Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

4 results about "Electric arc furnace" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An electric arc furnace (EAF) is a furnace that heats charged material by means of an electric arc. Industrial arc furnaces range in size from small units of approximately one ton capacity (used in foundries for producing cast iron products) up to about 400 ton units used for secondary steelmaking. Arc furnaces used in research laboratories and by dentists may have a capacity of only a few dozen grams. Industrial electric arc furnace temperatures can be up to 1,800 °C (3,272 °F), while laboratory units can exceed 3,000 °C (5,432 °F).

Electric furnace smoke removal and dust collection device

InactiveCN104390478AIncreasing energy efficiencyControl devices for furnacesElectric arc furnaceSmoke hood

The invention discloses an electric furnace smoke removal and dust collection device which comprises a roof smoke hood, a bag type dust collector, a spiral conveyor, a smoke ventilator, a water cooling bent pipe, a movable sleeve, a water cooling pipeline and a settling chamber. The roof smoke hood is connected with the bag type dust collector through a pipeline, the bag type dust collector is connected with the smoke ventilator, an ash discharge port of the bag type dust collector is positioned above the spiral conveyor, an output end of the water cooling bent pipe is connected with one end of the movable sleeve, the other end of the movable sleeve is connected with one end of the water cooling pipeline, the other end of the water cooling pipeline is connected with an input end of the settling chamber, and an output end of the settling chamber is connected with the bag type dust collector. Smoke dust generated by an electric furnace can be effectively and rapidly removed by the aid of a straight-line smoke removal structure based on an existing roof smoke hood.

Owner:CHANGZHOU FEIYU CHEM

Method for melting purification of magnesia by using waste magnesium product

InactiveCN101837996ADoes not affect normal useQuality is not affectedChemical industryMagnesiaCompression moldingTunnel kiln

Owner:DASHIQIAO WEIMING FURNACE MATERIAL

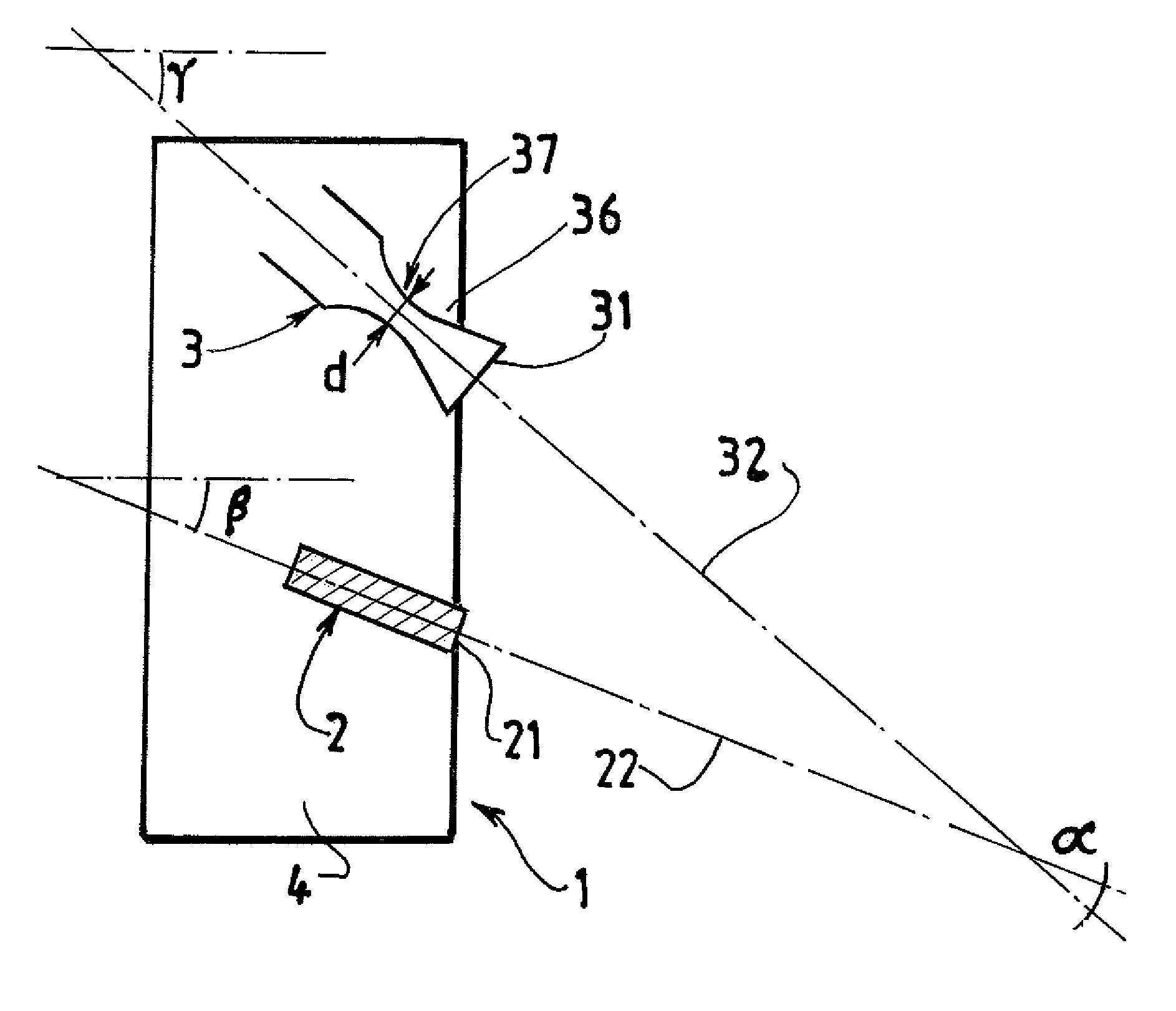

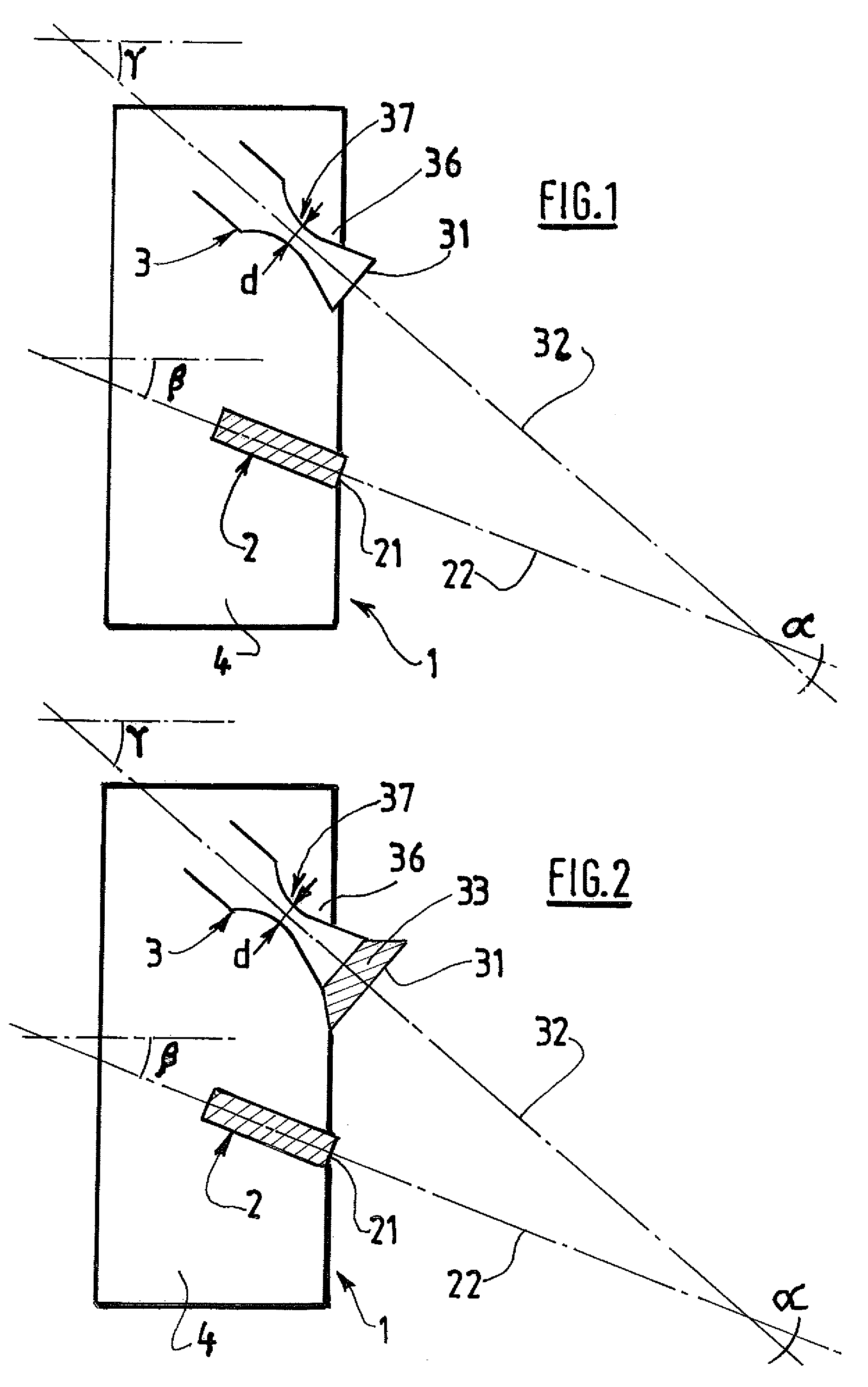

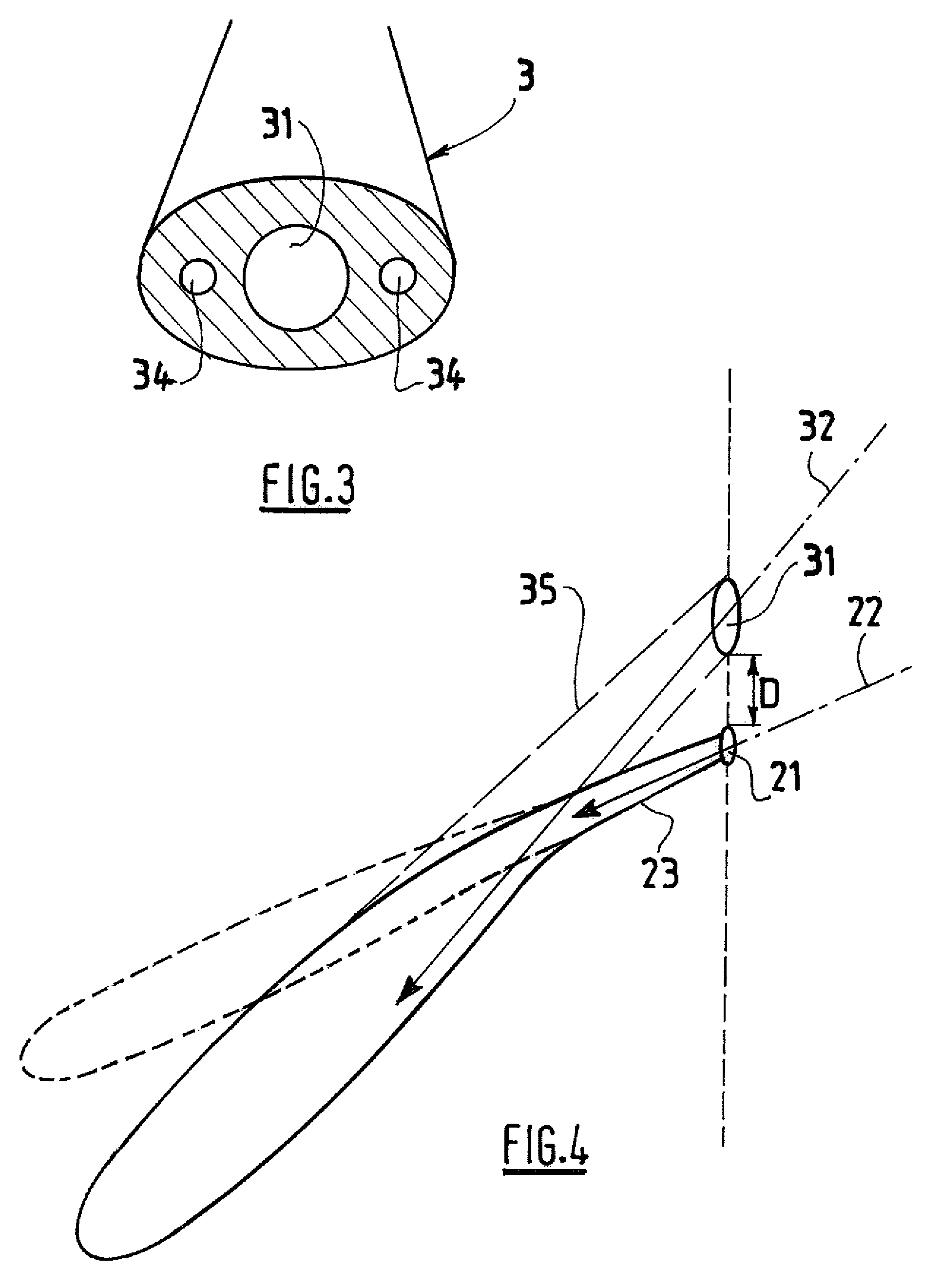

Combined burner and lance apparatus for electric arc furnaces

InactiveUS8333819B2Improve energy efficiencyEliminate cold spotFurnace componentsManufacturing convertersCombustorElectric arc furnace

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE

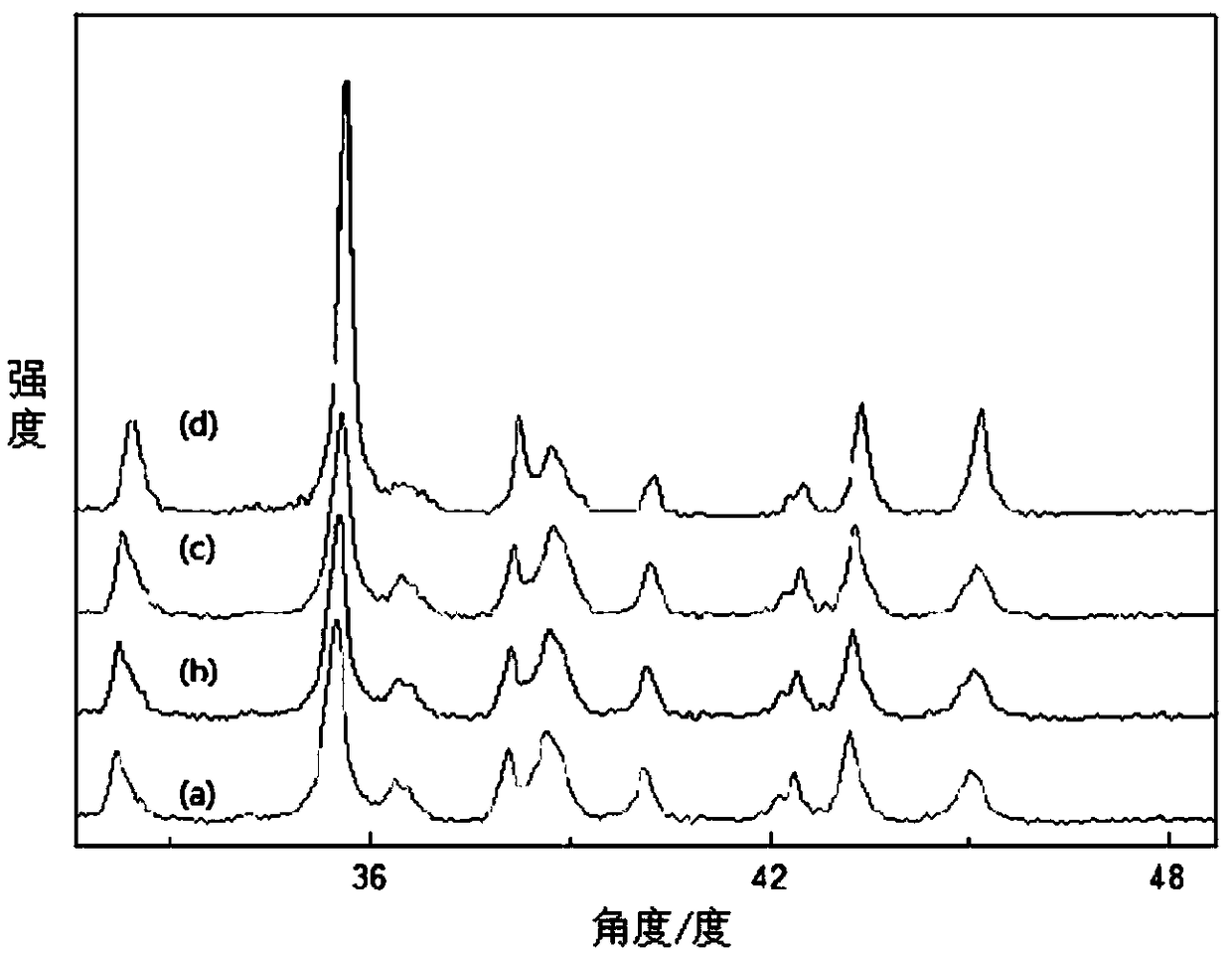

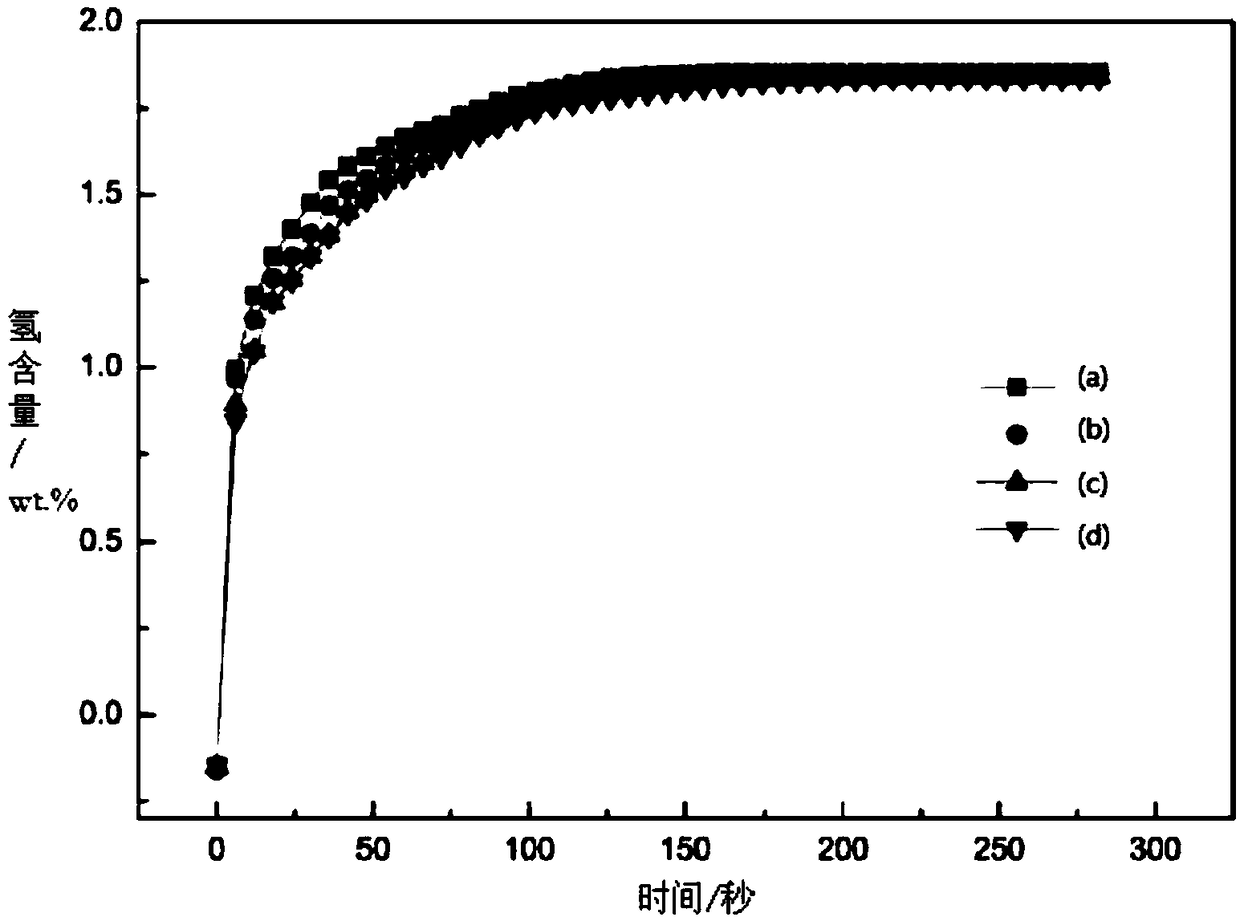

Zr-Fe alloy for tritium storage and preparation method thereof

InactiveCN108149070ALow costFast rate of hydrogen absorption and desorption (tritium)Electric arc furnaceDesorption

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap