Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

5 results about "Liquefaction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In materials science, liquefaction is a process that generates a liquid from a solid or a gas or that generates a non-liquid phase which behaves in accordance with fluid dynamics. It occurs both naturally and artificially. As an example of the latter, a "major commercial application of liquefaction is the liquefaction of air to allow separation of the constituents, such as oxygen, nitrogen, and the noble gases." Another is the conversion of solid coal into a liquid form usable as a substitute for liquid fuels.

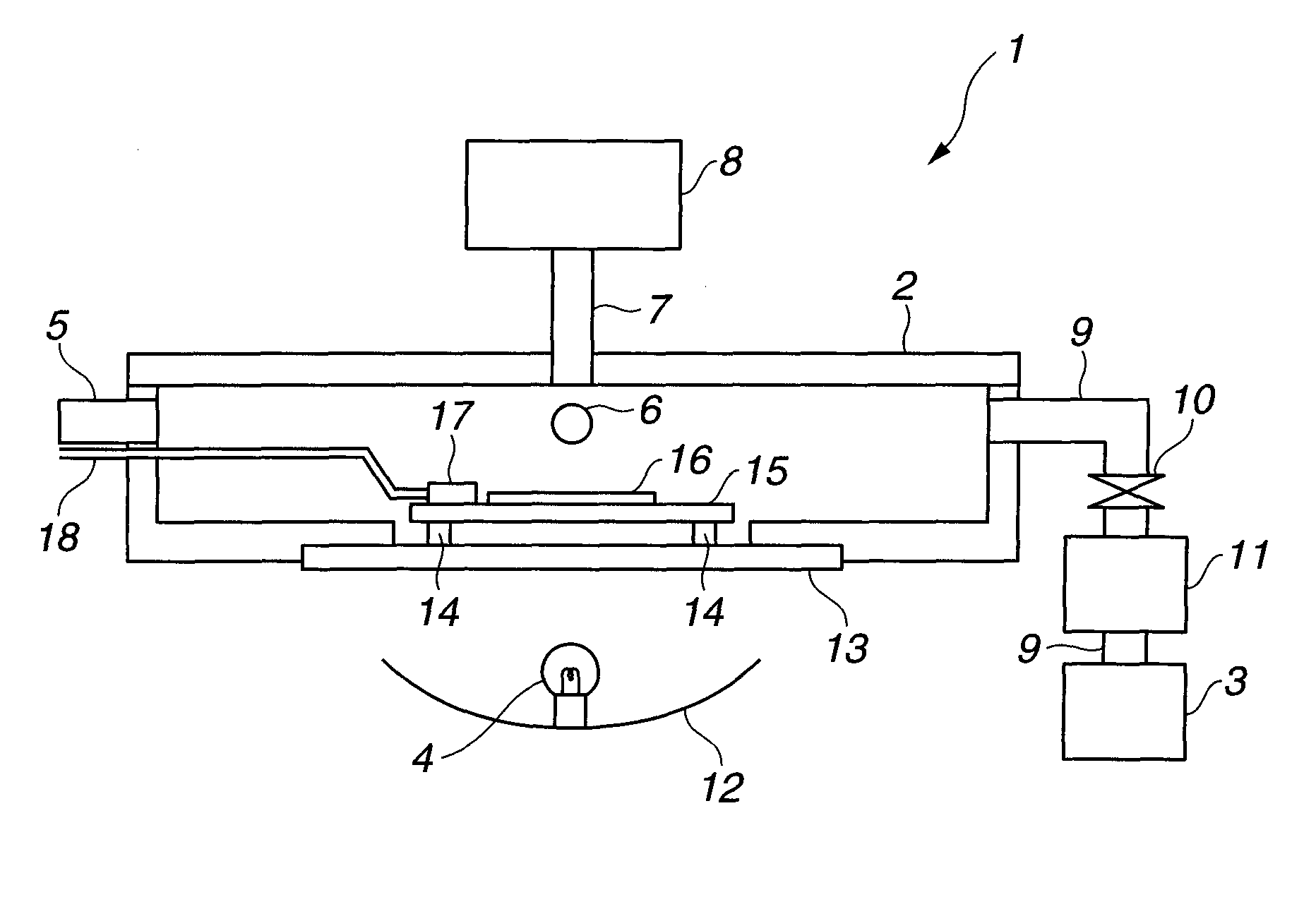

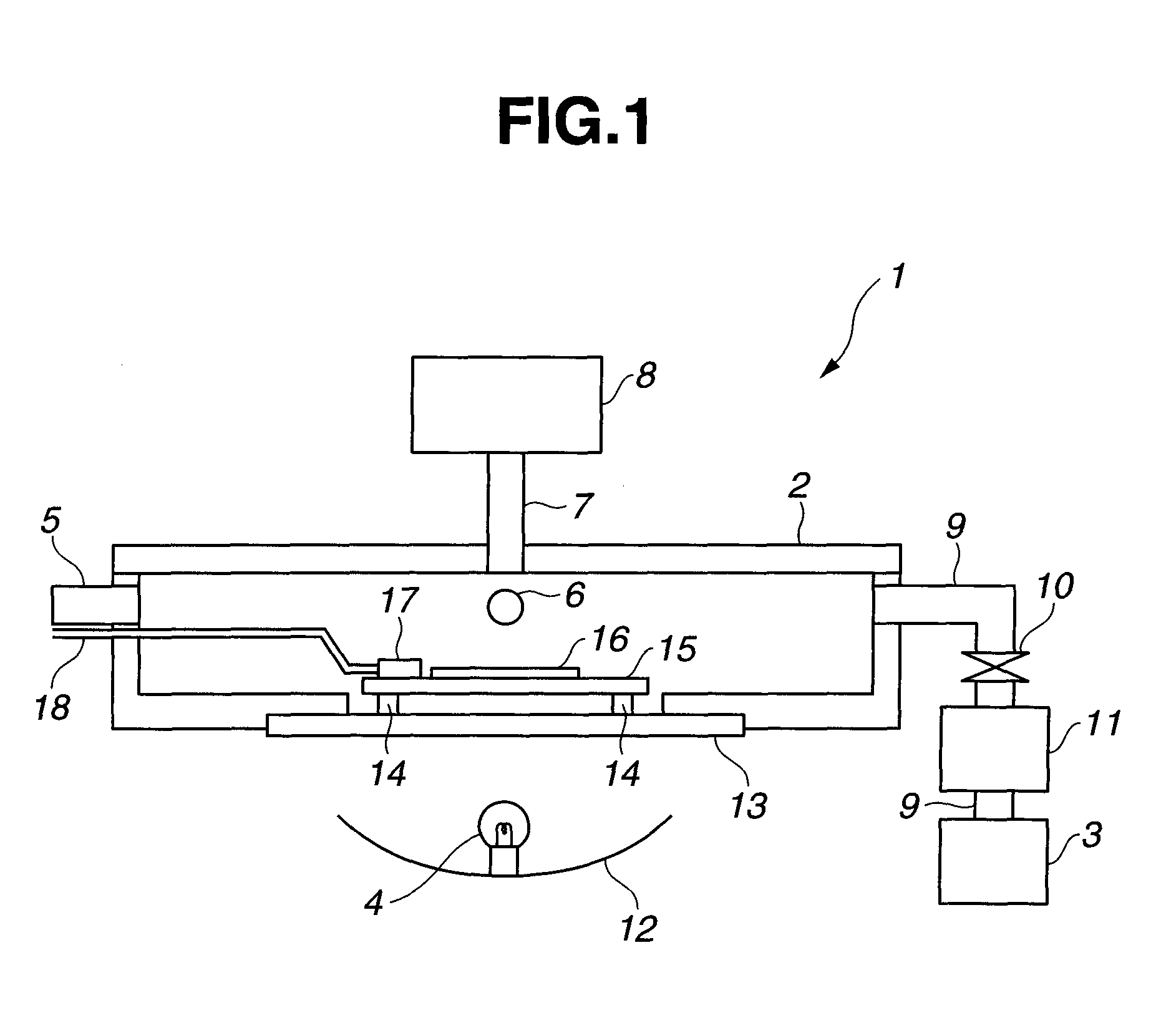

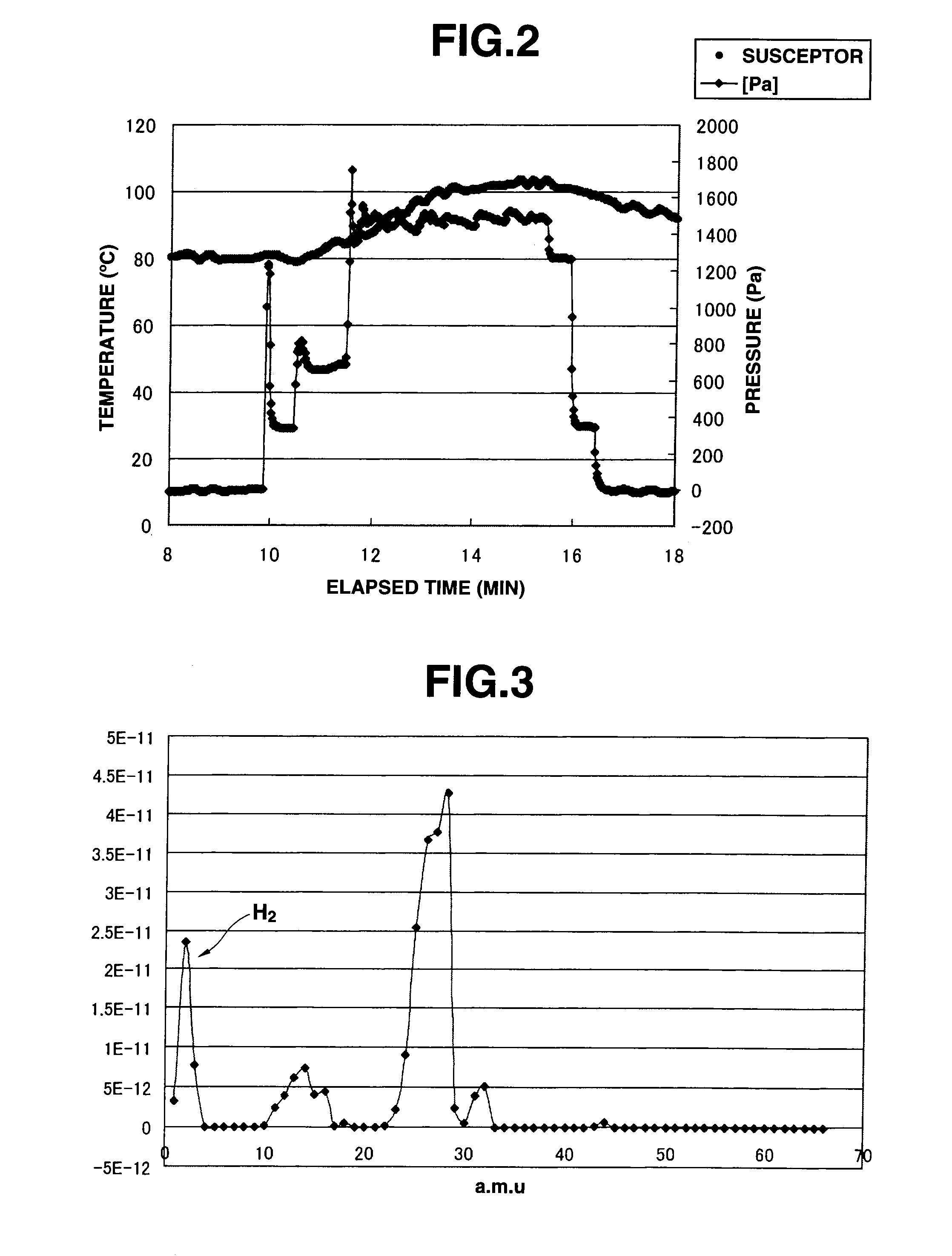

Method of removing resist and apparatus therefor

ActiveUS20100139708A1Easy to moveLow vapor pressureDecorative surface effectsHollow article cleaningResistSusceptor

Owner:MEIDENSHA ELECTRIC MFG CO LTD

Cooling circulating system, natural gas liquefaction device, operation method and improvement method of cooling circulating system

The invention provides a cooling circulating system (61). The cooling circulating system (61) is equipped with a refrigerant compressor (1) for compressing a refrigerant, a condenser (10) for cooling and condensing the refrigerant which is compressed by the refrigerant compressor (1), a reservoir (11) for accommodating the refrigerant which is condensed by the condenser (10), dilation mechanism (18) for dilating the refrigerant from the reservoir (11), an evaporation mechanism (19) for cooling an object to be cooled by heat exchange with the refrigerant which is dilated by the dilation mechanism (18) and vaporizing the refrigerant which is provided by the refrigerant compressor (1), and an auxiliary cooling mechanism (62) which is equipped with a line (47) for an auxiliary refrigerant to flow in and run through the reservoir (11) and cools the refrigerant in the reservoir (11) by the heat exchange with the refrigerant which flow in the line (47) before the refrigerant compressor (1) is started. Therefore, the power for starting the refrigerant compressor can be reduced, and the refrigerant compressor can be stably started by a drive source with a small torque.

Owner:HITACHI LTD

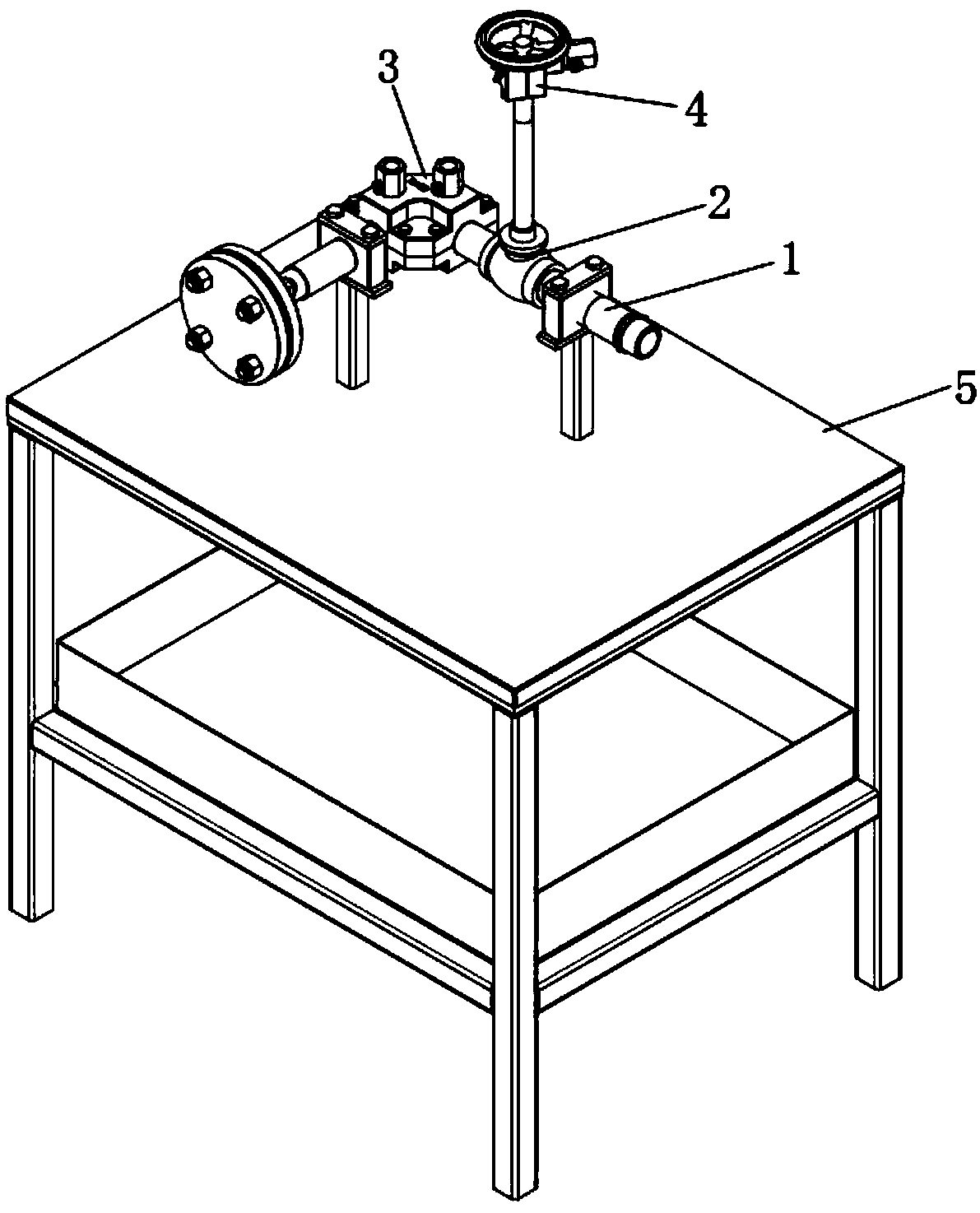

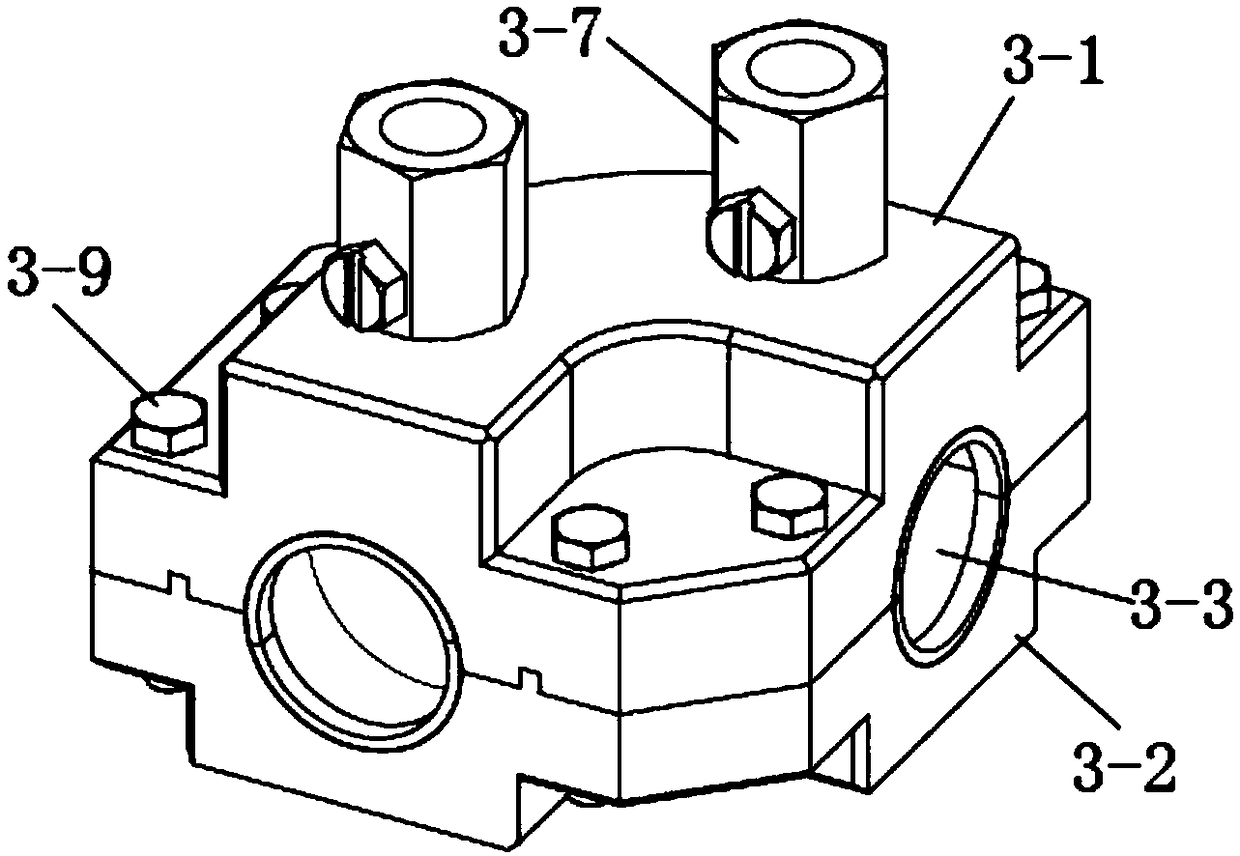

Low temperature liquefaction vehicle fuel tanker operation box pipeline equipment plugging simulation test bench

PendingCN109459225AMachine part testingFluid-tightness measurement using fluid/vacuumGas cylinderEngineering

Owner:SHANGHAI INST OF SPECIAL EQUIP INSPECTION & TECHN RES

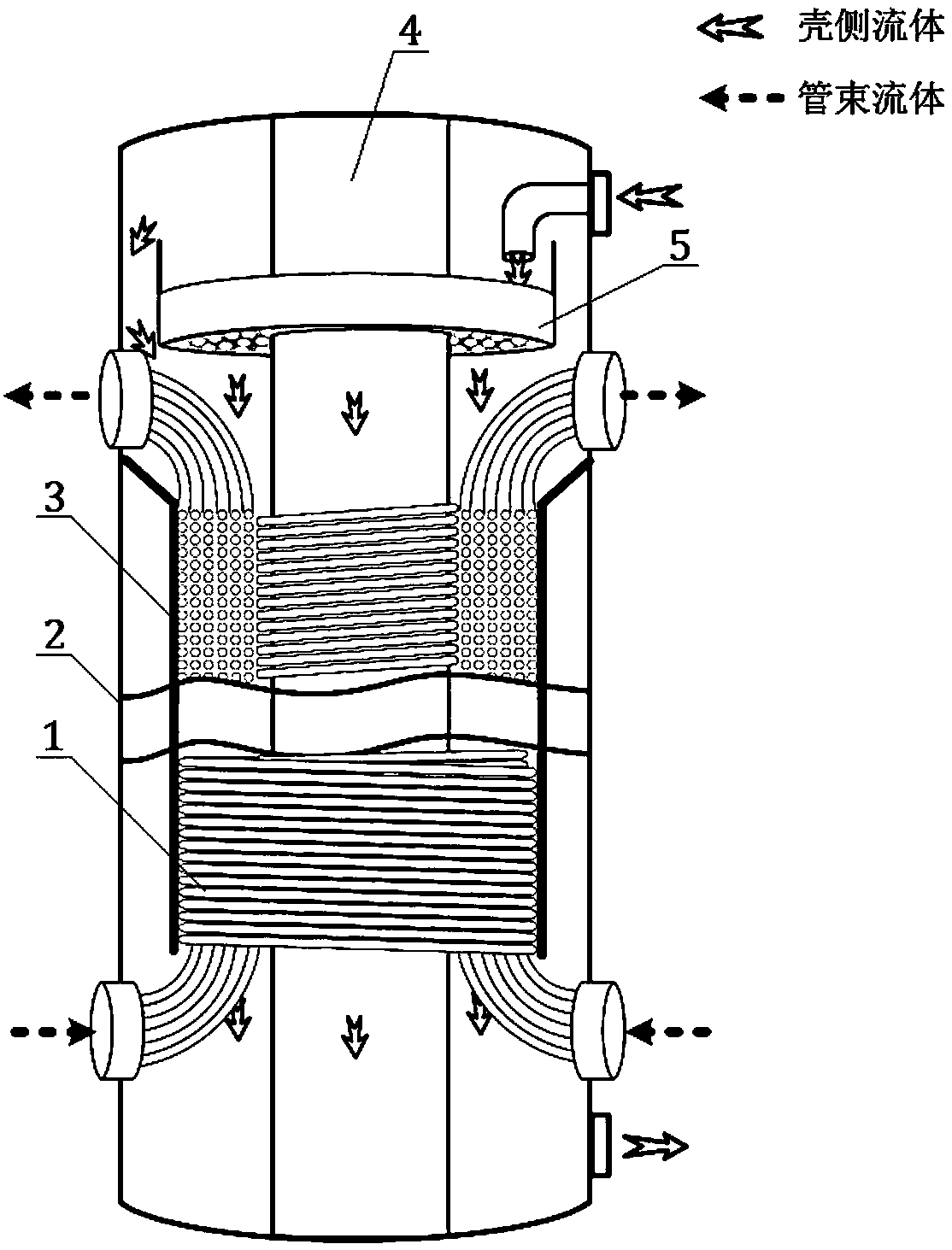

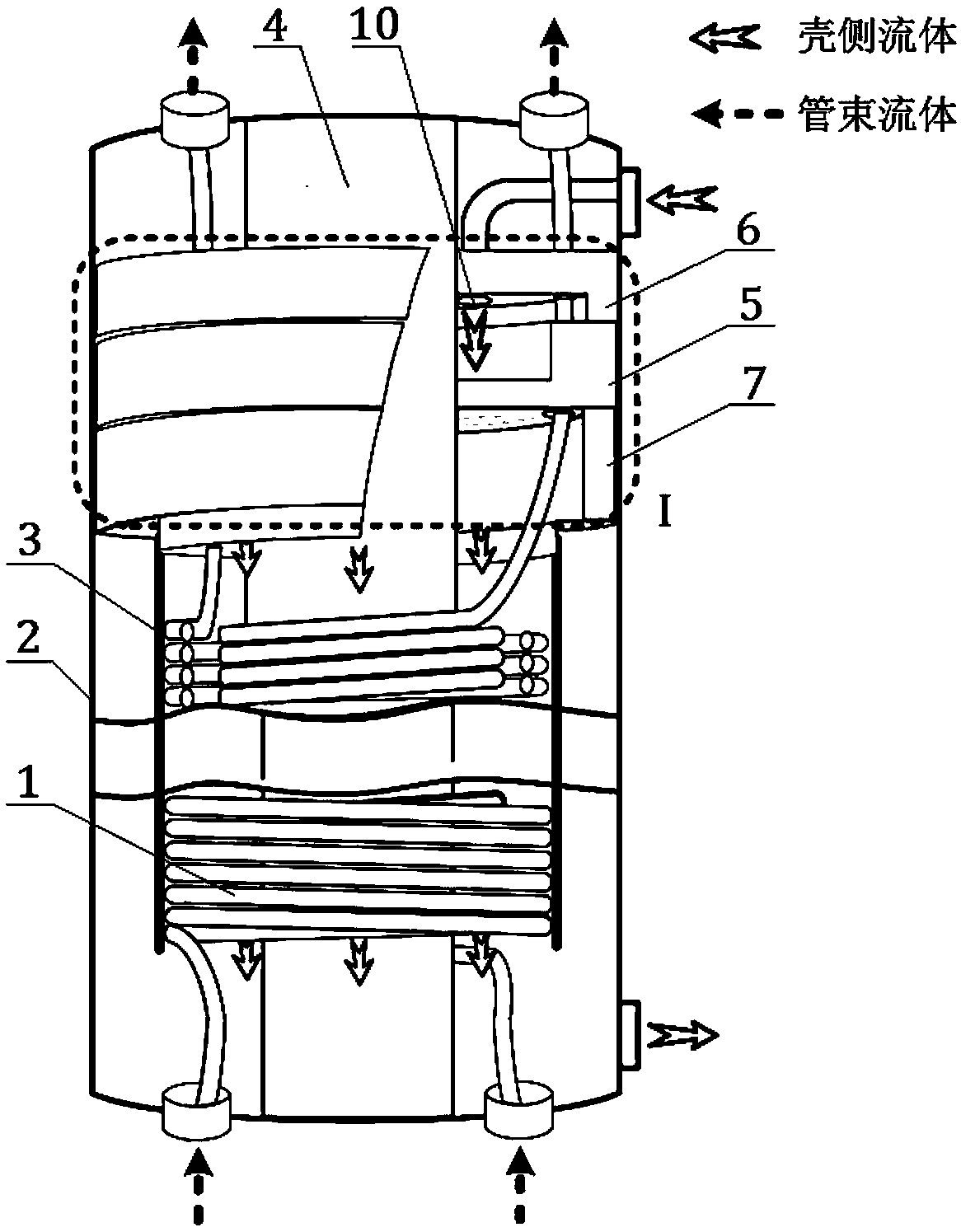

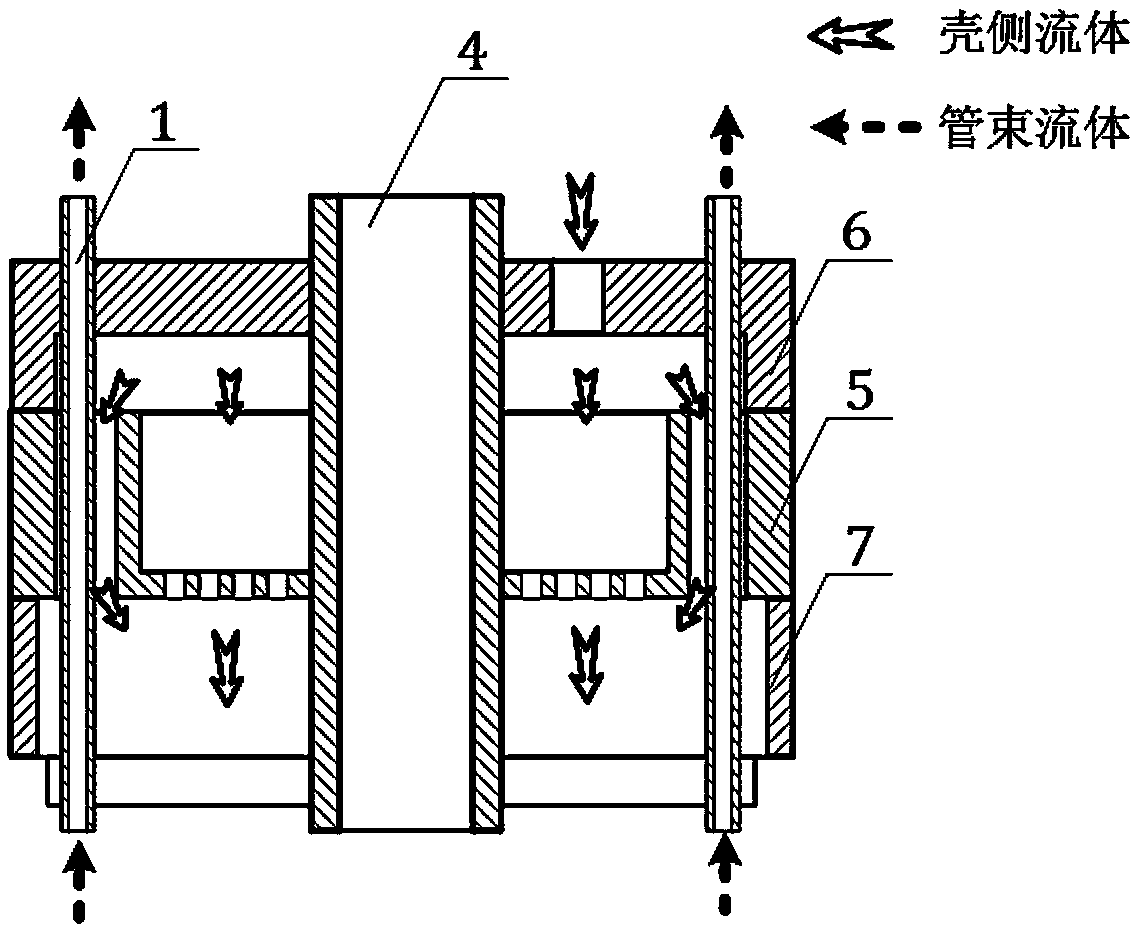

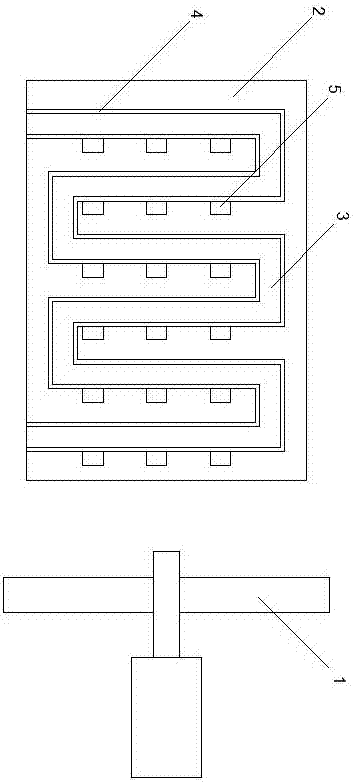

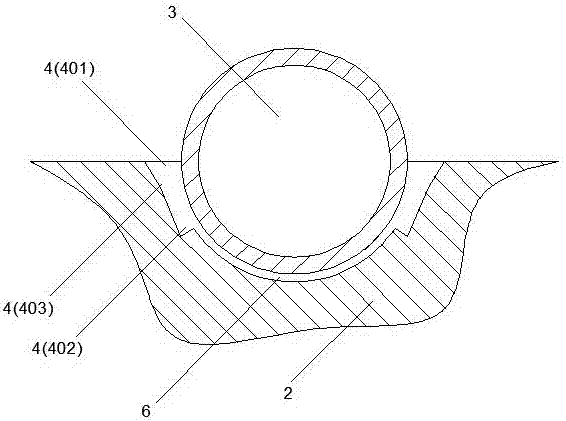

Tube-wound heat exchanger with separated core and shell

ActiveCN106524789BHeat exchanger casingsStationary tubular conduit assembliesEngineeringLiquefaction

Owner:SHANGHAI JIAO TONG UNIV +1

Cooling device in natural gas liquefaction technology

InactiveCN107356048AImprove cooling effectReduced power stateSolidificationLiquefactionAir pumpCooling effect

Owner:陈美廷

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap