Heat-expandable microspheres and application thereof

a technology of expansion performance and microspheres, which is applied in the field of heat expansion performance microspheres, can solve the problems of deterioration of expansion performance of heat expansion performance, insufficient heat resistance to meet the recent demand for high heat resistance microspheres, and heat expansion performance degradation. achieve good solvent resistance, high heat resistance, and high heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0137]An aqueous dispersion medium was prepared by adding 150 g of sodium chloride, 50 g of colloidal silica containing 20 wt % of silica, 4.0 g of polyvinyl pyrolidone and 1.0 g of ethylenediaminetetraaceticacid tetrasodiumsalt to 600 g of deionized water and adjusting the pH of the mixture within the range from 2.0 to 3.0.

[0138]An oily mixture was prepared by mixing 76 g of acrylonitrile, 40 g of methacrylonitrile, 180 g of methacrylic acid, 3 g of 2-hydroxyethylacrylate, 1 g of 1,9-nonanediol diacrylate, 30 g of isopentane, 30 g of isooctane and 8 g of the liquid containing 50% of di-sec-butyl peroxydicarbonate.

[0139]The aqueous dispersion medium and the oily mixture were mixed and agitated with a Homo-mixer to be prepared into a suspension. Then the suspension was transferred to a compressive reactor of 1.5-liter capacity, purged with nitrogen, and polymerized at 60° C. for 20 hours with agitation under the initial reaction pressure of 0.2 MPa. The resultant polymerization product

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Composition | aaaaa | aaaaa |

| Weight ratio | aaaaa | aaaaa |

Abstract

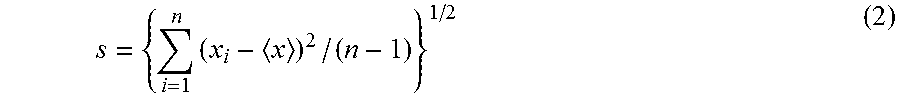

- Condition 1: The weight fraction of the monomers (A), (B) and (C) in the polymerizable component satisfy the inequality shown below.

- Condition 2: The ratio by weight of the monomer (B) to the monomer (C) ranges from 600:1 to 3:1.

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap