Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

4 results about "Laser drilling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Laser drilling is the process of creating thru-holes, referred to as “popped” holes or “percussion drilled” holes, by repeatedly pulsing focused laser energy on a material. The diameter of these holes can be as small as 0.002” (~50 μm). If larger holes are required, the laser is moved around the circumference of the “popped” hole until the desired diameter is created; this technique is called “trepanning”.

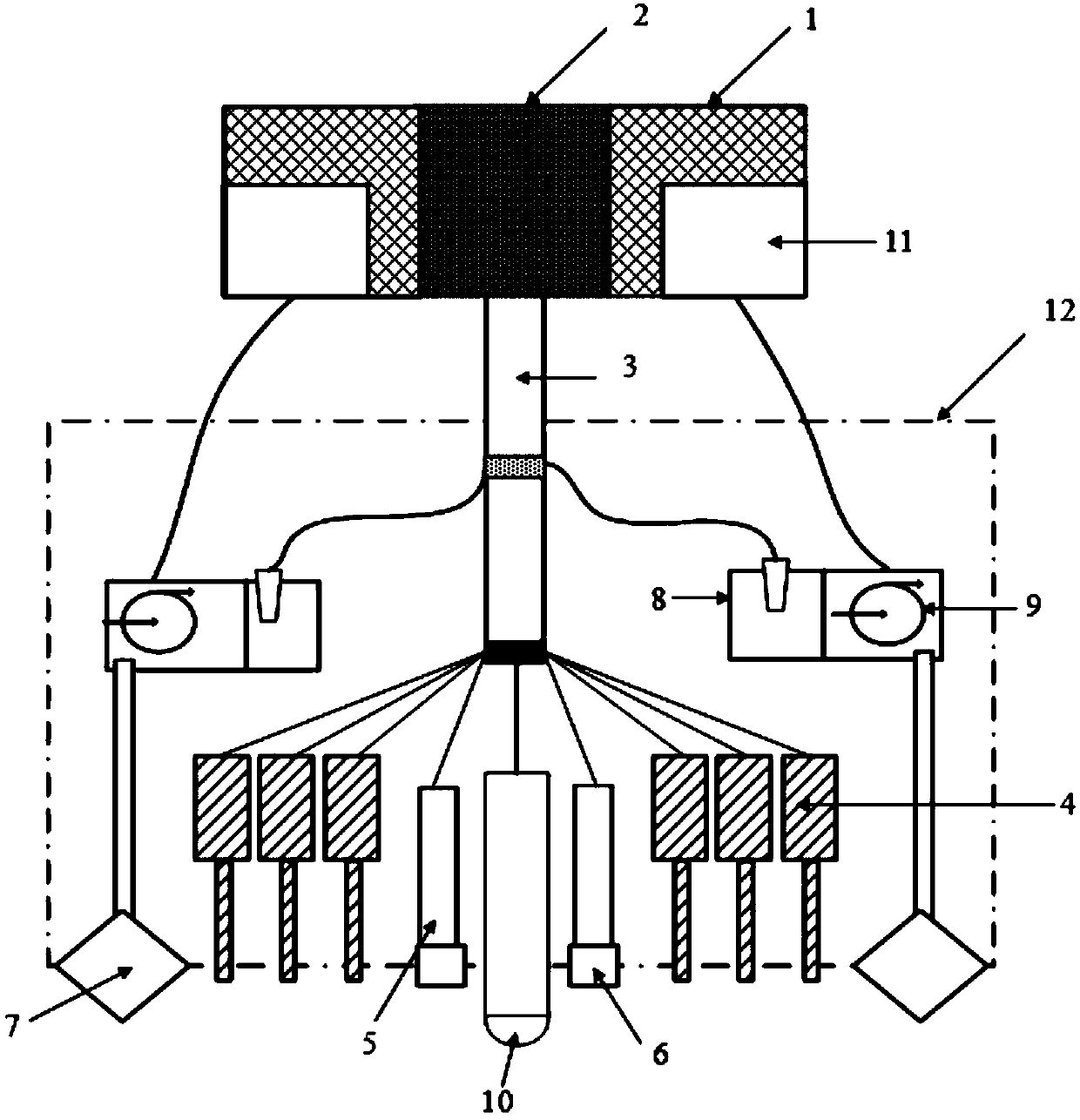

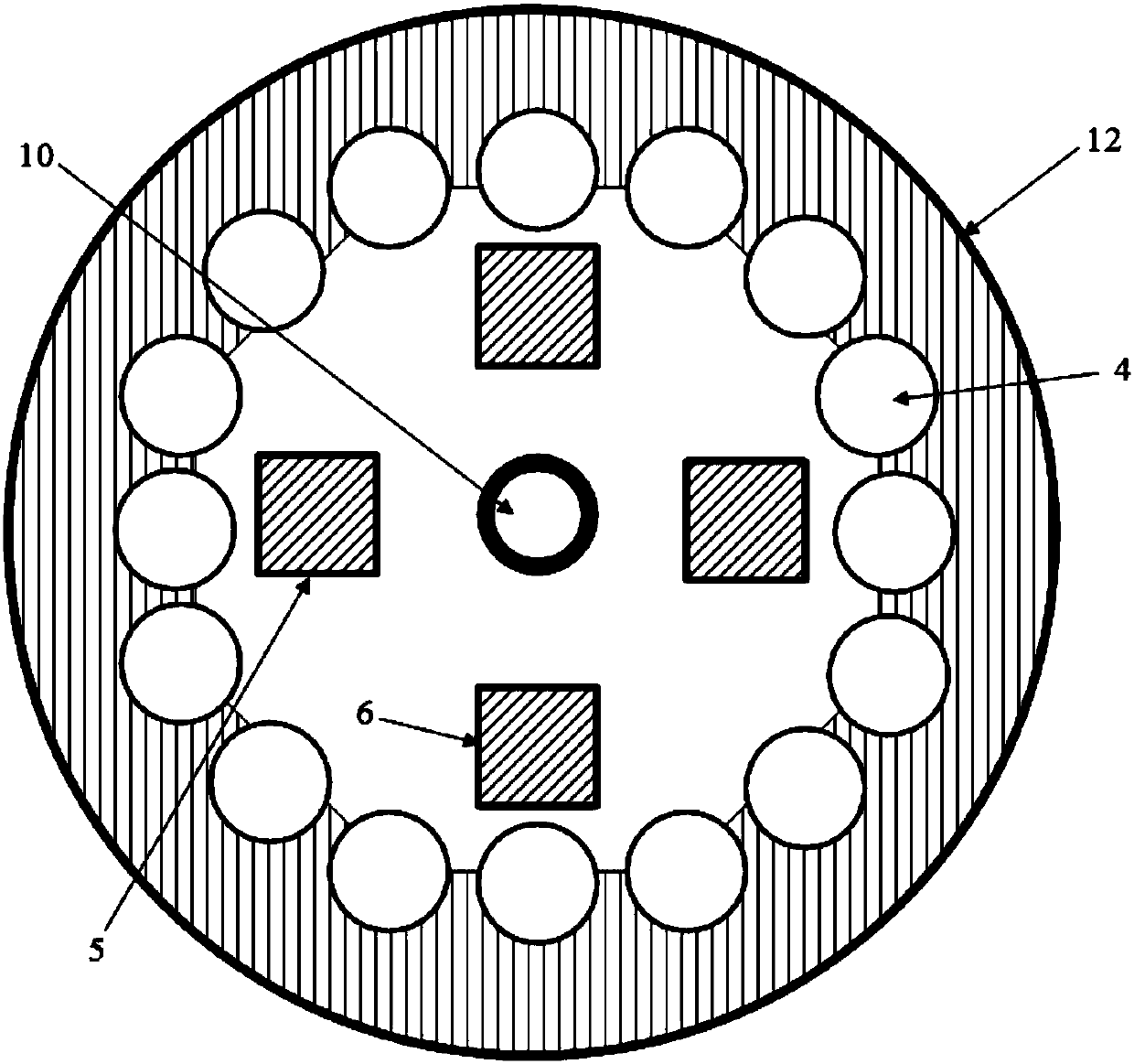

Ultrasonic laser drilling device

ActiveCN107620566ARock breaking drillingGood effectDrilling machines and methodsLaser arrayWater circulation

Owner:CHINA WEAPON EQUIP RES INST

Method for improving quality of inner wall of laser processing micropore based on dual cavitation effect

ActiveCN114589405AImprove inner wall qualityDecrease produces trendProcess efficiency improvementLaser beam welding apparatusUltrasonic cavitationLaser processing

Owner:SHANDONG UNIV OF TECH

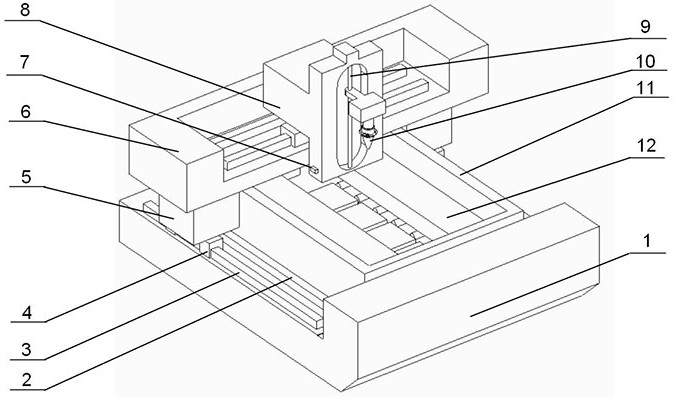

Laser drilling machine

InactiveCN112008261APrevent splashAvoid discomfortLaser beam welding apparatusRubber ringControl system

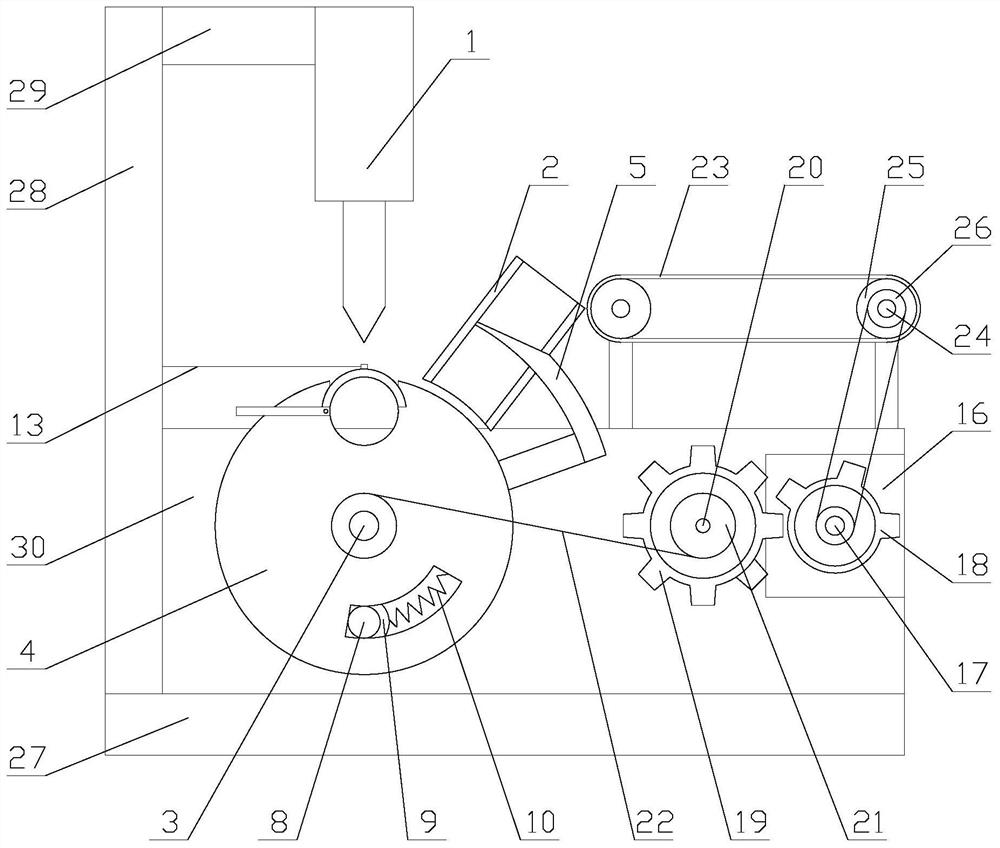

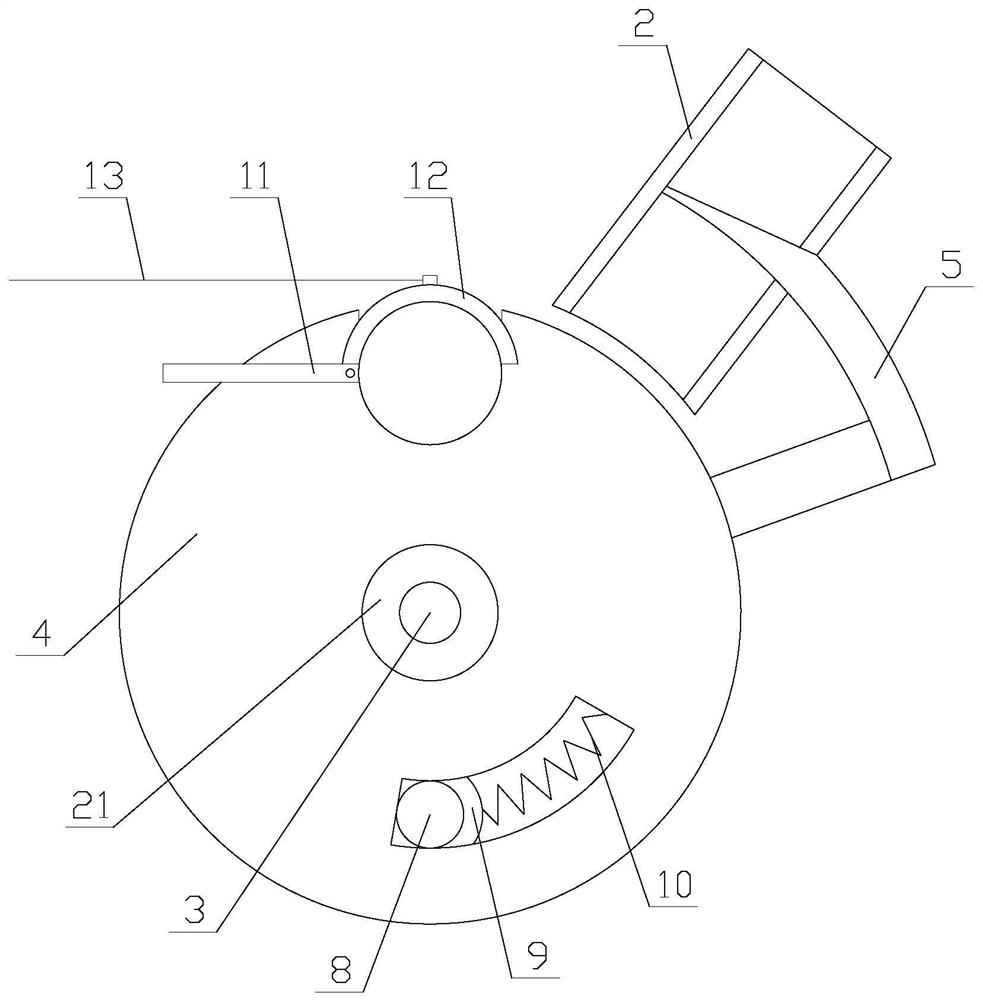

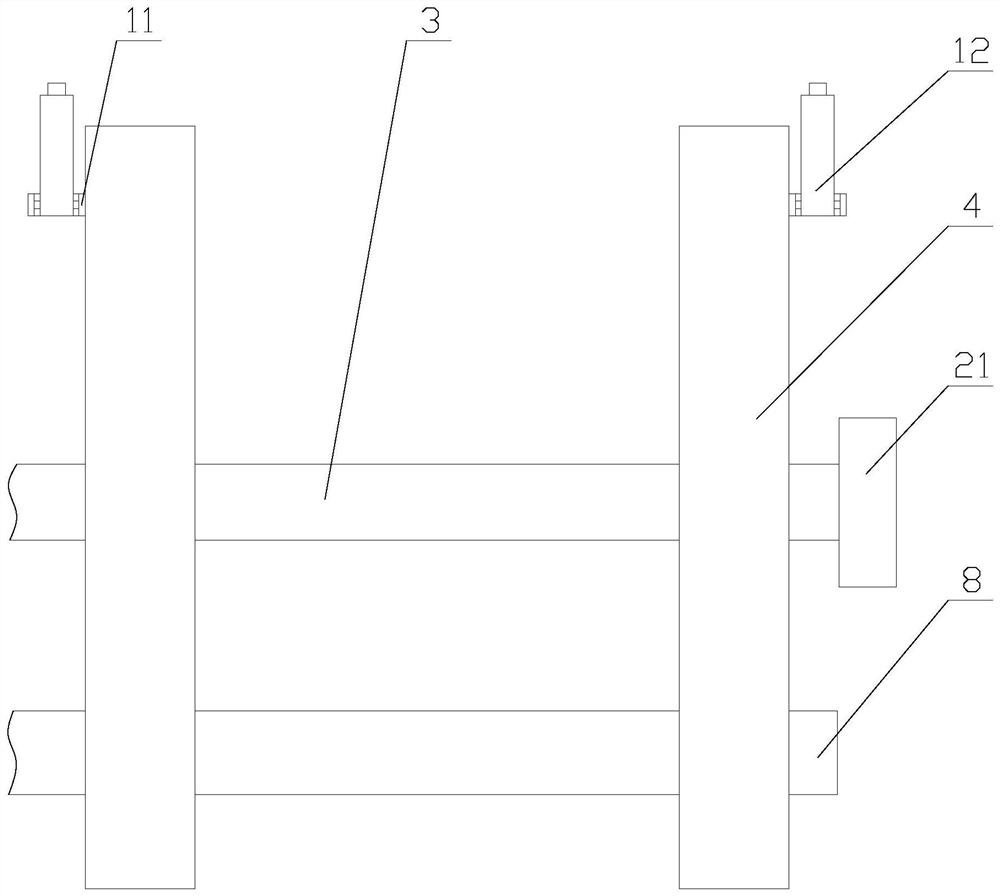

The invention discloses a laser drilling machine. The laser drilling machine comprises a laser device, a laser collimation and beam expansion optical system, a focusing optical system, a machining platform and a laser drilling machine control system. The laser drilling machine control system controls the relative positions of the focused laser beams and the machining platform, a protective cover is installed outside the laser (1), the machining platform is located at the bottom of the laser, the bottom of the protective cover makes contact with the upper end face of the machining platform, andthe lower end of the protective cover surrounds the protective cover by a circle and protrudes outwards to form an installation part. The laser drilling machine is simple in structure, the outer partof the laser can be effectively covered by the protective cover and a rubber ring; scrap iron is prevented from splashing to the outside, the laser is cooled through wind energy generated by a cooling fan, the generated scrap iron is blown to laser light through the wind energy, the scrap iron is vaporized again by the laser light, the amount of the scrap iron is greatly reduced, meanwhile, lightcan be effectively blocked through the protective cover, so that discomfort of eyes is avoided.

Owner:SHENZHEN HAOCHUANGSHENG TECH CO LTD

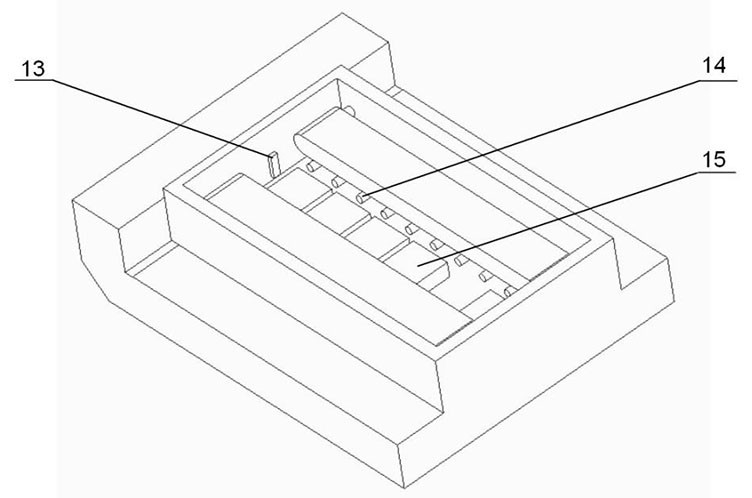

Automatic laser drilling device for plastic pipe

InactiveCN113601038AAchieve protectionReduce usageLaser beam welding apparatusEngineeringMechanical engineering

Owner:广州星龙商业管理有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap