Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

4 results about "Amorphous metal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An amorphous metal (also known as metallic glass or glassy metal) is a solid metallic material, usually an alloy, with disordered atomic-scale structure. Most metals are crystalline in their solid state, which means they have a highly ordered arrangement of atoms. Amorphous metals are non-crystalline, and have a glass-like structure. But unlike common glasses, such as window glass, which are typically electrical insulators, amorphous metals have good electrical conductivity. There are several ways in which amorphous metals can be produced, including extremely rapid cooling, physical vapor deposition, solid-state reaction, ion irradiation, and mechanical alloying.Previously, small batches of amorphous metals had been produced through a variety of quick-cooling method, such as amorphous metal ribbons which had been produced by sputtering molten metal onto a spinning metal disk (melt spinning). The rapid cooling (on the order of millions of degrees Celsius a second) is too fast for crystals to form and the material is "locked" in a glassy state. Currently, a number of alloys with critical cooling rates low enough to allow formation of amorphous structure in thick layers (over 1 millimeter) have been produced; these are known as bulk metallic glasses (BMG). More recently, batches of amorphous steel with three times the strength of conventional steel alloys have been produced .

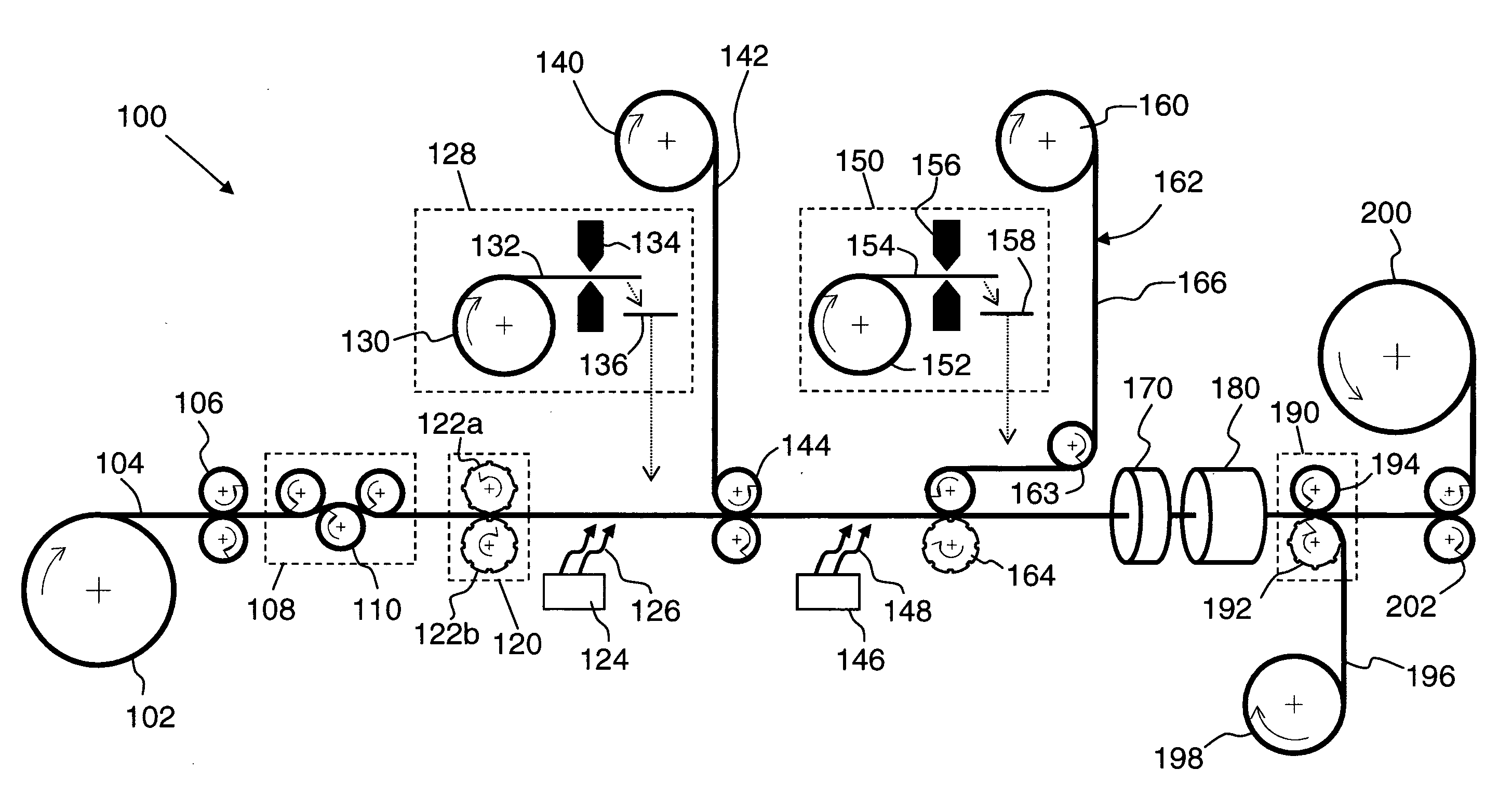

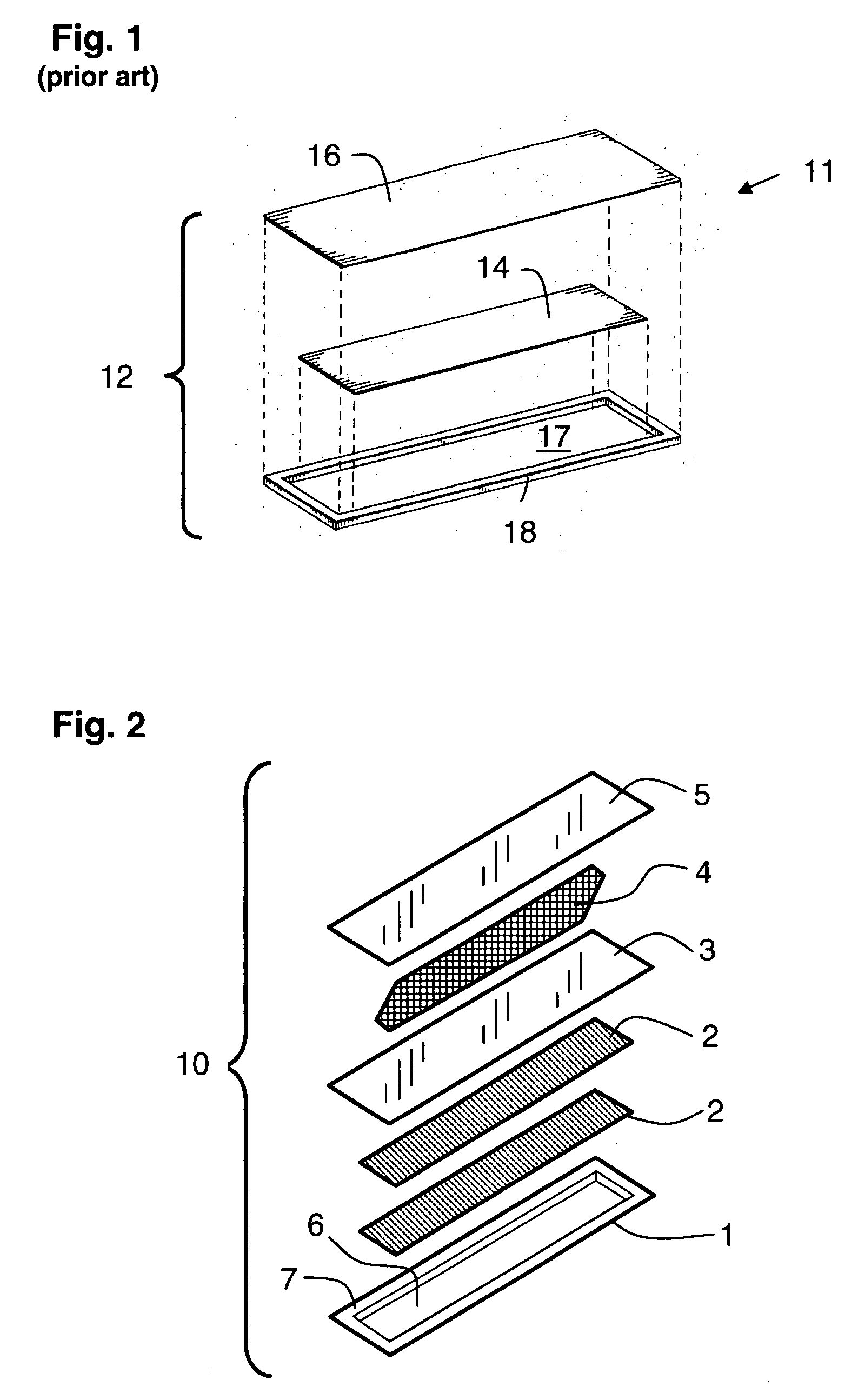

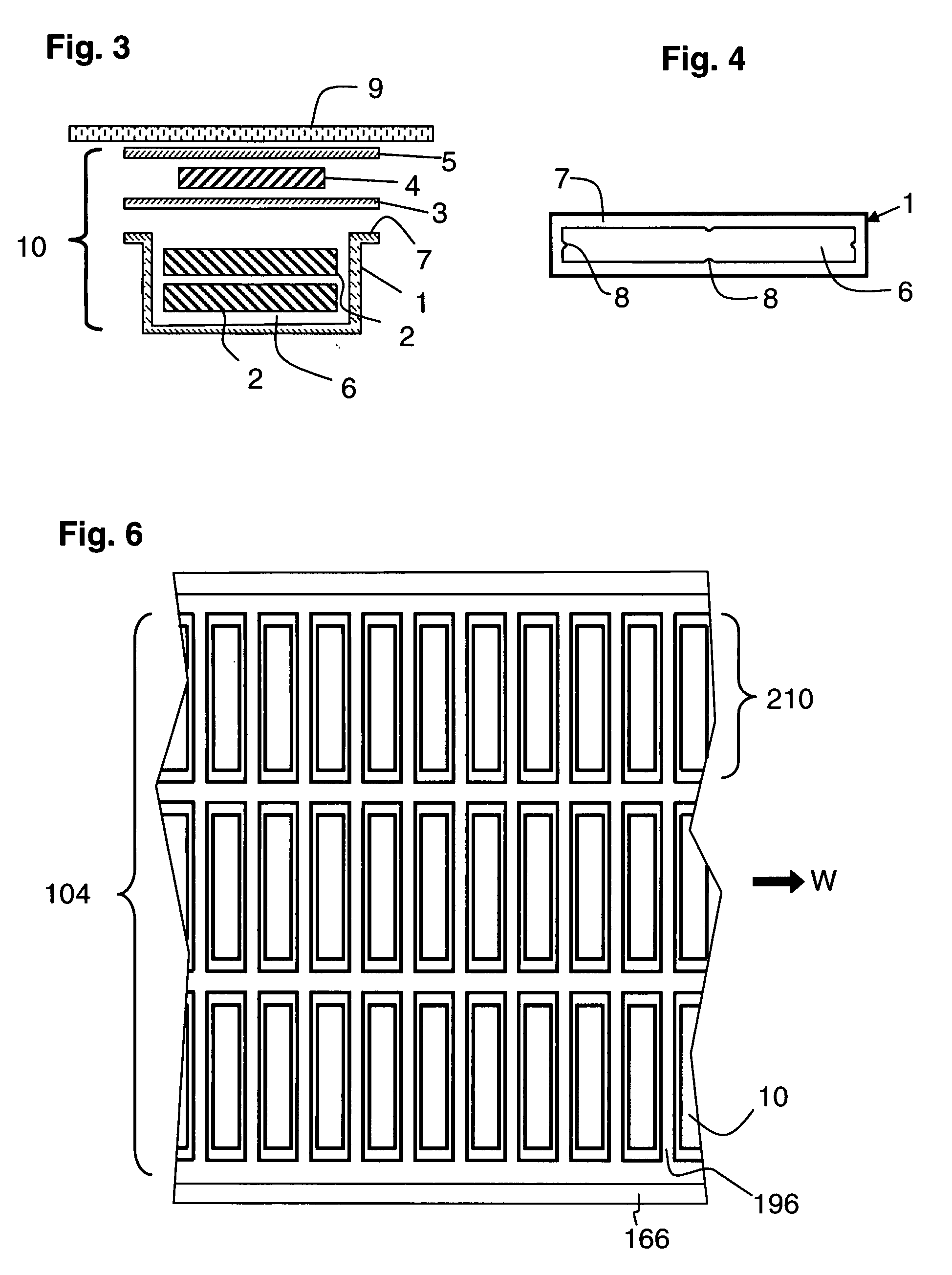

Electronic article surveillance marker

InactiveUS20070194927A1Improve production yieldImprove reliabilityElectronic circuit testingBurglar alarm by hand-portable articles removalMagnetic tension forceMonitoring system

Owner:PHENIX LABEL

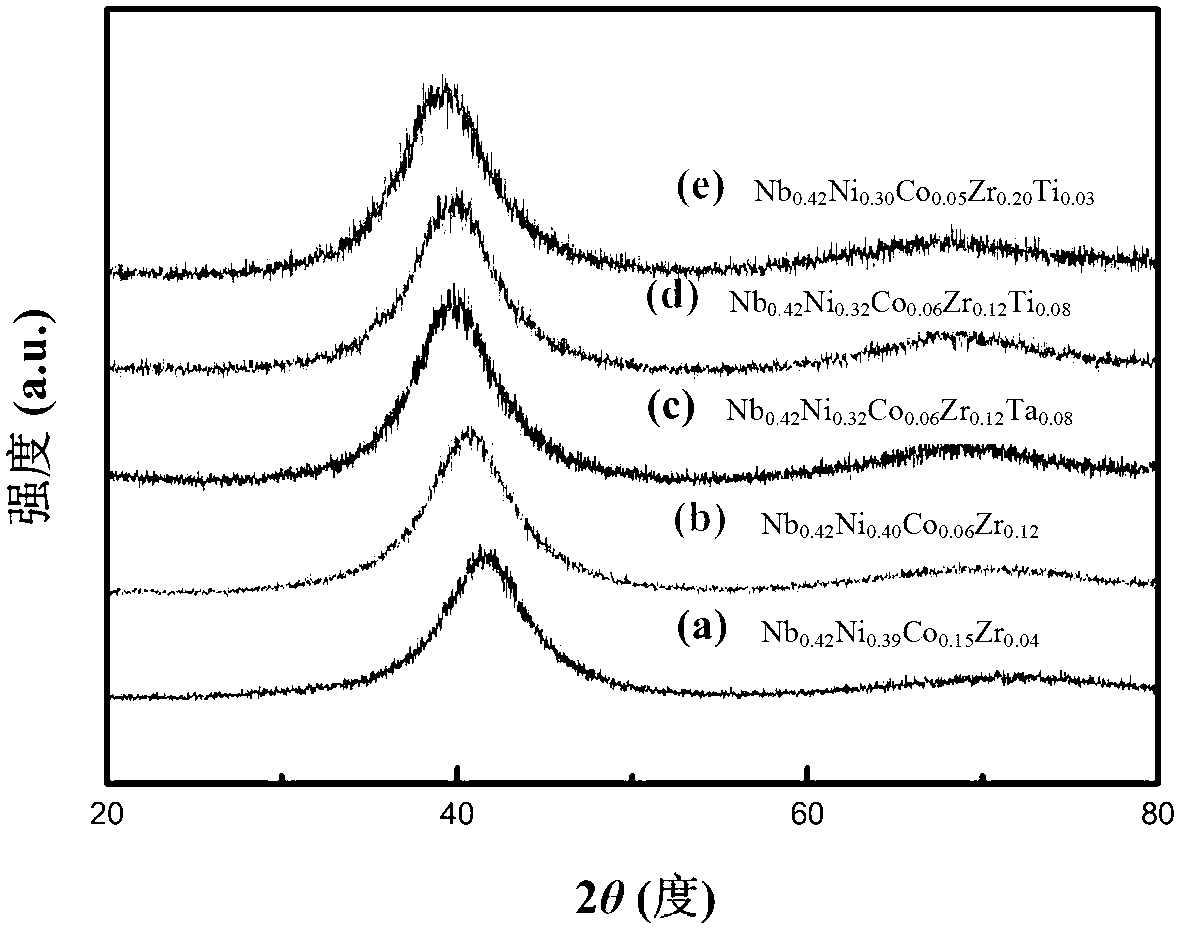

Preparation method of Nb-based amorphous alloy and stripe and hydrogen permeating metal film thereof

Owner:TSINGHUA UNIV

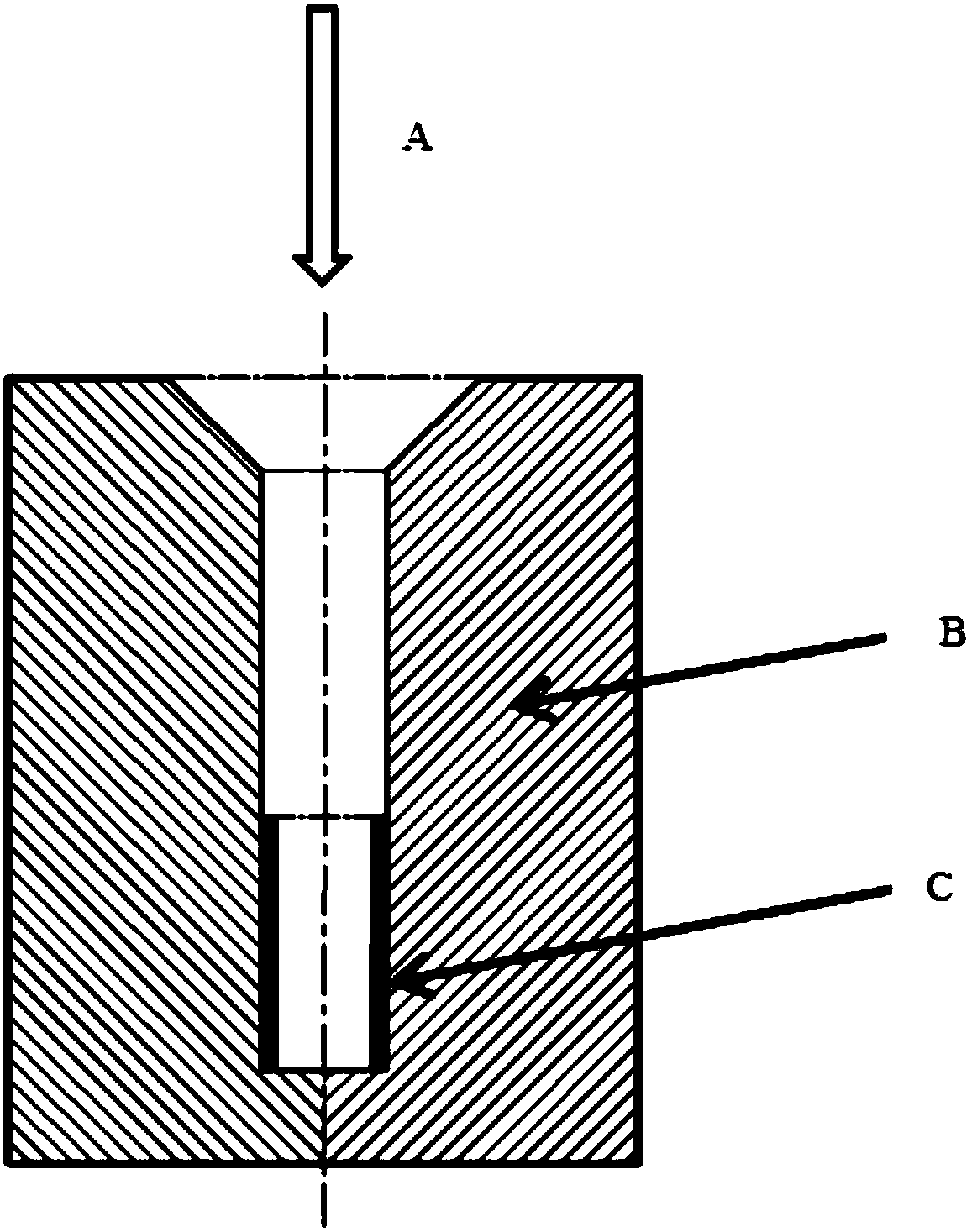

Method for improving indoor temperature compressing plasticity of amorphous alloy

ActiveCN108543930AImprove room temperature compression plasticityInhibit rapid expansionMaterials preparationAlloy composite

Owner:HARBIN INST OF TECH

Amorphous alloy with increased operating induction

A large magnetic amorphous metallic alloy core is annealed to minimize exciting power rather than core loss. The core has an exciting power less than 1 VA / kg when measured at 60 Hz and an operating induction of 1.40 to 1.45 Tesla, the measurement being carried out at ambient temperature. Such cores can be run at higher operating induction than those annealed to minimize core loss. The physical size of the transformer's magnetic components, including the core, is significantly reduced.

Owner:METGLAS INC

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap