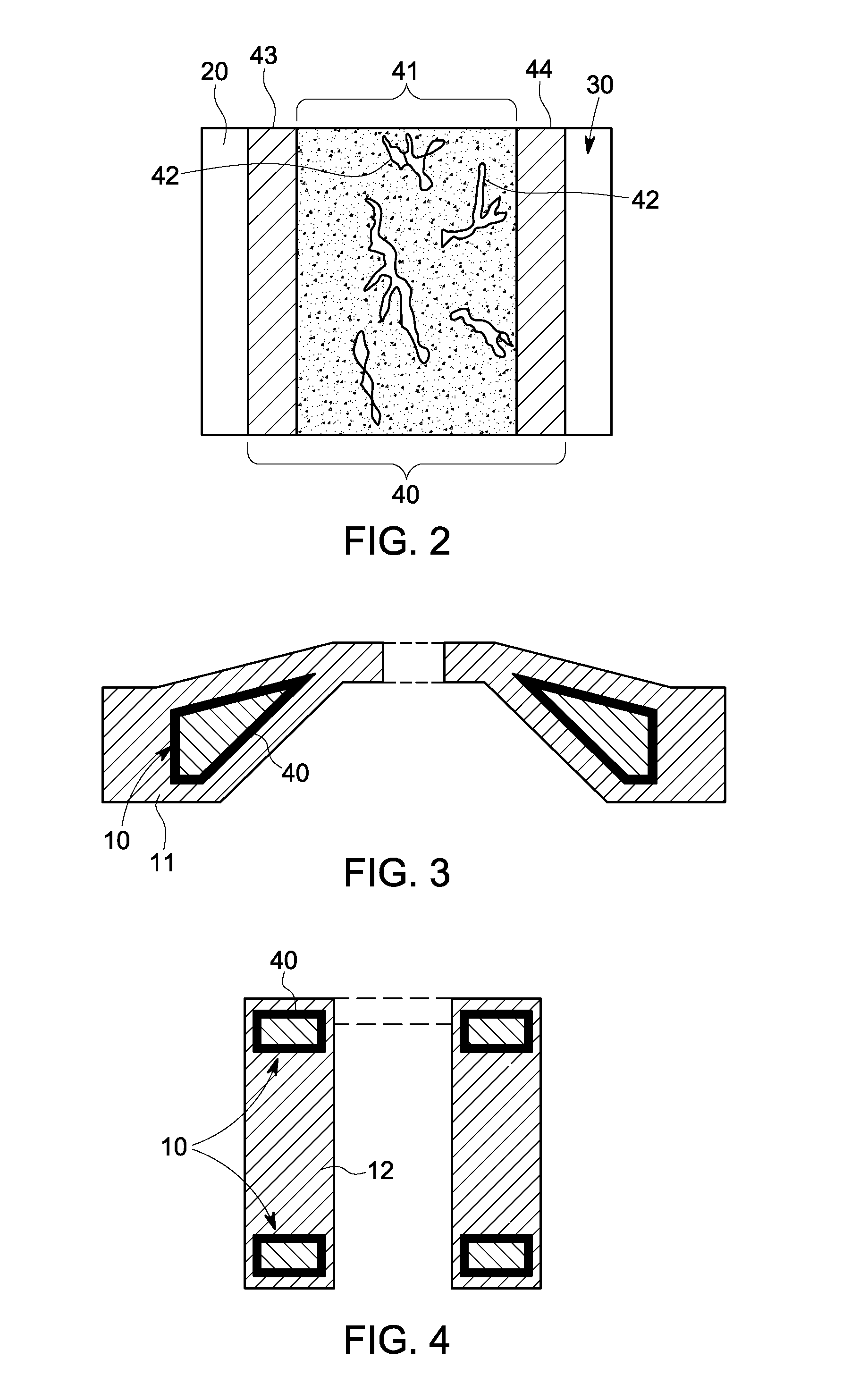

[0020]In accordance with aspects, a vibration damping noise reduction lightweight structure is provided for use as a multi-ton component of various types of apparatuses. These apparatuses may include, for example, wind turbines and similar components of power generation plants. The lightweight structure may include, for example, hollow tubing and / or castings of metallic materials filled by foams of metallic materials with a solidification metallurgical bond formed at an entire interface between the metallic materials and the foams.

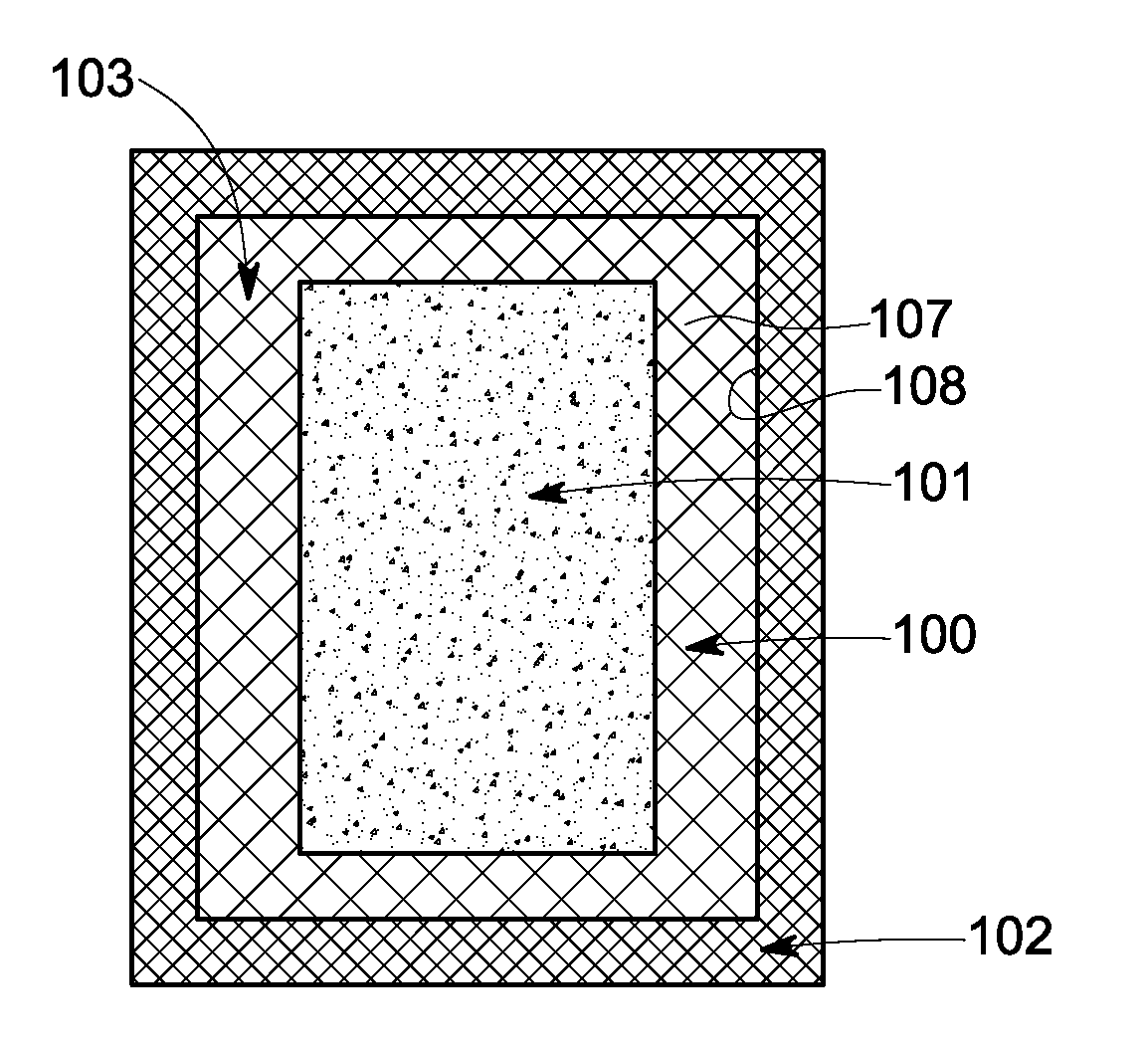

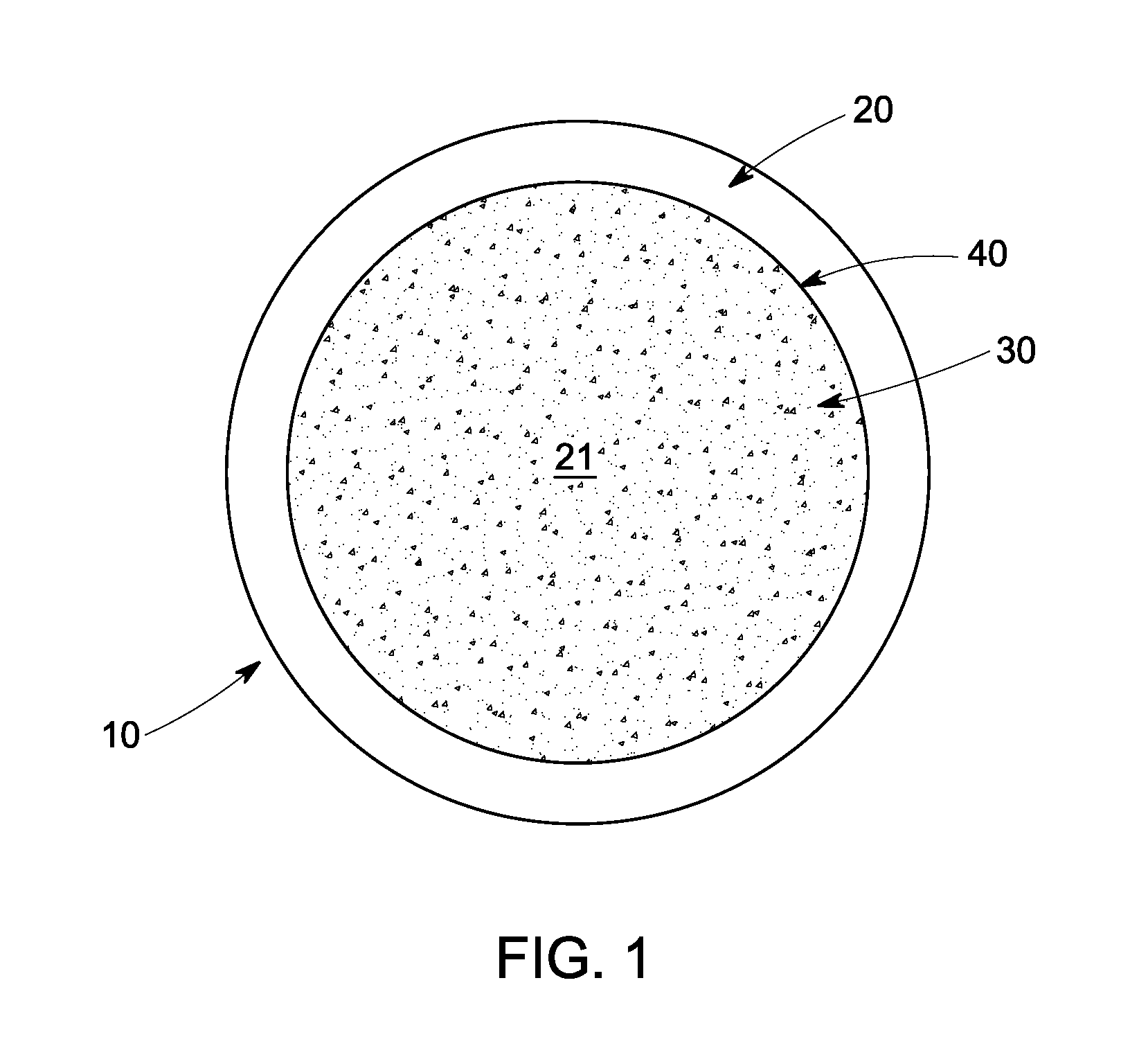

[0021]With reference now to FIG. 1, a wind turbine component configured to have a lightweight structure 10 to provide vibration damping and noise reduction is provided. The lightweight structure 10 includes a metallic matrix 20 formed to define a cavity 21, metallic

PUM

| Property | Measurement | Unit |

|---|---|---|

| Metallic bond | aaaaa | aaaaa |

| Distribution | aaaaa | aaaaa |

| Refractory | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap